In today’s delivery-driven economy, managing the logistics of heavy and bulky cargo efficiently is critical for business success. The truck bed lift gate has emerged as a pivotal tool that transforms how businesses handle loading and unloading tasks. This article explores the mechanisms and advantages of hydraulic lift gates, delves into their vital safety features, analyzes their economic implications, and highlights various industrial applications through compelling case studies. Each chapter interlinks to provide a comprehensive understanding of how integrating lift gates can significantly enhance operational efficiency and safety in freight transportation.

Raising Efficiency: The Mechanisms and Advantages of Hydraulic Truck Bed Lift Gates

Heavy goods move through modern supply chains with a quiet, persistent efficiency that depends on a thousand small decisions. Among them, the choice and use of a hydraulic truck bed lift gate stands out as a quiet enabler—an unobtrusive, rugged mechanism that turns a dock-less curb into a practical loading zone. For fleets delivering to locations without loading docks or forklift access, a lift gate is not a luxury but a core part of the safety and reliability equation. The scene is familiar: a driver arrives at a curb, releases the tailgate, and within moments a platform rises or lowers, carrying a bulky item from ground to bed, or from bed to ground, with a controlled, gentle motion. The lift gate does the heavy lifting, so workers can focus on secure placement, proper strapping, and careful maneuvering around obstacles. The result is a workflow that scales with demand, reducing the need for multiple people on the ground, minimizing fatigue, and shrinking the time a single delivery takes from curb to customer hands.

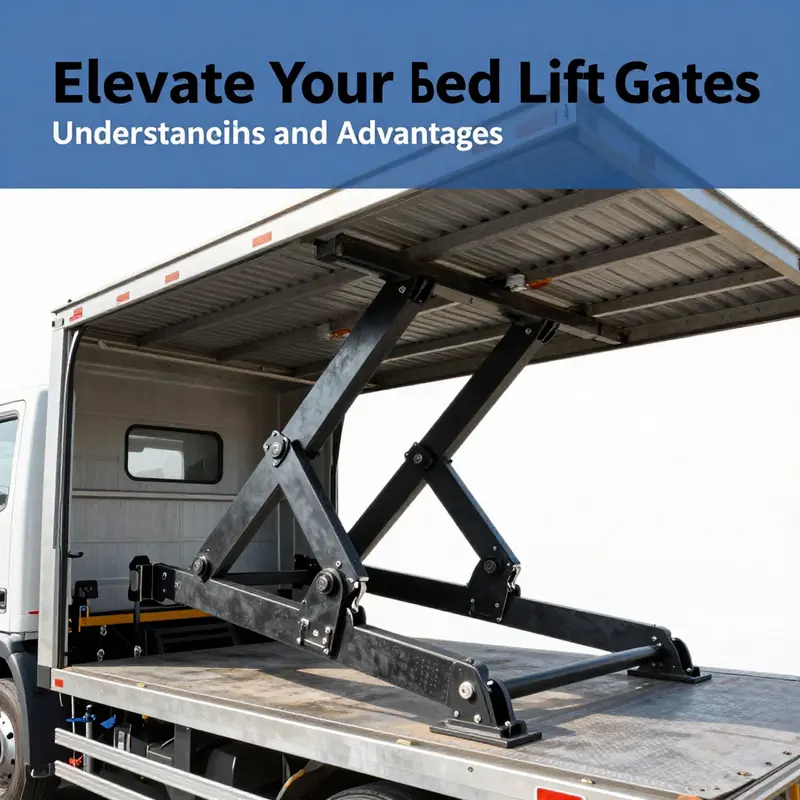

Beneath the clean, dependable action of a hydraulic lift gate lies a compact system of components that work in concert to translate fluid pressure into precise mechanical movement. The heart of the mechanism is a hydraulic cylinder, a stout tube housing a piston and rod. When the operator drives action from the cab, an upstream hydraulic pump pushes incompressible oil into one side of the cylinder while venting through the opposite side. The piston extends, the rod travels, and the gate begins its ascent. Reversing the flow retracts the rod and lowers the gate with the same measured, steady rhythm. This is not a simple latch or lever; it is a carefully tuned, pressurized system whose performance depends on consistent fluid integrity and carefully matched seal tolerances. The hydraulic pump itself can be powered in one of a couple of ways. In many fleets, the pump is belt-driven from the truck’s engine, which ensures a robust supply of flow during high-demand periods. In others, an electric motor powers a compact pump, a setup that can offer quieter operation and reduced parasitic load on the engine. Either way, the pump draws hydraulic fluid from a reservoir, a sealed oil tank that stores the medium by which force is transmitted. The fluid’s incompressibility is essential. It means that a small movement in fluid volume results in a predictable, linear rise or descent of the gate, which translates into reliable load control and precise staging for unloading or reloading.

Fine control comes from the directional control valves—solenoid or manual valves that direct pressurized fluid to the appropriate side of the cylinder. When the operator activates the control, the valve channels the flow toward the chamber that drives the lift or commands the gate to descend. The return line completes the circuit, with the fluid returning to the reservoir as needed. Beyond the pump and the cylinder, flexible hoses and rigid tubes keep the circuit sealed and leak-free, guiding fluid along a path designed to tolerate outdoor conditions, temperature swings, and routine vibrations from road use. A well-designed system includes safety features that protect operators and bystanders. Relief valves prevent over-pressurization, which could otherwise damage seals or gear trains. Check valves prevent unintended movement if a line experiences a temporary pressure drop, and limit switches or sensor arrays stop the gate at its fully open or fully closed positions. Taken together, these components create a dependable, predictable lift that operators can trust, even after thousands of cycles.

The operator’s experience with a hydraulic lift gate is marked by safety, control, and efficiency. When the switch is engaged, the truck’s cab becomes the control room for a small, controlled spectacle of physics in action. The gate slowly begins its ascent, and a technician watching the scale of the cargo beyond the platform gains confidence knowing that the movement is smooth and deliberate. The motion is not merely mechanical; it is guided by a system designed to dampen shock and reduce dynamic load transfer that could otherwise shift items or cause damage. A modern lift gate offers more than a simple up-and-down motion. Some models feature canting that allows the platform to tilt to a dumping angle for bulk unloading, a feature that can simplify the handling of loose materials or bulk items without requiring manual tipping. This kind of capability is particularly valuable in environments where the destination area is uneven, cluttered, or lacks easy access to the truck itself. The gate’s lowering sequence mirrors the ascent in safety and precision. The operator can gradually lower the platform to ground level, lowering even heavy cargo as a controlled, measured process.

The advantages of hydraulic lift gates extend beyond the immediate act of lifting. First and foremost, safety becomes a governing design principle. Eliminating the need for workers to climb onto boxes or pallets reduces exposure to falls, strains, and other injuries. The risk of back injuries or slips is significantly diminished when a single operator can manage the entire load from the ground, with the platform doing the heavy lifting. This is especially critical in urban settings, where sidewalks and streets present additional hazards. The gate’s movement is predictable and repeatable, which means fewer unexpected jolts that could damage sensitive items or shift a load mid-transfer. The second major benefit is efficiency. A typical lift gate can move far more weight in a shorter window than manual handling across multiple crew members. A single operator can place a pallet or a loaded skid onto the bed, secure it, and be ready to roll in the time it would take a crew to perform the same task without a lift gate. In fleets where every minute matters, the time saved translates directly into higher daily throughput and the ability to serve more customers with the same equipment.

Load capacity, of course, remains a defining metric. Lift gates are engineered to handle heavy items—furniture, appliances, industrial equipment—where the mass would otherwise require mechanical assistance. The ramped, platform-based design is not just about lifting; it is about respecting the product’s integrity by keeping it level, supporting it across its breadth, and reducing the likelihood of vertical shocks that can happen with rough handling. The consequence is a gentler handoff at the customer site, which minimizes product damage and the costly returns that sometimes accompany mishandling. In addition to raw strength, hydraulic lift gates offer smooth, controlled dynamics that prevent abrupt starts or stops. This is essential when delicate equipment or dense, awkward shapes are involved, as it helps preserve finishes, packaging, and the item’s overall condition. The net effect is a logistics asset that aligns with the modern emphasis on safety, reliability, and customer satisfaction.

There is also a practical economic calculus to the lift gate decision. While there is an upfront cost associated with purchasing or retrofitting a truck with a lift gate, the ongoing labor savings can be substantial. Fewer personnel may be required on site for each delivery, and the risk of injury-induced downtime decreases. Efficiency gains can shorten delivery windows and enable more predictable service levels, which, in turn, can support contract terms and service-level agreements with customers. At the same time, fleets need to manage maintenance and inspection routines to prevent system degradation. Minimal, routine checks—fluid levels, hose integrity, seals, and sensor calibrations—help maintain peak performance. Without proactive maintenance, a leak or seal failure can erode the very efficiency gains that lift gates deliver, turning a robust asset into a source of delays and risk. Proper upkeep also means inspecting the truck’s electrical or belt-driven drive system that powers the pump, ensuring alignment with the vehicle’s powertrain and reducing the likelihood of unexpected outages in the field.

The design choices behind hydraulic lift gates also influence how fleets deploy them. Hydraulic systems are highly favored for heavy-duty applications due to their robustness and reliability in a wide range of temperatures and environments. They are well suited to the rough-and-tumble realities of construction sites, agricultural supply lines, and debris-laden waste management routes. Electric and manual variants exist, but their suitability tends to wane as payloads grow or as work cycles require frequent, heavy lifting. Hydraulic systems deliver a more consistent, higher-load performance with smoother operation, which is why they remain the dominant choice for demanding applications. Yet every fleet must weigh the total cost of ownership, including maintenance, potential fluid leaks, and the need for periodic component replacements as technology evolves. The choice ultimately comes down to aligning the lift gate’s capabilities with the job profile: the typical weight range, frequency of use, the height and surface grade of loading zones, and the expected exposure to dust, moisture, and temperature extremes.

To maximize safety and efficiency, operators should treat the lift gate as part of a holistic loading process. They must visually verify a clear area around the tail end of the truck to avoid pinning bystanders or equipment, confirm that cargo is properly secured with rated restraints, and ensure that the gate area is free of obstructions before raising or lowering. The door’s surface should be clean and dry to prevent slips, and pallets or crates should be oriented to align with the platform’s width and stance. It is also prudent to check the gate’s limit switches and sensors before each shift to ensure that the system’s automatic halts function properly. These checks, while simple, form the bulwark against accidents and damage, creating a cycle of safety that becomes second nature to a trained operator. The practical lessons here are enduring: invest in regular preventive maintenance, train operators to follow standardized procedures, and treat the lift gate as a critical component of the delivery workflow rather than a peripheral add-on.

In the broader context of fleet operations, the lift gate’s role extends to the planning stage of shipments. For Less Than Truckload (LTL) shipments or routes that routinely encounter curbside deliveries, confirming lift gate availability in advance is essential. Some carriers and shippers explicitly request lift gate service to ensure that the delivery site can handle the weight and height of the load. When a lift gate is required, the scheduling and communication around the delivery should reflect this need so that the receiving party is prepared. The logistics discipline of noting lift gate requirements in shipment paperwork reduces the risk of failed deliveries and the associated costs. This emphasis on preparedness and clear communication complements the safety and efficiency gains provided by the hydraulic system itself, creating a cohesive, dependable delivery experience that aligns with modern expectations for speed, predictability, and care with customer goods.

As the industry continues to evolve, attention to lift gate technology is shifting toward smarter maintenance and more refined integration with the vehicle’s broader telemetry and diagnostics. Predictive maintenance, remote monitoring of hydraulic fluid temperatures, and sensor-based diagnostics can help fleets anticipate issues before they disrupt schedules. The most forward-looking operations invite a culture that treats the lift gate not as a standalone gadget but as a connected part of a fleet’s safety, efficiency, and service quality profile. In this light, the hydraulic truck bed lift gate is more than a tool for moving heavy items; it is a practical embodiment of safer, smarter, and more reliable material handling. Its continued relevance rests on thoughtful selection, careful integration with the vehicle and the loading process, and disciplined maintenance routines that preserve performance over the long haul.

Further reading and resources can offer deeper technical context for those who want to see the broader picture of hydraulic systems in commercial vehicles. For a concise overview of liftgates and related equipment, see liftgates. liftgates. This page helps connect the mechanical principles described here with practical, on-the-ground guidance that drivers and shop staff can apply when selecting, testing, and maintaining lift gate equipment. In parallel, operators should consider how the lift gate interacts with other cargo-handling devices on a given truck, how it affects loading dock readiness, and how it supports a broader goal of safer, more efficient deliveries. The overarching idea is simple: the hydraulic lift gate blends physics and practicality to translate effort into safety, speed, and reliability for every curb-renowned delivery.

External resource for deeper hydraulics concepts and system design can be consulted at the following external reference: https://www.boschrexroth.com/en/products/hydraulics

Raising the Standard: Safety Features That Make Truck Bed Lift Gates a Safer Cornerstone of Modern Freight

A truck bed lift gate is more than a mechanical add-on; it is a carefully engineered interface between human effort and heavy cargo. In fleets where loading docks are scarce, where street-side deliveries and urban constraints dominate the day, the lift gate becomes a critical arbiter of safety, pace, and damage control. The chapter you are reading places safety features at the center of the design and operation narrative because without reliable protective systems, the efficiency gains of a lift gate can be overshadowed by risk. When drivers, loading crews, and nearby bystanders share the same space, a thoughtful blend of automation, sensing, and control becomes not just a nicety but a necessity. To appreciate how these components fit together, consider how each feature translates into fewer injuries, less product damage, and smoother handoffs from ground to truck and back again. For a practical overview of the equipment’s landscape, you can consult our liftgates guide, which situates these safety functions within broader fleet considerations. liftgates guide

Among the most foundational safety characteristics is the controlled, automated lifting mechanism. In traditional manual handling, heavy or bulky items invite the risk of musculoskeletal strain, accidental drops, and missteps that can cascade into injuries or property damage. A properly designed lift gate uses hydraulic or electric power to provide smooth, predictable motion. When the platform rises or descends, it follows a carefully engineered velocity profile that minimizes momentum transfer and helps an operator maintain stable footing. The automation removes the need for improvised lifting techniques, enabling a more repeatable, verifiable process. The benefit is not only physical safety; it is also procedural clarity. Operators know what to expect from each lift, which reduces the cognitive load in a high-stakes environment where one misstep can affect dozens of pallets or delicate medical devices.

Integrated with this mechanism are safety interlocks and sensors that create a digital perimeter around risk. Modern lift gates are equipped with proximity and obstacle-detection sensors that monitor the path of the platform. If something or someone intrudes into the zone as the gate moves, the system halts and, depending on the installation, may reverse to a safe position. This automated safeguard is particularly valuable in busy docks, narrow driveways, or urban loading zones where pedestrians or other equipment frequently intersect the lift’s envelope. The interlock logic embodies a simple yet powerful principle: do not proceed when the environment is not clear. It is a proactive approach that shifts responsibility away from the operator’s reflexes toward a consistent, machine-aided decision. In practice, this means fewer crushing hazards and fewer pinch points, especially around the platform edge, where workers often stand during a lift or unload.

Beyond obstacle avoidance, the gate’s compliance with industry safety standards adds another layer of reliability. Reflective strips, proper brake lighting, audible warnings, and conspicuous signage help ensure that the lift gate and its trailer remain visible to other road users, even in low-light conditions. Standardization in signaling and guards helps reduce the ambiguity of the vehicle’s intent. A bright, clear warning system—accompanied by standard operator procedures—lets nearby drivers and pedestrians anticipate the lift’s operation. This visibility is essential for preventing accidental contact and supporting safe handoffs on busy streets. When fleets invest in safety-compliant features, they are also committing to a baseline of predictable behavior that supports both local regulatory expectations and broader safety culture.

Material durability and construction quality matter as much as sensors and signs. Lift gates must endure repeated cycles of heavy loads, exposure to the elements, and the grind of daily logistics. Durable, corrosion-resistant materials—such as reinforced steel and protective coatings—help ensure the platform remains plumb and reliable under load. A robust frame reduces the risk of structural failure that could lead to sudden drops or unexpected halts in movement. In addition to strength, thoughtful design includes protective guards, non-slip surfaces, and secure anchor points for cargo. When the platform and its supports resist corrosion and fatigue, there is less chance of failure in the field, which translates into safer operation and fewer emergency interventions.

User-friendly controls and emergency stop functions are the human-facing side of lift-gate safety. Clear, intuitive controls reduce the likelihood of operator error, a factor that remains central to any operational safety assessment. A single, unmistakable emergency stop button provides an immediate outlet to halt motion in the event of a malfunction, misalignment, or an external hazard. The control layout should be accessible to the operator, with distinct tactile feedback and fail-safes that prevent accidental activation. In well-designed systems, the emergency stop is not a last resort but an integrated feature that reinforces a safety-first mindset. Operators trained to treat the stop as a routine safety check can prevent cascading incidents during complex loading operations.

The broader picture of safety in lift gates also involves ongoing maintenance, inspection, and operator training. A mechanically reliable system is only as good as its upkeep. Regular checks for hydraulic fluid levels, hose integrity, seals, and mounting hardware help prevent leaks, pressure drops, or misalignments that could compromise safety. A proactive maintenance routine catches wear before it becomes a hazard, shrinking the likelihood of a sudden platform drop. Visual inspections, paired with functional testing, ensure that sensors stay responsive and that interlocks are calibrated to the correct thresholds. In addition to technical upkeep, fleets must invest in training that emphasizes clear communication, coworker awareness, and standard operating procedures. Training should cover not only how to operate the lift gate, but how to coordinate with the ground crew, dock personnel, and drivers approaching the vehicle from other directions. The safety value of training multiplies when it is embedded in a wider safety culture that treats every loading sequence as a potential risk scenario rather than a routine task.

The conversation about safety would be incomplete without recognizing the operational environment in which lift gates function. Where dock access is limited or non-existent, the lift gate becomes the primary mechanism for bridging ground-level handling with a truck bed. In those contexts, the risk profile shifts: uneven ground, sloped terrain, or uneven palettes demand additional care. Operators must assess load distribution, securing methods, and the ability to maneuver pallets safely onto the platform. The controlled, automated lifting mechanism helps here by providing stable, vertical movement rather than manual lifting, which would concentrate strain on individual workers. Yet this stability should not mask the need for situational judgment. A smart operator remains mindful of wind, weather, and surface conditions that could alter a pallet’s stability during lift and transfer. The cadence of a typical delivery—unloading one large item; repositioning a second; and then returning to the truck for another load—becomes a rhythm governed by safety checks as much as by time constraints. In this sense, the lift gate’s safety features act as a practical embodiment of risk management at the point of load transfer.

The integration of safety features is not a static proposition. Advances in sensing, diagnostics, and control algorithms continually refine how lift gates respond to real-world challenges. Some designs incorporate redundancy for critical safety paths, so that if one sensor becomes inactive, another mechanism maintains protective behavior. Diagnostic dashboards and remote monitoring offer fleets a way to observe gate performance across dozens of vehicles, identify patterns that precede failures, and schedule maintenance before incidents occur. This proactive stance toward safety reflects a shift from reactive fixes to preventive reliability, a transformation that reduces both serious injuries and costly downtime. The result is a system that not only lifts cargo but also elevates the safety expectations of every person involved in the delivery process.

From a fleet-management perspective, the value of safety features extends into cost control and logistics efficiency. While some operators view safety add-ons as optional or as an expense line, the broader calculus reveals substantial long-term savings. Fewer injuries mean lower workers’ compensation costs and less downtime, which translates into steadier delivery windows, more predictable routes, and improved customer satisfaction. Safe loading practices also decrease the risk of product damage during handling, a factor that becomes especially important for high-value items such as appliances, medical equipment, or industrial components. When a lift gate operates with confidence and clarity, it enables a driver to focus more on the sequence of steps required to complete the delivery, rather than managing physical risks. In turn, this focus reduces the cognitive load during critical moments, allowing the driver to coordinate with the warehouse staff and customers more effectively.

Cost considerations inevitably accompany any discussion of safety features. The initial investment in a lift gate with advanced interlocks, sensors, and durable construction may be higher than more basic configurations. However, the lifetime cost of ownership often benefits from lower maintenance variability, fewer emergency interventions, and extended platform life. Fleet operators must weigh the tradeoffs between hydraulic versus electric drive systems, the level of sensor sophistication, and the redundancy mechanisms that align with their operating environments. In urban fleets with frequent, rapid cycles, a robust hydraulic system paired with well-calibrated sensors can provide the balance of power, precision, and safety that keeps a delivery schedule on track. In long-haul or regional fleets, the emphasis might shift toward energy efficiency and ease of maintenance, while still preserving essential interlocks and emergency controls. The safety architecture of a lift gate, thus, is not a single feature but an integrated system designed to align with the fleet’s risk tolerance, route structure, and workforce training.

Safety in lift gates also has a communications dimension that transcends the equipment itself. Clear, consistent signaling between the driver, dock staff, and customers is essential for a smooth transfer of goods. A well-designed process includes verbal cues, hand signals where appropriate, and documented checklists that ensure everyone understands the sequence of operations. When all participants know who is responsible for monitoring the platform, who will secure the load, and how the transfer will unfold, the probability of miscommunication drops dramatically. In this sense, safety features extend beyond the physical device to the social choreography of loading operations. The lift gate becomes a shared tool that requires coordination, discipline, and respect for boundaries around moving machinery. When such coordination exists, the risk of accidents—such as a finger pinch during loading or a pallet slipping from a poorly secured strap—declines sharply.

Finally, the future of safety in truck bed lift gates is likely to be shaped by smarter diagnostics and more integrated fleet technology. As sensors become more compact and more capable, engineers can embed health monitoring directly into the gate’s control software, delivering real-time alerts about wear, misalignment, or hydraulic pressure anomalies. Remote diagnostics can reduce on-site maintenance visits, enabling technicians to pre-stage parts and schedule work during off-peak hours. This evolution promises to keep lift gates not only safe but also highly available, ensuring that a vehicle is ready to perform when the next loading window appears. The net effect is a safer, more reliable asset class within the freight ecosystem, one that helps drivers, warehouses, and customers alike participate in a flow that respects people as much as it respects payload.

For readers seeking technical specifics or product-level details, the broader safety landscape includes standards and specifications that firms often consult when selecting lift gate systems. A widely referenced external resource provides a deeper dive into hydraulic tailgate lift options and their application to box trucks. While the exact configurations vary, the underlying safety ethos remains consistent: reliable motion, clear signaling, protective interlocks, sturdy materials, and ongoing maintenance. If you are evaluating lift gates for a fleet, consider how each safety feature translates into real-world outcomes—injury reduction, product integrity, and predictable delivery performance. This is not merely a mechanical choice; it is a strategic decision about how a company protects its people, its cargo, and its reputation in a demanding market.

External resource reference: https://www.alibaba.com/product-detail/Hydraulic-Tailgate-Lift-26-ft-Truck-Lift_1600584739736.html

Bed Gate Economics: The Hidden ROI of Truck Bed Lift Gates in Modern Freight

Every delivery route begins with a decision about how goods will move from curb to curb. For fleets facing tight urban streets, warehouses without docks, and schedules that press drivers into back-to-back drops, the choice to add a truck bed lift gate is a strategic one. It is not a flashy gadget but a capital asset that shifts how work gets done, how people are protected, and how money flows through the business. When a lift gate is properly integrated into a truck, it changes the entire arithmetic of a delivery operation: the load that once required two people to lift becomes a one-person operation, the risk of injury declines, and the clock on every stop starts ticking at a different rate. The shift is not purely mechanical; it is a recalibration of risk, cost, and reliability across the logistics chain.

Operational efficiency gains come from a combination of mechanical advantage and better coordination with the rest of the supply chain. The lift gate acts as a controllable lever that transforms ground-level access into a predictable, repeatable process. Items that previously demanded a forklift on site or a second crew now move through a single driver’s hands, with the gate performing the heavy lifting. For urban fleets, where dwell time at customers equals hours saved per day, even small reductions in unloading time accrue to meaningful gains across hundreds of stops per week. The math is straightforward: if a single stop takes two minutes less due to a smoother lift and lower manual handling, a fleet saves tens of hours per truck per year. Multiply that by the number of vehicles, and the economic signal becomes clear. This is not merely about speed; it is about reliability. Consistent unloading times reduce the likelihood of schedule slips that cascade into late deliveries, missed windows, and penalties from customers who demand precision. In practice, the lift gate becomes an anchor for planning, ensuring that the end of the route aligns with the start of the next cycle rather than fraying under accommodateable delays.

Labor costs are the most visible line item in last-mile budgeting. Lift gates reduce the physical strain on workers, which translates into lower risk of musculoskeletal injuries—a major driver of workers’ compensation claims and healthcare costs. In environments where heavy items, such as appliances or bulk materials, move daily, the financial impact of preventing a single back injury can be substantial. The broader benefit is that workers are less fatigued by manual lifting, leading to steadier performance later in the day. When a fleet calculates its true labor cost, it must account not only for wages but also for the risk premium that accompanies physically demanding tasks. By providing a mechanical assist, lift gates can lower that premium over time, even if the upfront investment requires careful budgeting. The practical outcome is a leaner crew requirement for certain shifts and the ability to deploy labor more strategically across routes, rather than simply adding more bodies to the dock. This shift also supports a more predictable payroll and scheduling model, reducing overtime and improving labor plan stability across seasons with varying demand.

Beyond the numbers on paychecks, lift gates contribute to a healthier, safer work environment. Ergonomics programs target the risks associated with repetitive lifting, awkward postures, and the unpredictable nature of loading bulky goods. A 2020 study on ergonomic programs for truck loaders showed that while initial investments matter, the long-run dividends come in the form of lower injury rates, reduced downtime, and higher worker satisfaction. When teams feel that safety is built into the equipment they operate, morale improves and retention follows. Of course, the effect on safety is not only about the worker; it also reduces the exposure of the company to accident investigations, regulatory scrutiny, and the reputational cost that comes with a high injury rate. Lift gates become a practical embodiment of a safety-first culture, signaling that the organization values people as much as profits. The result is a workplace where frontline staff view their equipment as a partner in safe delivery rather than a barrier to efficiency. This perception can translate into more careful handling of items, fewer near-misses, and a broader acceptance of preventive maintenance as part of daily routine rather than a showpiece maintenance event.

Technological integration often elevates the value proposition of lift gates. Telematics devices that monitor usage, hydraulic pressure, cycle times, and maintenance intervals turn a simple lifting device into a data-enabled asset. When fleet managers see patterns in how often the gate is used at certain routes or times of day, they can optimize driver assignments, adjust maintenance schedules, and refine loading sequences to minimize delays. The data also supports proactive upkeep, preventing abrupt gate failures that could strand a truck at a curb or warehouse dock. In such configurations, lift gates mesh with broader fleet-management ecosystems, contributing to smoother operations and more predictable performance. In a market where insurance costs can be influenced by driver behavior and vehicle reliability, these integrated capabilities can translate into real dollars saved on premiums, sometimes cited as reductions up to a quarter of insurer-related expenses when fleets adopt a coherent safety and telematics program. The result is a cycle of continuous improvement, where every lift cycle feeds into better route planning, more accurate load projections, and a clearer view of asset utilization across the fleet. Fleet operators who embrace this convergence of hardware and data typically report a smoother handoff between loading and transit, fewer contingencies at customer sites, and a more confident forecast of service levels for key accounts.

From an ROI perspective, the calculus is a blend of upfront purchase, ongoing maintenance, and the downstream effects on uptime and service quality. Lift gates require routine inspections, hydraulic fluid management, seal replacements, and occasional component servicing. These maintenance activities incur costs, but they prevent more expensive downtime and more severe safety incidents. While exact ROI figures vary by fleet, geography, and the types of loads handled, the experiential evidence points to a clear net benefit over standard pings of repair costs, lost business due to late deliveries, and injury-related expenses. The time horizon matters: fleets that view the lift gate as a strategic asset rather than a one-off upgrade tend to realize payback across a shorter cycle, especially when the gate is paired with standard operating procedures that emphasize safe operation and proactive maintenance. The result is not merely a reduction in direct costs; it is an uplift in service reliability that translates into improved customer trust, higher repeat business, and the ability to command pricing or service levels that reflect the enhanced performance. Maintenance cadence—how often fluids are topped, seals replaced, and calibrations checked—becomes a staple of the route plan, not a reactive afterthought.

Viewed through a wider economic lens, lift gates contribute to efficiency at scale within freight networks. The economics of intercity freight emphasize the leverage gained when loading and unloading frictions shrink. As shipments move through hubs and across last-mile networks, every minute saved at the curb compounds into meaningful effects on fleet utilization, route planning, and asset turnover. The literature on economies of scale in freight transportation underscores how small efficiency gains accumulate across millions of miles and thousands of loads. In practice, lift gates are one piece of a larger puzzle: a carefully engineered set of tools that reduce labor intensity, improve safety, and enable a more predictable delivery schedule. The synergy with other fleet enhancements—ranging from optimized routing to standardized cargo handling procedures—creates a durable competitive advantage for operators who invest in such assets. For fleets seeking deeper context on the macroeconomic influences on freight, broader studies provide a backdrop for how these micro-efficiencies fit into the industry’s longer arc. As these assets mature, their value is crystallized not only in the immediate cost savings but in the resilience they confer during peak seasons, supply shocks, and evolving regulatory expectations.

To ground this discussion in practical terms, many operators turn to resources that map lift gate adoption to concrete fleet configurations and service models. For fleets evaluating this upgrade, our dedicated page on liftgates outlines how these platforms integrate with standard truck configurations and loading workflows. This resource helps translate the abstract economics into a concrete plan for procurement, training, and maintenance scheduling.

In closing, lift gates are not just hardware; they shape how a fleet thinks about efficiency, safety, and resilience. They alter the calculus of labor, the leverage of capital assets, and the predictability of service delivery. When deployed with thoughtful maintenance, informed by data, and aligned with ergonomic best practices, truck bed lift gates become a central pillar of a modern freight operation. They offer a measurable pathway to lower injury costs, faster turnarounds, and a steadier revenue stream in the face of volatile markets. The economic narrative is not about the cost of the gate alone; it is about how the gate changes every subsequent decision—from route design and staffing to insurance considerations and customer commitments. For readers seeking broader context on the industry-wide implications, a related study provides additional insights into how efficiency and scale interact within freight networks: https://www.sciencedirect.com/science/article/pii/S0965856425001347

Bridging Ground and Cargo: The Industrial Impact of Truck Bed Lift Gates

A modern fleet often looks lean and efficient until the rear doors swing open and reveal the real workhorses of the operation: truck bed lift gates. These hydraulic or mechanical platforms are more than just appendages; they are disciplined interfaces that translate ground-level gravity into controlled, safe, and repeatable loading and unloading sequences. In environments where loading docks are scarce or absent, the lift gate becomes the difference between a predictable, injury-free operation and a risky, time-draining struggle with heavy cargo. When a driver slides a pallet from the curb onto a platform that rises smoothly to the bed, the act feels almost routine, but the behind-the-scenes engineering and operational discipline are anything but incidental. The lift gate’s function—lifting from ground to bed and lowering back down with precise control—touches every corner of industrial logistics, from cadence and speed to safety, damage prevention, and total cost of ownership. It is the quiet engine of efficiency in sectors that move bulky, heavy, or awkward items at scale, and it reshapes how companies think about route planning, worker safety, and the balance between capital investment and service reliability.

In the realm of manufacturing and heavy machinery distribution, lift gates prove indispensable. Finished equipment such as industrial motors, generators, or sizable steel components must travel from production lines to customer sites with nothing left to chance. A Midwest-based manufacturing operation adopted hydraulic lift gates across its delivery fleet and recorded a measurable shift in performance: average delivery times dropped by about 35 percent, and the fleet eliminated more than 200 manual handling incidents each year. The result was not only faster turnover but a more predictable safety profile. The lift gate neutralizes a line of risk that historically grew when workers lifted items from the truck floor or blocked lanes with manual handling. In such settings, the gate becomes a scalable solution, capable of supporting high-volume, repetitive loads without sacrificing control or precision. Its strength is not simply raw horsepower; it is the fidelity of the movement, the steadiness of the platform as it rises and descends, and the synchronization with the driver’s workflow.

Construction materials present a parallel story of scale and constraint. Drywall, roofing, concrete blocks, piping—these are heavy, awkward, and frequently awkward to maneuver in tight spaces. A national building supply chain found that after equipping its delivery trucks with scissor-style lift gates, driver-reported back injuries declined markedly, by roughly forty percent. The faster unload cycles translated into a measurable capacity gain, with daily delivery volumes increasing by a quarter. The gains extend beyond safety metrics; the system reduces dwell time at job sites and minimizes the chain of manual handling steps that can degrade material condition, laddering damage risks to packages, or misplacement on crowded job sites. In high-demand construction corridors, the lift gate ensures that crews can receive materials in a single, smooth event instead of a sequence of stops and adjustments.

Even in the perishable corridors of food and beverage distribution, lift gates contribute to both product integrity and operational tempo. Temperature-controlled fleets bring additional constraints, where every minute that a product spends exposed to ambient temperatures risks quality degradation. An industry-leading Northeast distributor moved to electric lift gates on its refrigerated fleet, with benefits that extended beyond safety. The gates cut dwell time at remote retail locations, enabling cooler handoffs and reducing the time products spend outside controlled environments. The result was not only better product condition but a streamlined unloading workflow at sites without docks, translating into a more predictable delivery window and reduced spoilage risk during handoffs. In the cold chain, timing is part of the product’s value, and the lift gate becomes a critical instrument for safeguarding that value while maintaining route reliability.

Medical equipment logistics adds another compelling dimension. Hospitals and healthcare systems rely on the timely, damage-free delivery of sensitive devices. A national medical supply organization examined its use of lift gates that included anti-slip platforms and load sensors. The data showed a substantial reduction in both product damage and delays, with potential damages and related interruptions avoided to the tune of more than a million dollars in a single year. In environments where devices are fragile and the stakes are high, the ability to place a heavy instrument with surgical precision onto a raised bed, and then lower it safely onto a receiving cart or storage rack, is a meaningful risk manager. The lift gate provides not only physical support but also a consistent handoff protocol—an essential characteristic when equipment originates in a controlled manufacturing area, moves through a distribution network, and lands in a clinical setting where downtime translates into treatment delays.

Across these varied industries, several common threads emerge about how lift gates function as strategic assets rather than mere conveniences. First, the choice of mechanism matters. Hydraulic systems typically deliver the higher load capacities and a robust feel that suits heavy, repetitive work. Electric lift gates, by contrast, offer quieter operation and lower maintenance footprints in certain use cases, particularly where noise or energy efficiency is a concern. The decision should hinge on the nature of the loads, the typical working environment, and the overall maintenance philosophy of the fleet. The best practice is to couple the chosen system with a thoughtful safety architecture. This includes features such as emergency stop functions, overload protection, obstacle detection, and automatic reversal when contact occurs. Standards alignment, such as ISO 16872 for lift gate safety, provides a baseline that ensures consistent performance, but the real value comes from tailoring these safeguards to the fleet’s daily rhythms and site realities.

Maintenance emerges as the second crucial pillar. Lift gates are not passive frames; they are active systems whose reliability depends on regular care. Hydraulic configurations require periodic fluid checks, filter changes, and visual inspections for leaks or hose wear. Electric setups demand motor diagnostics, control box assessments, and occasional drivetrain servicing. A disciplined maintenance cycle reduces downtime and extends the service life of both the component and the truck chassis it anchors. The maintenance cadence should reflect the intensity of use. A fleet that cycles through a high volume of medium-weight loads every day will benefit from more frequent checks than a fleet used for lighter, sporadic shipments. Integrating maintenance reminders into the driver’s routine helps bridge the gap between depot service windows and the realities of back-to-back deliveries.

Third, the human element remains central. The most sophisticated lift gate can be undermined by inconsistent operation or poor load planning. Driver training is not a one-off event but a continuous discipline. Operators need clear guidance on weight limits, load distribution, and the specifics of safe maneuvering near pedestrians and other vehicles. When training is robust, the gate becomes a natural extension of careful handling practice rather than an afterthought. This training should also address emergency procedures, such as what to do if a gate stops unexpectedly, how to secure loads that shift during movement, and how to communicate with warehouse teams about anticipated dwell times. The combination of a reliable system, regular upkeep, and well-prepared operators creates a learning loop that sustains safety and productivity across the fleet’s life cycle.

The strategic value of lift gates shows up in the economics of delivery networks as well. When a shipper must choose between installing a lift gate on a vehicle or relying on dock availability or manual lifting, the calculus often favors the former in urban and regional networks. The improved safety profile reduces workers’ compensation exposure and the costs associated with manual handling injuries. The faster unload cycles translate into tighter delivery windows and higher daily throughput, which can lower per-stop costs and improve service levels in competitive markets. It is not merely about moving heavier items more quickly; it is about reducing the variability that can erode schedule reliability and degrade customer experience. In this light, lift gates become a component of a broader design philosophy for resilient logistics, where equipment choices align with workload profiles, site constraints, and the service expectations of customers who count on predictable delivery.

For those readers who want a practical touchstone, it is useful to think of the lift gate as a dependable partner in the flow of goods. In a world where many stops occur at locations without docks, the gate removes a persistent friction point. It provides a controlled transition from ground to vehicle deck, enabling safe accommodation of heavy, bulky, or awkward loads. It helps ensure that items arrive intact, clients receive consistent service, and drivers can operate with confidence rather than ad hoc improvisation. The technology itself is relatively straight-forward, but the benefits accrue from thoughtful configuration, careful maintenance, and disciplined operation that respects human safety and product integrity. In short, lift gates do more than move weight; they enable the rhythm of reliable delivery in environments that demand both scale and care.

For professionals who want to explore more about the configurations, safety considerations, and practical deployment guidelines for lift gates, the guide on lift gates offers a focused overview and practical insights that complement the experiences described here. lift gates.

As these stories suggest, industrial lift gates are not homogeneous in their design or application. They adapt to the specific cargo mix, site geography, and workflow patterns of a business. A fleet that serves both manufacturing lines and remote retail locations benefits from a flexible approach to choice and configuration, one that acknowledges the realities of both production scale and service constraints. The most successful implementations are those that treat the lift gate as a scalable component of the logistics engine—one that can be tuned as volumes grow, as routes evolve, or as environmental and safety standards shift. In this sense, lift gates contribute to a broader narrative of efficiency that blends mechanical capability with procedural discipline. They are not a single upgrade but a system-level capability that helps a business sustain high performance across a broad spectrum of operating contexts.

Looking ahead, the evolution of lift gates is likely to be shaped by two trends: enhanced safety intelligence and smarter maintenance scheduling. Advanced sensing, connectivity, and analytics can give fleets real-time visibility into load conditions, gate performance, and potential failure modes. Predictive maintenance can anticipate seal wear, hydraulic leakage, or motor drift before it disrupts service. As fleets grow more interconnected, lift gates can become proactive partners in route optimization, adjusting unloading sequences to minimize dwell time or coordinating with on-site staff to streamline handoffs. While the core function remains the same—reliably lifting cargo from ground to bed—these enhancements promise to push efficiency, safety, and reliability even higher across the industrial spectrum.

External reference: https://www.british-trucking.com/industry-news/truck-lift-gates-enhance-logistics-efficiency-in-manufacturing-and-construction/

Final thoughts

The integration of truck bed lift gates into your logistics operations represents a significant advancement in efficiency, safety, and cost-effectiveness. By understanding the hydraulic mechanisms, prioritizing safety features, evaluating the economic implications, and exploring applicable industrial scenarios, business owners can make informed decisions to optimize their cargo handling processes. In a world that demands swift and safe delivery solutions, truck bed lift gates are not just a feature; they are essential investments that enable businesses to thrive in a competitive landscape.