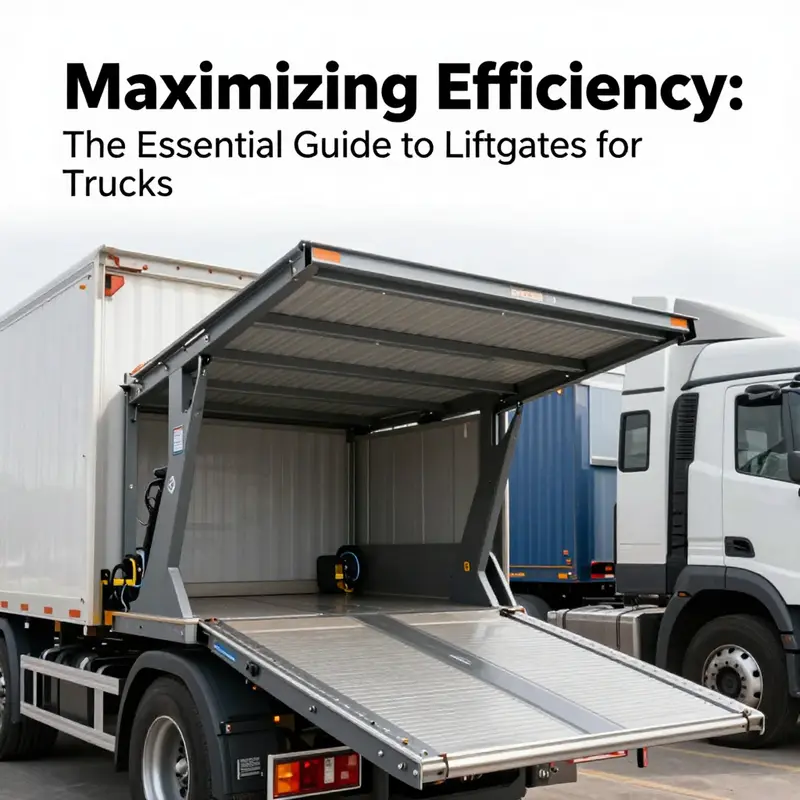

Liftgates for trucks are an integral tool for business owners looking to improve efficiency in loading and unloading operations. These specialized hydraulic and mechanical devices, installed at the rear of various truck types, offer significant advantages in moving heavy or bulky items with ease. As businesses adapt to increasingly demanding logistics requirements, understanding liftgate functionality, safety features, industry applications, and maintenance needs is crucial. This guide will delve into these aspects, equipping you with the knowledge to enhance your fleet’s capabilities and ensure safe operations.

null

null

Guarded Access: The Safety Features That Make Truck Liftgates Reliable

Liftgates are more than platforms; they are interfaces between ground and trailer that transform heavy, repetitive lifting into controlled, predictable motion. In busy loading yards and on job sites with uneven surfaces, the safety features woven into modern liftgates determine whether a day ends with a satisfied team and intact inventory or with avoidable injuries and delays. The design philosophy behind these systems centers not merely on lifting capacity or speed, but on an integrated approach that guards operators, bystanders, and the cargo itself. The result is a machine that behaves like a trained helper, obeying precise constraints and signaling clearly when something is amiss. In this light, safety is not an afterthought or a compliance checkbox; it is a core engineering objective that shapes every curve of the liftgate, every valve, every sensor, and every control handle.

Obstacle detection sits at the heart of the safety package. Sensors, whether pressure based, capacitive, or proximity oriented, scan the path of movement during both ascent and descent. The idea is simple in theory: if the system perceives an obstacle — be it a worker stepping into the platform’s arc, a stray pallet, or a stray tool left on the deck — it stops and, in many configurations, reverses. In some recent practice, the control logic escalates when three consecutive obstructions are detected within a single cycle, triggering an immediate halt to minimize risk and prevent a crush. These responses are paired with audible alerts that draw attention to the hazard zone, giving nearby personnel a clear cue to step back and reestablish a safe clearance. This triage of signals and responses helps create a shared work rhythm where operators learn to respect the boundary between the lift’s motion and the surrounding activity. The sensors remain vigilant even at the end of a shift when fatigue can dull ordinary perception, providing a last line of defense against overlooked risks.

Automatic closure with controlled descent reinforces the idea that safety is a continuous, monitored state rather than a momentary stop. Many liftgates incorporate hydraulic or pneumatic support systems that maintain the platform at any chosen height with fine-tuned stability. The moment power or hydraulic pressure wavers, these mechanisms engage to prevent a sudden drop. That means in the event of a power interruption or a pressure loss, the platform does not plummet. Instead, it descends slowly and safely, allowing the operator to regain control or to complete a controlled lower if an emergency release is required. This feature is crucial when handling heavy loads or working near uneven pavement, where a rapid, uncontrolled descent could translate into a missed grip, a rolled pallet, or a worker in the line of a potentially dangerous arc.

Manual override functionality serves as the human-in-the-loop safeguard when automatic systems need a hand. Even with the most robust electronic or hydraulic setup, there are moments when a technician or an operator must assume direct control to complete a safe operation. Hand cranks and mechanical releases provide that option, ensuring that cargo can still be unloaded or repositioned under adverse conditions or during routine maintenance. The presence of a reliable manual option communicates a practical philosophy: automation is paired with tangible fallback mechanisms that keep operations moving without forcing people to improvise under pressure. Properly designed manual overrides reduce downtime and limit the risk of attempting to improvise a workaround that could compromise safety.

Interlock systems extend the safety boundary beyond the liftgate itself by tying the gate’s status to the vehicle’s operational state. When the gate is not fully closed and secured, electronic sensors relay a signal to the vehicle’s dashboard or control module, often resulting in a demonstration of a lockout that prevents the truck from proceeding. In many implementations, a warning such as REAR ACCESS OPEN lights up on the instrument cluster, reminding the driver that the gate must be locked and stowed before the vehicle can be moved. This integration reduces the chance of a driver inadvertently driving away with the gate in an unsafe position, a scenario that can lead to structural damage, personal injury, or damage to surrounding equipment.

Beyond the core mechanisms, the safety ecosystem around liftgates includes a variety of passive and active measures designed to create a safer work zone. Visual cues such as safety cones, pylons, stanchions, and illuminated warning lights help delineate the operational footprint. In low-light conditions or high-traffic environments, truck flashers, strobe lights, or dedicated safety beacons can be activated to clearly mark the location of the liftgate and its moving range. These cues are not ornamental; they serve a practical purpose by guiding pedestrian traffic and signaling operators to maintain safe margins, which is essential when a liftgate is in motion and pallets weigh hundreds or thousands of pounds.

Another essential pillar is the adherence to training and procedural discipline. Knowledge alone does not guarantee safety; it must be reinforced through consistent practice. Operators should be trained to avoid standing under a raised platform, to ensure all load restraints are secured before lowering, and to confirm the gate is fully closed before driving. Maintenance logs should be kept, and any malfunctioning sensors, hydraulic leaks, or control glitches addressed promptly. A well-documented maintenance culture does more than protect workers; it extends the life of the equipment by ensuring that safety features operate within the designed tolerances. In environments where turnover is high or where multiple crews share a single vehicle, a clear, observable safety protocol becomes the glue that holds everyday work together, reducing the likelihood of human error compounding a risk point.

The regulatory frame surrounding liftgates reinforces this safety-first approach. The U.S. Department of Transportation and the Occupational Safety and Health Administration provide guidelines that emphasize hazard prevention, operator training, and equipment maintenance for material handling devices in transportation contexts. A central reference is the rule set that governs powered industrial trucks, including liftgates, and specifies how operators should be trained, how equipment should be maintained, and how hazard prevention should be integrated into daily workflow. While the details of compliance can vary with jurisdiction and specific equipment, the overarching mandate remains consistent: safety features must be tested, documented, and paired with competent human oversight. In practice, this means routine inspections, calibration of sensors and interlocks, verification of emergency stops, and periodic retraining that reflects changes in equipment or procedures. The goal is not to corner teams into rigid compliance but to ensure that every loading cycle proceeds with a built-in safety margin that respects the real-world variability of workplaces.

The human factors dimension of liftgate safety cannot be overstated. Even the most sophisticated safety hardware is only as effective as the people who operate and supervise it. Clear communication about expectations, a shared mental model of risk, and a routine that prioritizes zone control and awareness are as important as the mechanical interlocks. Teams benefit when supervisors reinforce safe behaviors and when workers are encouraged to pause and review the process for potential hazards before every lift. This approach reduces the probability of overconfidence after a string of efficient cycles and helps sustain a culture where safety is continuously demonstrated, not merely claimed. The practical upshot is a calmer, more predictable loading scene where the interplay between machine, operator, and bystander becomes a coordinated performance rather than a series of isolated actions.

The practical takeaway for managers and operators is straightforward: invest in safety features as you would in a critical infrastructure component. Select liftgates that offer robust obstacle detection, reliable automatic closure with controlled descent, dependable manual overrides, and integrated interlocks. Build a workspace around the equipment that supports clear visibility and predictable movement. Pair this with rigorous training, meticulous maintenance, and a culture that treats every lift as a potentially hazardous operation that deserves careful preparation. In doing so, the organization reduces the risk of costly injuries, protects the integrity of goods, and elevates overall productivity. For readers seeking practical guidance on liftgate systems and their broader context, a concise reference is available in the liftgates section of this site that delves into fundamentals and best practices. liftgates

The chapter’s synthesis is simple but powerful: safety features are the connective tissue that makes liftgates reliable in high-stakes environments. They translate the manufacturer’s engineering intent into actionable protections that keep people safe and cargo secure, even under the pressures of busy schedules, adverse weather, and variable ground conditions. When these features are designed with an explicit attention to human behavior, and when procedures reinforce rather than replace common sense, liftgates move from being mere attachments to becoming trusted teammates in the day’s workflow. The result is a safer, more efficient operation that can scale across fleets, sites, and job types without sacrificing the core value of safety that underpins every successful loading and unloading cycle.

External resource: For authoritative safety guidance on powered industrial trucks including liftgates, consult the OSHA guidelines at https://www.osha.gov/standards/29CFR1910.178. This standard provides comprehensive requirements for operator training, equipment maintenance, and hazard prevention that complement the on-the-ground practices described here.

null

null

From Ground to Grasp: The Essential Rhythm of Maintenance and Installation for Truck Liftgates

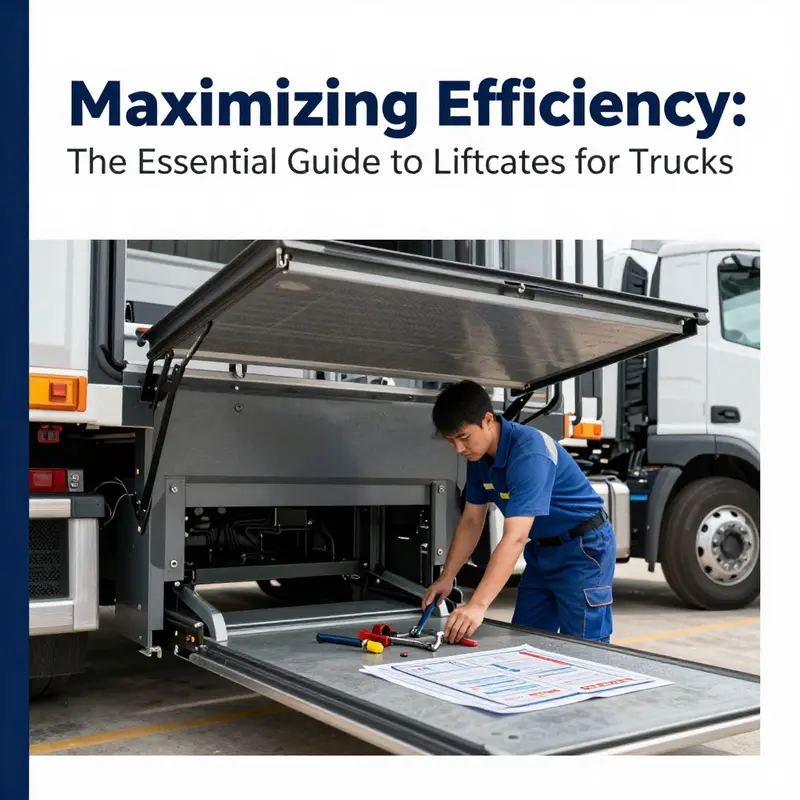

A liftgate is more than a mere accessory on a truck. It is a disciplined interface between the operator, the cargo, and the ground. When a fleet moves hundreds of miles each day, the chance that a heavy pallet or awkward irregularity will derail the workflow is real. The way a liftgate is installed and kept in good working order often determines whether a delivery deadline is met, and it can spell the difference between a safe, efficient operation and a costly safety incident. This is why maintenance and installation deserve more attention than they sometimes receive in the rush of daily dispatches. The liftgate functions as an elevated, load-bearing stage that translates the labor of loading into the predictable, controlled motion of hydraulic or mechanical systems. The operator relies on a trusted sequence: the platform lowers to ground level, the item is secured, the gate rises, and doors swing closed behind it all with a measured calm. When any part of that sequence falters, the consequences ripple through the operation: delays, worker fatigue, equipment wear, and the potential for injury. The objective of this chapter is not to overload readers with technical trivia but to weave maintenance and installation into the everyday narrative of truck work. It is to help managers, technicians, and operators see preventive care not as an imposition but as a core component of reliability and productivity. The maintenance mindset begins with the hydraulic and mechanical backbone of the liftgate. The hydraulic system, often the heart of the mechanism, depends on seals, hoses, cylinders, and reservoirs to deliver smooth, controlled movement. Leaks, worn hoses, or soft seals can manifest as jerky movement, reduced lift capacity, or slow return to ground level. A trained eye learns to spot the telltale signs: tiny damp spots along the frame, a faint whiff of hydraulic fluid near the mounting area, or a gradual loss of lift height under load. Regular inspection is more than a quick visual check; it is a structured practice that includes tracing hoses for nicks, inspecting fittings for corrosion, and verifying that the reservoir and lines remain free of insulation damage and exposure to the elements. Lubrication of moving parts—hinges, pivots, and guide rails—plays a quiet but critical role in longevity. Like any machine with metal-on-metal contact, the gate’s joints benefit from a light, targeted application of lubricant that does not attract dirt or debris. In a working environment, dirt and moisture are constant partners; a routine cleansing routine that removes grit and reduces exposure to corrosive substances can extend the life of components that are otherwise prone to wear. Electrical connections deserve particular attention. The control panel, wiring harnesses, and sensor circuits enable safe operation and precise control. Oxidation, loose connectors, or worn insulation can cause sporadic operation or intermittent fault signals that disrupt service. A robust maintenance plan includes cleaning, tightening where appropriate, and performing functional tests that verify that safety interlocks operate correctly. These interlocks prevent operation if the platform is not fully secured or if someone is present on the platform during movement, and they are the last line of defense against accidental injury. In practice, this means integrating regular checks into the routine of vehicle maintenance. A truck that follows a preventive schedule will often see fewer unscheduled repairs and less downtime. The schedule typically prescribes inspection intervals for hydraulic lines, cylinder seals, and electrical wiring, along with torque specifications for mounting bolts and fasteners. While exact intervals and torques vary by model and vehicle, the principle remains constant: predictable maintenance beats reactive fixes. A clean liftgate is a cue to operator vigilance as well. Debris that accumulates on the platform and around the hinges can obscure wear and wear patterns. Regular cleaning, including the underside of the platform and the rail tracks, reduces the risk of foreign objects jamming the mechanism or interfering with sensors. A practical takeaway is to treat the liftgate as part of the vehicle’s safety system. A clean, well-lubricated, and properly connected liftgate reflects good maintenance culture and signals to every member of the crew that safety is a shared value. The topic of maintenance cannot be separated from the installation process. The installation phase lays the foundation for safe operation and predictable service life. It begins with a rigorous assessment of the mounting frame and the vehicle’s structure. The frame must be capable of supporting the liftgate’s weight and the dynamic loads it will encounter during use. A professional installer verifies the vehicle’s chassis for any prior damage or stress and confirms that mounting brackets align precisely with the vehicle’s structure. Misalignment introduces uneven loading, which can accelerate wear and even compromise the integrity of the mounting points. Once the structural assessment is complete, precise alignment of the liftgate brackets becomes the next vital task. The alignment must be spot-on so that the platform remains level throughout its range of travel. Any tilt or side-to-side deviation imposes uneven stresses on the hinge assemblies and the mounting hardware, which over time may lead to fatigue or bolt loosening. Proper torqueing of bolts and fasteners is non-negotiable. The installation procedure specifies torque values that ensure fasteners stay snug under vibration and dynamic loads. Over- or under-torquing can create a cascade of problems, including bolt loosening, misalignment, and structural failure. The electrical side of installation must be protected from the onset. Cables should be routed cleanly, away from heat sources, and secured to prevent abrasion. As with maintenance, a careful installation includes testing that goes beyond a single lift and lower cycle. Operators should verify that control panels respond promptly, sensors detect platform position accurately, and emergency stop devices halt movement as intended. A comprehensive functional test is the culmination of good practice: it demonstrates to the crew that the system behaves within its design parameters and that safety features are active and reliable. The synergy between maintenance and installation becomes clear when considering the lifecycle of a liftgate. A well-installed liftgate is easier to maintain because its mounting points are predictable, its electrical paths are protected, and its moving parts have clean, accessible access. Conversely, a maintenance program that does not account for installation realities can miss upcoming issues, such as mounting fatigue or alignment drift, which can otherwise be caught early with a proper check. In practice, teams that treat installation as a one-off event and maintenance as a recurring nuisance fail to leverage the full return on investment that liftgates offer. The most successful fleets embed liftgate care into a broader maintenance culture. They keep thorough records of installation dates, bolt torque values, sensor calibrations, and preventive maintenance tasks. They establish a routine for debris removal and lubrication that reflects the environmental conditions in which the vehicle operates. These practices support predictable performance, reduce downtime, and increase the lifespan of the liftgate’s core components. For readers seeking a concise, fleet-wide perspective on liftgates and how they fit into daily operations, a dedicated overview of liftgates provides a practical starting point and can be accessed here: liftgates overview at the liftgates hub. By engaging with that resource, operators can connect the dots between installation best practices and ongoing maintenance cycles, ensuring that the liftgate remains a reliable partner rather than a source of unexpected maintenance demands. The link is designed to offer a straightforward path for readers who want to relate the theory of installation and maintenance to hands-on daily use on the road. The integration of sound installation and disciplined maintenance creates a durable, safe, and productive tool for moving goods. When teams coordinate these activities, the liftgate becomes part of a seamless workflow rather than a separate maintenance burden. It is the attention to alignment, the discipline of torque, the diligence of cleaning, and the responsibility toward safety interlocks that turn a liftgate into a trusted ally in the cargo-handling process. Across different vehicle configurations—service bodies, flatbeds, box trucks, and cargo vans—the same principles apply. The orients may vary, but the fundamentals of solid mounting, precise alignment, protected electrical pathways, and a habits-based maintenance schedule remain universal. This universality offers a path for fleets to standardize their approach, train technicians consistently, and build a library of best practices that can be adapted to multiple truck setups. The practical takeaway is clear: treat installation as the moment when reliability is built, and treat maintenance as the ongoing commitment that keeps that reliability intact. For the curious reader, a practical overview of liftgates across different truck configurations is available here: liftgates overview. External resources in the field provide deeper, model-specific guidance on maintenance, testing, and safety, including formal recommendations on safeguarding the operator and the vehicle during every cycle of use. For more detailed maintenance tips, see this external resource on railgate maintenance tips.

Final thoughts

Understanding liftgates for trucks is essential for any business owner looking to enhance operational efficiency, ensure safety, and adapt to the demands of various industries. By learning about their technical specifications, safety features, and applications, as well as proper maintenance procedures, you can optimize your logistics workflow effectively. Elevate your operations today by investing in quality liftgates that meet your business needs.