Box truck lift gates are integral to enhancing the efficiency of loading and unloading operations in modern logistics. As businesses evolve, the demand for reliable and effective loading solutions has grown, particularly in high-traffic environments and last-mile delivery scenarios. This article will delve into the fundamental aspects of box truck lift gates, detailing their key features, types, safety standards, and market trends. Understanding these elements will empower business owners to make informed decisions when integrating lift gates into their operations, thereby optimizing their logistics processes and enhancing overall productivity.

Raising Efficiency, Reducing Risk: The Core Features That Power Box Truck Lift Gates

A box truck lift gate is more than a mechanical platform attached to a truck’s tail. In modern distribution networks, it acts as a tactile translation between heavy goods and the one-step, one-person workflow that keeps deliveries moving. The best lift gates do not merely ride up and down; they channel power, safety, and performance into a single, reliable system that can transform how teams handle pallets, crates, and bulky merchandise. When viewed through the lens of daily operations, the features of these devices read like a concise blueprint for efficiency: hydraulic or electric power that offers smooth operation with minimal effort, a built-in ramp that bridges the gap between ground and platform, and a design that stands up to the weather, the wear of frequent use, and the unpredictability of a busy loading dock. Each element connects to a larger goal—reducing operator fatigue, accelerating loading cycles, and improving overall safety in environments that never sit still.

Hydraulic power has long been the backbone of lift gate operation, delivering a balance of speed, control, and quiet performance. The hydraulic system allows the platform to rise and lower with a one-touch expectation, translating heavy-load handling into a process that typically requires far less human force than traditional manual methods. In the real world, this means crews can move faster with fewer stops to reposition or adjust loads, cutting the physical strain associated with repetitive lifting by a substantial margin. The result is not merely a sharper bottom line; it is a tangible improvement in worker safety and fatigue management. When a driver reaches the tail of a route with back-to-back stops, the ability to lift a pallet in a controlled, predictable way becomes a quiet, reliable advantage that compounds across a shift.

While hydraulic systems are the common choice, some lift gates incorporate electric motors for specific use cases or to support emergency backup during power fluctuations. The distinction matters in practice: hydraulic systems tend to deliver smoother, more nuanced control across a wide range of weights, which is crucial when the load varies from palletized groceries to flat-packed equipment. Electric options, meanwhile, can offer simpler maintenance or quieter operation in certain environments. Across the field, the best performers blend the strengths of both approaches, ensuring the operator can move from pallet to pallet with consistent speed and confidence while maintaining a controlled, stable handling rhythm. In either configuration, the core value remains the same: a system that translates motorized force into predictable, repeatable motion, so drivers can concentrate on route planning, safety checks, and customer communications rather than wrestling with heavy loads.

Capacity is the practical limit that defines the job a lift gate can do. Standard models are designed to handle substantial weights, typically ranging from about 1,000 to 3,000 pounds (roughly 450 to 1,360 kilograms). In the field, those figures translate to a broad spectrum of loads—from bulk food cases and beverage pallets to industrial components and rolled textiles. Some specialized configurations for particular truck sizes, notably 26-foot box trucks, are capable of managing up to 1,500 kilograms, a threshold that aligns with many mid-sized freight needs. Understanding these figures in the context of daily operations means acknowledging the importance of proper weight distribution, platform dimensions, and ramp geometry. A lift gate that exceeds demand can add unnecessary cost and weight to a fleet, while one that underserves the job can become a bottleneck. The sweet spot lies in choosing a model that aligns with the typical payload, the most common cargo shapes, and the spatial realities of loading bays and street-level access.

Durability is not a luxury feature; it is a fundamental requirement for equipment that sits at the mercy of weather, road grime, and constant use. High-grade, corrosion-resistant materials ensure longevity even when doors are left open in damp or salty environments, or when equipment spends longer than ideal periods exposed to the elements. The preferred construction often centers on robust steel alloys that resist rust and wear while maintaining structural integrity under repetitive cycles. The long-term reliability of hinges, actuators, linkages, and the platform itself depends on this resilient design. A lift gate that remains sturdy after years on the road reduces maintenance downtime and maintenance costs, helping fleets stay on schedule. In practical terms, durability translates into fewer unexpected failures and a more predictable maintenance calendar—a quiet but critical factor in keeping supply chains resilient.

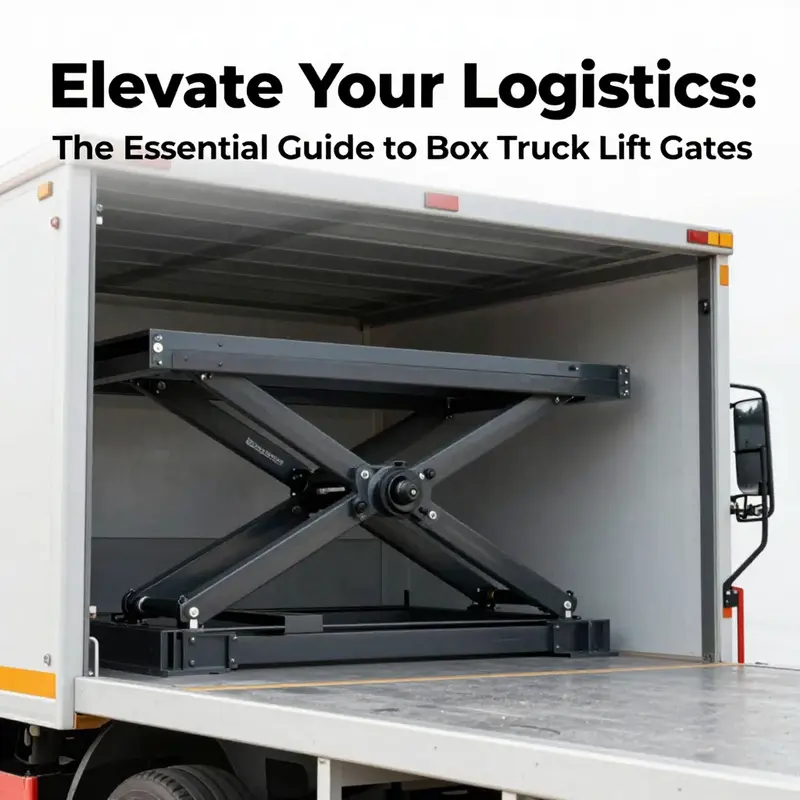

An integrated loading ramp is another defining feature with direct implications for speed and safety. A ramp lowers to ground level, creating a seamless pathway from ground to platform. This design reduces the number of handling steps a worker must perform, accelerating pallet placement and removal. In busy environments—where docks are crowded and pedestrian traffic is high—the ramp also lowers the risk of slips, trips, and minor injuries that can delay deliveries. The ramp’s geometry matters: a gentle incline, a stable track, and a widening platform edge that prevents pallets from tipping are essential details. When designed well, the ramp doesn’t just facilitate easier loading; it becomes a practical extension of the truck’s footprint, enabling faster, safer moves from street to shelf and back again.

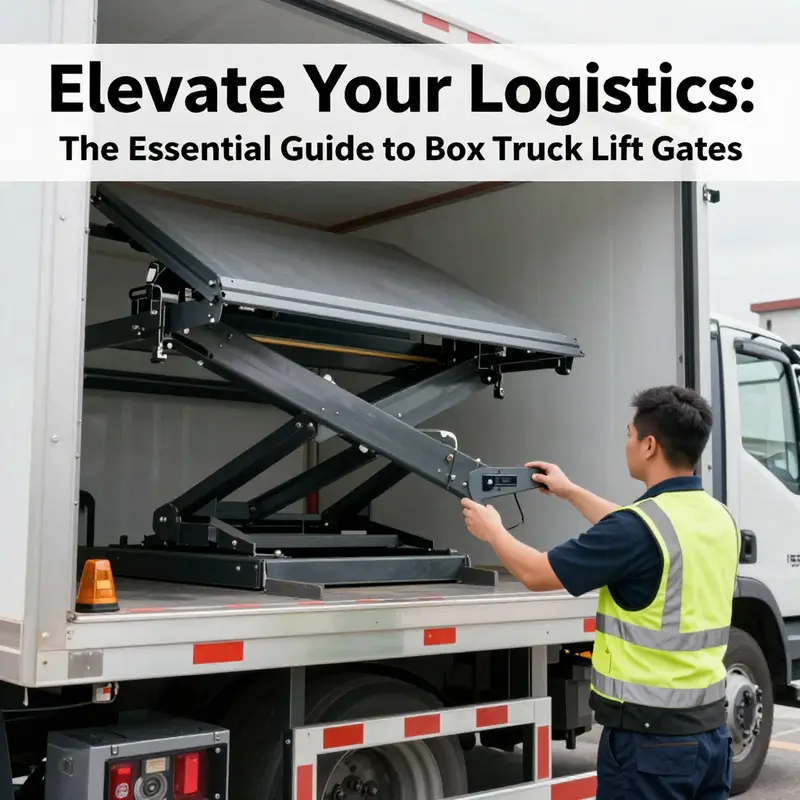

User-friendly controls are the human-facing side of the system. One-touch or similarly simplified controls empower operators to operate the lift with minimal cognitive load and reduced physical effort. In the field, such controls translate to fewer mistakes, quicker training, and more consistent performance across shifts. Clean layouts, clearly marked up-down indicators, and easy-access emergency stop features contribute to a sense of control even in crowded, high-pressure settings. The practical upshot is a workforce that spends more time delivering value—matching pallets to loading bays, verifying product integrity, and updating customers—rather than wrestling with complex machinery. When operators understand exactly how to operate the gate with a single click or press, the entire delivery process gains predictability and speed.

Safety compliance our of sight and beyond the operator’s hands is an essential throughline. Lift gates are often equipped with reflective strips, brake lights, and audible or visual warnings to enhance visibility for other road users and pedestrians. This is particularly important for fleets that operate at night, in busy urban centers, or along congested corridors where the risk of near-miss incidents is higher. Operational safety also extends to the gate’s return to rest and secure positioning. Proper immobilization during transit prevents unintended movement, protecting drivers, pedestrians, and nearby goods. In practice, these safety features do more than meet regulatory expectations; they create a culture of conscientious operation that reduces the risk of damage to cargo and vehicle alike and supports a smoother, more predictable loading routine.

Compatibility and design flexibility are what allow lift gates to fit into varied fleets and business models. Builders have long recognized that different truck sizes—such as 26-foot and 53-foot box configurations—require tailored platforms, mounting kits, and defensive shields. The best products are adaptable enough to pair with common door types, including swing or roll-up doors, and they accommodate optional features like integrated partitions or adjustable platforms. This adaptability matters increasingly in a logistics landscape that prizes modularity and customization without sacrificing reliability. In real terms, a lift gate that can be spec’d with an extended ramp, a narrowed frame for tighter yards, or a more generous platform surface is better suited to industries that routinely move heavy, bulky, or oddly shaped loads. It also means fleets can standardize on a relatively small family of gate systems across multiple vehicle types, simplifying maintenance and spare-parts logistics.

The broader value of lift gates, of course, emerges when you connect them to the realities of specific industries. In food and beverage distribution, quick, secure handling of temperature-sensitive goods becomes practical only when the platform remains steady and can be moved with one hand while the other protects perishables. In pharmaceutical and medical supply transport, minimal contamination risk and clean transfer surfaces are paramount, and a well-sealed platform that resists corrosion contributes to that objective. Retail and e-commerce logistics demand speed and reliability at last-mile touchpoints, where lift gates enable timely replenishment of store shelves or direct-to-consumer deliveries without dock access. Construction and heavy equipment transport require gates that can handle robust weights and withstand rough environments, where a sturdy ramp and reliable hydraulic system can prevent delays caused by equipment misplacement or loading difficulties. Across these contexts, lift gates translate engineering into practical, measurable gains: faster cycle times, safer handling of heavy goods, and a more predictable schedule that reduces the back-and-forth of backorder delays.

From a procurement perspective, the decision to invest in a lift gate should consider more than the sticker price. Suppliers’ engineering capability, quality control standards, and adherence to safety certifications can influence long-term performance well beyond initial purchase. A thoughtful procurement approach weighs the strength of the platform, the reliability of the hinge assemblies and linkages, and the consistency of the hydraulic or electric components under real-world use. Even the smallest components matter—seals, bushings, and wear plates can influence efficiency, noise, and the frequency of maintenance. A well-chosen system minimizes downtime and provides a clearer path to a fleet that stays on schedule, even when routes become congested or weather disrupts normal operations. In effect, the lift gate becomes a strategic asset rather than a simple piece of equipment, a decision that supports overall fleet reliability and service levels.

Regionally, there is a notable pattern in where lift gates are produced and how quickly fleets can access replacement parts or upgrades. Manufacturing hubs in major producer regions often emphasize vertically integrated capabilities. This means fewer handoffs between design, fabrication, and finishing, which translates into shorter lead times and more consistent quality. The combination of robust structural components, precise hydraulic frames, and tight quality control is what keeps lift gates performing reliably through the miles. For fleet operators, this can translate into lead times that fit within planned maintenance windows and replacement cycles that align with budget planning. It also supports the ongoing need to keep spare parts on hand and to schedule routine service without derailing daily delivery commitments. Procurement teams, therefore, should not only assess the upfront cost but also the total cost of ownership, including expected maintenance cycles, warranty coverage, and the supplier’s capacity to respond quickly to service needs across a fleet.

To knit these threads together, a disciplined approach to selecting and using box truck lift gates rests on three pillars: capability and durability, operational fit, and supplier reliability. Capability and durability ensure the gate can bear the load and survive the environment in which a fleet operates. Operational fit means the gate integrates with existing truck platforms, door styles, and loading workflows. Supplier reliability brings in the assurance that spare parts, service, and ongoing engineering support will be available as the fleet scales or shifts toward different cargo profiles. When these elements align, lift gates become a steady backbone for multi-stop routes, enabling drivers to perform one of the most physically demanding tasks with greater ease and less risk. This, in turn, accelerates throughput across the supply chain, improves on-time performance, and supports safer, more efficient last-mile delivery.

For readers seeking deeper technical or procurement context, a concise overview of practical considerations and model variations is available on our site under the liftgates topic. For more context on liftgates, see liftgates.

External resources can also illuminate the broader landscape of equipment design, standards, and supplier options. A detailed supplier reference is available here: https://www.alibaba.com/product-detail/Hydraulic-Tailgate-Lift-26-ft-Truck-Lift-Gate_1600489532582.html?spm=a2700.190358.0.0

Lifting the Load: A Deep Dive into Box Truck Lift Gates, Their Types, and Real-World Impact

Box truck lift gates are not just a feature at the back of a truck; they are a critical bridge between cargo and delivery reality. When fleets move through the daily rhythm of last-mile routes, the ability to raise, lower, and position heavy goods with minimal effort becomes a measurable driver of speed, safety, and overall uptime. This chapter traces the different lift gate configurations that today populate the rear of box trucks, explains how each type aligns with specific cargo profiles and operating contexts, and connects these technical choices to the practical realities faced by drivers, warehouse teams, and customers alike. The aim is to illuminate how lift gates, in their various forms, translate into smoother throughput, fewer injuries, and more reliable service, whether a driver is delivering to a high-traffic urban corridor or serving a remote facility without dock access.

At the core of any lift gate decision is the balance between load capacity, control, and the environment in which the equipment will operate. Hydraulic lift gates remain the most common choice for high-frequency use, especially in fleets that routinely handle heavy pallets, bulky furniture, or sizable machinery. The hydraulic system uses fluid pressure to lift and lower a platform with gentle yet powerful motion, allowing a single operator to manage tasks that would otherwise require multiple people or a dock with ramps. The appeal is clear: a smooth, controlled lift that reduces strain and fatigue. In practice, this translates to faster unload times, fewer back injuries, and a lower risk profile for operations that repeatedly hoist dense loads at the end of a route. For operations that see frequent door traffic or work in congested streets, the predictability of hydraulic action is a valuable asset, as the system responds promptly to switching conditions and can keep pace with the tempo of urban deliveries.

Electric lift gates provide a quieter, cleaner alternative that aligns with fleets seeking lower maintenance footprints and reduced hydraulic fluid risk. An electric motor powers the lift, eliminating some fluid-related leak concerns and the potential for hydraulic hose failures. The result is a system that often delivers smoother maintenance cycles and quieter operation—benefits that matter when a vehicle returns to service in environments where noise and spill risk must be minimized. Electric lift gates are particularly well suited to cutaway or forward-controlled box trucks, where the platform needs to integrate neatly with a compact cargo bay or where fleet managers want to simplify control architecture for technicians and drivers alike. Their precision control lends itself to delicate handling, a feature that becomes critical when transporting temperature-sensitive products or fragile equipment. The quiet, clean operation also appeals to fleets that value minimal disruption to customers and passersby in residential or light-commercial zones.

Manual lift gates occupy a smaller corner of the market today, yet they persist in some niche applications. In fleets that prioritize low upfront cost and have lighter average loads, manual systems can still offer a straightforward, low-tech solution. A hand crank or lever mechanism provides the operator with direct, tactile feedback during each lift, which some technicians find reassuring in off-grid environments. However, as cargo weight and frequency of use rise, manual gates quickly reveal their limitations: more physical labor, slower cycle times, and increased fatigue that can erode both safety margins and delivery consistency. For many professional operations, manual options are most defensible in light-duty turnover or as a temporary solution during fleet refurbishments, rather than as a core asset for ongoing, heavy-duty logistics.

Beyond these core categories, a subset of lift gates integrates a ramp that unfolds as the platform descends. The combination of gate and ramp creates a continuous pathway from ground level to the truck bed, which can be a game changer for versatile handling. Integrated ramps permit wheelchairs, dollies, and pallet jacks to roll directly onto the platform, reducing the number of hand-offs required and cutting the risk of slips, trips, and falls. In healthcare logistics or pharmaceutical distribution, where speed and contamination control matter, such integration supports efficient loading while maintaining strict handling protocols. In retail or e-commerce contexts, an integrated ramp helps staff move mixed freight quickly from curb to cargo, a benefit when dock access is scarce or when deliveries arrive during peak periods when every minute counts.

The payload envelope of lift gates varies widely, but a practical rule of thumb centers on typical commercial use: most systems are designed to manage loads in the 1,000 to 3,000 pound range. The ability to handle heavier stock—computers, appliances, bulk retail inventories, or bulky machinery—depends on platform size, hydraulic or electric power margins, and the structural integrity of the mounting assembly on the truck. When selecting a lift gate, fleet managers examine not only the maximum rated capacity but also the duty cycle—the number of lifts a gate can execute in a given period without overheating or requiring a cooldown. In high-frequency environments, well-engineered gates maintain performance under repeated cycles, while lower-grade units may exhibit slower response, reduced ramp credibility, or longer recovery times after each cycle. The design philosophy behind these choices reflects a broader principle: the equipment must harmonize with the truck’s chassis, the cargo profile, and the crew’s workflow so that loading operations stay resilient across a typical workday.

Material choice also plays a decisive role. Corrosion-resistant construction matters when vehicles park in varied weather, exterior exposure zones, or salt-prone environments. Many lift gates rely on high-strength steel framed in corrosion-resistant alloys or protective coatings, ensuring that moving components such as hinges, actuators, and linkages retain strength and precision over years of service. The alloy selection and protective finishes contribute to a longer service life, predictable maintenance schedules, and reduced replacement costs. In addition, the platform surface itself is designed to grip cargo, resist scuffing, and withstand temperature fluctuations that are common in food, beverage, or pharmaceutical handling. The physical robustness of the gate sits at the intersection of safety and reliability, a zone where the consequences of failure are measured in both downtime and potential injuries.

Safety features have grown into a standard language for lift gates. Reflective strips and brake lights are not mere add-ons; they are visible warnings that alert other road users during gate operation, especially in late-evening or early-morning deliveries. Emergency stop mechanisms, overload protection, and interlock systems ensure that an operator cannot overextend the platform or attempt to move while a load is shifting. In practice, these features translate into fewer incidents on the road and in loading zones, and they contribute to compliance with road safety regulations that govern commercial fleets. Some gates include audible warnings for nearby workers, further reducing the chance of accidental contact with the platform during operation. For drivers, clear signals and reliable safety interlocks become second nature, helping to maintain a calm, controlled pace through stressful delivery windows.

Compatibility remains a critical dimension of choice. Box trucks come in several standard configurations, including 26-foot, 40-foot, and 53-foot box lengths, with varying chassis designs such as cutaway, cab-forward, or rear-engine layouts. A gate that fits a 26-foot truck may not be ideal for a 53-foot trailer without appropriate mounting hardware or frame reinforcement. This complexity makes early, thorough specification essential: a door-to-door solution must accommodate the truck’s footprint, clearance, and ramp geometry while preserving ground clearance and stability. Some operators weigh the benefits of added features such as adjustable platforms, which permit variable loading heights, or integrated walk-through partitions that isolate the cargo area from the vehicle’s mechanical spaces while maintaining access to the rear gate for loading and unloading. These design flexibilities empower fleets to tailor lift gates to their most common cargo mixes and route patterns, minimizing the need for bespoke builds and accelerating fleet deployment.

From a procurement perspective, the decision-making process extends beyond the gate itself. Evaluating suppliers on engineering capability, quality control practices, and compliance with safety certifications is as important as the gate’s nominal load rating. A robust supplier relationship can translate into predictable lead times, consistent part availability for maintenance and repair, and better post-installation support when field service becomes necessary. In some cases, suppliers based in major manufacturing hubs deliver advantages in terms of fabrication precision and total cost of ownership. Regions known for structural components, hydraulic frames, and precision machined parts often provide both the hardware and the know-how to keep lift gates aligned with evolving safety standards and performance expectations. This integrated capability—engineering, manufacturing, and QC under one roof—helps fleets avoid the friction that arises when components from different vendors must be synchronized and tested together. It also creates a pathway for fleets to upgrade or reconfigure lift gates as cargo profiles shift, rather than facing a full gate replacement.

Operationally, lift gates influence the daily rhythm of a fleet. For distribution centers, the presence of a dependable rear lift gate reduces dock dependence and expands the window for delivering to stores and customers without requiring traditional loading docks. For last-mile crews, a gate that operates with minimal effort translates into faster turn times, reducing the time spent in loading zones where congestion can stall an entire schedule. For maintenance teams, the reliability of a gate correlates with uptime and vehicle availability, which in turn affects route planning and customer service levels. Across industries—whether food and beverage distribution, health care and pharmaceuticals, or retail and e commerce logistics—the lift gate is the quiet workhorse that makes complex scheduling feasible. It is the element that often goes unnoticed until it fails or underperforms, at which point the impact is immediate and felt across the supply chain.

To ground these considerations in a concrete picture, imagine a typical scenario: a 53-foot box truck arrives at a residential area to deliver large furniture pieces. The driver deploys the hydraulic lift gate, which rises smoothly to the pallet height. A helper wheels a dolly onto the platform, secures the load, and signals the truck to reverse into a driveway while the gate maintains a controlled ascent. The ramp, if integrated, unfolds in a seamless extension, enabling the dolly to glide into a living space with minimal pushing effort. The entire operation, from arrival to offloading, unfolds with a rhythm that keeps traffic on the street moving and reduces the risk of back strain or dropped pallets. In a pharmaceutical delivery, the same gate configuration might be paired with an integrated ramp and a highly controlled lift cycle, ensuring that temperature-sensitive units are handled with contamination control and precise positioning at loading docks or patient care centers. The point is simple: the type of lift gate you choose shapes not only the hardware in your fleet but the tempo and safety of every delivery.

For readers seeking a practical entry point to this topic, our dedicated guide on liftgates offers a concise overview of options, including the trade-offs between hydraulic and electric systems and the scenarios in which an integrated ramp provides the most value. This resource helps fleet managers translate the technical specifications into actionable procurement decisions and return-to-work outcomes. liftgates

Beyond the internal considerations, the global context of lift gate production influences availability, cost, and lead times. Leading suppliers—especially those embedded in manufacturing hubs with vertically integrated capabilities—offer the advantage of coordinated fabrication of structural frames, hydraulic components, and actuation systems. Regions that specialize in robust structural components and precision parts often deliver cost efficiencies, shorter lead times, and the flexibility to support low minimum order quantities for fleet maintenance and repair needs. When evaluating suppliers, it is valuable to look beyond price and delivery speed. Strong engineering capability, rigorous quality control, and robust safety certifications lay the foundation for a lift gate that endures through many cycles of use in varied weather and traffic conditions. As with any critical fleet component, the long view matters: correct installation, consistent maintenance, and timely parts replacement determine whether a lift gate remains a reliable partner through seasons of peak demand.

For those who want to review external sources to calibrate expectations about performance and specifications, one broadly cited source offers detailed technical parameters and real-world performance insights for hydraulic tailgate lifts designed for mid-size box trucks. This reference provides a data-backed sense of what a well-engineered gate can achieve in terms of payload, recovery behavior, and lifecycle expectations. External link: https://www.alibaba.com/product-detail/Hydraulic-Tailgate-Lift-26-ft-Truck-Lift_1600548933529.html?spm=a2700.189961.0.0.7a8f1c1dNnFtZU. The information there helps buyers compare typical gate features, though it should be considered alongside supplier-specific certifications, warranty terms, and on-vehicle compatibility checks performed during procurement.

In sum, the choice among hydraulic, electric, manual, and integrated ramp lift gates is a decision about how a fleet wants to balance speed, safety, and reliability in real-world operations. Each type has a story—one of how a gate’s motion, control precision, and integration with the truck chassis determine the ease with which goods move from ground to cargo and back again. When fleets align their lift gate selection with the typical cargo profile, route density, and dock access realities they face, they unlock a form of operational leverage that resonates through every link in the delivery chain. The lift gate becomes less a piece of hardware and more a strategic enabler of performance, safety, and customer satisfaction, quietly extending the reach of the fleet while keeping the driver’s job safer and more efficient.

Guardrails on the Ground: Safety Standards for Box Truck Lift Gates

Box trucks enable dockless loading via lift gates, but safety standards shape every aspect of their design, use, and upkeep. This chapter outlines the core requirements that influence visibility, structural integrity, and operator safety, showing how standards become practical guardrails that reduce risk in real world loading scenarios.

At the center of lift gate safety is visibility. Requirements call for clear signaling that a device is present and in use: reflective markings, rear and brake lighting integrated with the gate, and unambiguous control indicators. In busy yards, these cues help drivers, pedestrians, and forklift operators anticipate movement and avoid contact.

Structural integrity and load capacity are the other core pillars. Lift gates are designed with a safe working range that commonly spans about 1,000 to 3,000 pounds, depending on platform size and duty cycle. A realistic margin for dynamic loads, uneven ground, and misalignment is essential to prevent overload and ensure stable operation.

Operational safety features bridge strength and safe use. One touch controls simplify the user interface, while sensors detect obstructions on the ramp or near the platform and stop or reverse motion as needed. A stable, non slip platform with secure mounting, locking mechanisms, and precise actuation reduces shifts during the transfer of goods.

Compliance with road safety regulations is the umbrella for lift gate features. Manufacturers must validate that the gate installation meets roadworthy standards and that labeling and documentation support inspections. Operators should follow safe loading procedures and keep reflective elements visible in normal conditions.

Maintenance and inspection cadence translate standards into daily discipline. Daily visual checks for leaks or abnormal noise, weekly functional tests, and monthly or quarterly inspections of lighting, reflectors, and platform stability create a safety culture. Regular lubrication of hinges and rails prevents binding and erratic movement.

Training and competency development are inseparable from safety outcomes. Operators should learn the step by step loading sequence, how sensors respond to obstructions, and how to recognize hazardous conditions around the ramp. Clear signage and ongoing coaching reinforce safe habits across shifts.

Retrofits and upgrades require regulatory compatibility and clear documentation. Upgrading sensors, lighting, or platform stability should be planned with supplier guidance, validated test results, and retraining to maintain a consistent safety profile. Documentation supports audits and ongoing risk management.

For readers seeking practical guidance, many manufacturers provide resources that distill lift gate design, operation, and safety into approachable checklists and best practices. A well organized procurement process maps expected loads, duty cycles, and climatic conditions to feature sets that balance safety and total cost of ownership. The core message is that safety standards enable reliable, predictable loading operations rather than hinder productivity.

Raising Efficiency Across the Dockless Era: The Transformative Role of Box Truck Lift Gates in Modern Logistics

A lift gate at the rear of a box truck is more than a mechanical appendage. It is a quiet revolution that extends the truck’s reach from the warehouse dock to the curb, the loading dock at a shopping center, and the slippery loading zone in a bustling alley. When the hydraulics rise with a patient, predictable hum and the platform settles level with the ground, the driver, the helper, and even the goods experience a shift in rhythm. What once required back-breaking effort, risky maneuvering, and complex planning becomes a one-button sequence: engage, lift, slide, and secure. This transformation is not just about convenience. It is a core efficiency lever in contemporary logistics, one that aligns with the relentless push toward faster deliveries, safer handling, and more predictable throughput. The box truck lift gate sits at the intersection of mechanical reliability, intelligent safety, and fleet-operational strategy, and its evolution mirrors broader shifts in how goods move through urban and regional networks.

The heart of the lift gate story is hydraulic power. Across the industry, hydraulic lift systems have become the standard for smooth, controlled operation. They provide a balance of force, precision, and reliability that outpaces older pneumatic or purely manual systems. A one-touch lift that can raise a payload without the operator straining shoulders or compromising footing translates into measurable gains: faster loading cycles, fewer injuries, and more consistent handling of diverse cargo—ranging from dense pallets of beverages to sensitive equipment and flat-packed retail stock. When a driver can trust that the gate will respond predictably to a single command, the sequence of loading and unloading becomes an arithmetic of time saved rather than a series of improvisations. In practical terms, the stately ascent and descent of the platform reduce physical exertion by a broad margin—often cited as up to seventy percent—but more important is the predictability. Reliability converts potential bottlenecks into smooth operations, especially in high-traffic delivery environments where every second counts.

Alongside hydraulic power, modern lift gates feature high load capacity designed for demanding use. In many fleets, 1,500 kilograms (about 3,300 pounds) is a common threshold, a boundary that covers the majority of heavy consumer goods, bulk grocery loads, and intermediate industrial shipments. The capacity is not just about lifting weight; it is about leaving headroom for secure stacking, stabilizing loads during transit, and accommodating variations in pallet sizes and strap configurations. Operators exchange rough handling for controlled, repeatable movements, and the result is a gentler, safer transition of goods from ground level to vehicle deck. This capability is especially vital in industries where goods can be bulky, irregularly shaped, or temperature-controlled. A lift gate must not merely hoist; it must cradle the cargo in a way that preserves integrity while reducing the risk of shifting during transit.

Materials matter, too. The most durable lift gates rely on corrosion-resistant construction and robust frames. High-strength steel alloys—often described in industry literature as equivalents to Q700-grade steel in structural components—provide the backbone for a long service life in outdoor settings. The platform and supporting arms are engineered to withstand repeated cycles, temperature swings, and exposure to road grime, moisture, and road salt. The result is a system capable of sustaining heavy workloads across years of operation with minimal performance drift. Corrosion resistance translates into lower maintenance costs and fewer unplanned downtime events, both of which are vital in fleets that run close to capacity on tight delivery windows. In practice, that means less grease, fewer bolt replacements, and reduced risk of platform fatigue that could compromise safety or require costly downtime.

No discussion of lift gates would be complete without addressing safety. Integrated safety features are a must, not an afterthought. Reflective strips and brake lights are standard components, improving visibility for drivers on the road, particularly when a lift gate is deployed on busy urban streets at dusk or in wet conditions. Warning systems, audible alarms, and interlock mechanisms contribute to a safer loading process, ensuring that the platform is stable before a pallet is moved or a ramp is engaged. The safety logic extends into design: hinge arrangements, actuators, and linkages are engineered for both smooth operation and fault tolerance. For fleets that must meet rigorous regulatory standards, these elements are not negotiable; they are the minimum required to protect workers and to maintain compliance across inspections, audits, and insurance requirements.

The scalability of lift gates is visible in the design flexibility offered to customers. A broad spectrum of configurations exists to fit different truck footprints—whether a 26-foot box truck or a longer 53-foot trailer. Custom features like integrated loading ramps, walk-through partitions, and adjustable platforms enable fleets to tailor a solution to their specific workflow. A ramp that folds neatly into the platform, for instance, can save space in crowded loading zones and reduce the risk of trips and falls. Adjustable platforms allow operators to optimize for pallet heights and varying cargo dimensions, a convenience that translates directly into faster cycles and fewer awkward handlings. In essence, the lifting system becomes part of a bigger logistics architecture rather than a standalone tool; it aligns with vehicle design and warehouse procedures to harmonize loading and unloading sequences across multiple touchpoints.

The practical benefits extend beyond individual operations to the fleet or enterprise level. For food and beverage distribution, lift gates facilitate quick, secure handling of temperature-sensitive goods, enabling rapid offload and minimizing exposure to ambient conditions. In pharmaceutical and medical supply transport, the precision and reliability of a hydraulic system contribute to contamination controls and careful handling of sensitive products. Retail and e-commerce logistics rely on lift gates to support last-mile efficiency, smoothing curbside and dockless deliveries where access is unpredictable. Construction and heavy equipment transport require ruggedness and high load tolerance, with lift gates that can handle bulkier, denser loads and withstand challenging outdoor environments. Across these use cases, the lift gate is a throughput accelerator, reducing manual labor while elevating safety standards—an investment whose return manifests in faster deliveries, lower injury rates, and improved customer satisfaction.

From a procurement perspective, the market presents a complex ecosystem that blends domestic manufacturing prowess with global sourcing dynamics. In major manufacturing belts within a country’s industrial hubs, we see a vertically integrated approach that minimizes lead times and controls costs. Regions with established clusters for structural components, hydraulic frames, and precision parts can deliver robust products with relatively short lead times. For fleets that operate across different geographies, this translated into an ability to standardize certain core components while still providing modular customization for regional needs. The emphasis on engineering capability, quality control, and safety certifications has become as important as the capacity and price tag itself. Buyers increasingly seek suppliers who can demonstrate a full-spectrum capability: from raw material sourcing and stamping to CNC processing, assembly, and post-production testing. Such vertical depth reduces risk and fosters long-term reliability for critical safety components such as hinges, actuators, and linkages.

A telling dimension of the market is the global sourcing landscape, which often centers on online platforms that connect buyers with vetted manufacturers. Catalogs and marketplace pages frequently feature a range of lift gate options tailored to different truck models and cargo profiles, with standardized safety features baked into the product design. The advantage of these platforms is not merely access to product pages; they provide a pathway to verification, customization quotes, and direct communication with engineers who can translate a fleet’s operational realities into technical specifications. For a fleet manager evaluating options, the decision often comes down to a blend of performance, total cost of ownership, and service ecosystem. The hydraulic system may be robust, the steel may resist corrosion, and the safety features may be comprehensive, but without dependable service networks for maintenance, calibration, and spare parts, even the best lift gate can become a liability during peak seasons or in remote locations.

In this context, the procurement strategy shifts toward partners with a strong engineering backbone and a track record of compliance with safety certifications. It is not just about meeting a single standard; it is about building confidence that a lift gate will retain its performance in harsh weather, endure thousands of lift cycles, and adapt to evolving regulatory requirements. A prudent buyer also looks for compatibility with a fleet’s broader maintenance program, including service intervals for actuators, lubrication schedules for moving joints, and inspection checklists that can be integrated into existing safety programs. Small details matter here: the reliability of hinges, the longevity of the hydraulic seals, the responsiveness of the electrical control system, and the robustness of the wiring harnesses against vibration and moisture. When these elements align, a lift gate becomes a strategic asset rather than a disposable component.

The chapter’s market narrative is not complete without acknowledging the global supply ecosystem that underpins these capabilities. In many cases, the leading suppliers operate within tightly knit regional ecosystems. In certain regions, proximity to raw material suppliers reduces costs and shortens lead times; in others, intense specialization in machining and precision assembly accelerates production cycles. The result is a layered, resilient supply chain, capable of absorbing fluctuations in demand and weathering the volatility that sometimes accompanies international trade. For buyers, this means that a well-chosen supplier can offer more than a product; they provide a pathway to continuous improvement in loading operations, maintenance planning, and overall fleet reliability.

As a practical takeaway for readers and practitioners, the emphasis should be on evaluating suppliers not only on one-off delivery speed but on engineering capability, quality control standards, and the capacity to meet ongoing safety certifications. The best partnerships are those that can demonstrate end-to-end support—from design iterations that tailor a lift gate to a fleet’s unique loading profile, to post-installation service that ensures uptime, to access to retrofits or upgrades as cargo mixes shift with seasons or markets. The result is a lifecycle approach: a lift gate that remains reliable across years of service, a technology partner that grows with a fleet’s needs, and a procurement stance that reduces risk while maximizing throughput. In this broader context, the lift gate is not simply a tool; it is an integral layer of a modern, resilient, and efficient logistics system.

For those who want to see how this market dialog translates into real-world options, catalogs and marketplaces offer a window into current capabilities. A representative listing for a 26-foot box truck features a hydraulic drive, a one-key control interface, corrosion-resistant steel, and a platform designed to support typical commercial loads. The product short list in these catalogs often highlights safety compliance with road-use standards and integration-ready interfaces for vehicle electronics, along with flexible service terms and minimum order quantities that accommodate fleet maintenance programs. The narrative across these pages is consistent: lift gates deliver measurable gains in efficiency and safety, supported by a mature engineering and manufacturing base that has learned to balance weight, strength, and precision with cost and availability.

Within this landscape, the internal knowledge base and practitioner communities increasingly emphasize practical guidance for procurement and deployment. Fleet managers who adopt a holistic approach—one that considers the lift gate as part of a broader loading workflow—tend to realize the most durable gains. They recognize that the value proposition extends beyond raw lifting power. It encompasses reduced manual handling, improved dock safety, better load stability during transport, and the ability to operate in environments without traditional loading docks. In busy urban centers, where dock access can be unpredictable and space is at a premium, the lift gate becomes a critical enabler of reliable service levels. The integration story—how a lift gate harmonizes with ramps, partitions, and vehicle electronics—reflects a mature product category that has evolved to meet the diverse demands of today’s fleets.

For readers seeking a concrete touchpoint in the industry, practical references often point to supplier catalogs that showcase the range of capacities, materials, and configurations. These sources illustrate how a 1,500 kg lift gate can be configured with optional ramps, anti-corrosion treatments, and load-sensing controls that minimize drive-by loads and maximize operator safety. They also demonstrate how safety features like reflective surfaces and signaling lights are embedded into the system to meet regulatory expectations while preserving operational fluidity. The net effect is a product ecosystem that supports a fleet’s need to deliver more with less effort, while also maintaining a high standard of safety and regulatory compliance across varied routes and cargo profiles. In this sense, the lift gate becomes a strategic asset that helps transportation teams push further into the dockless logistics paradigm without sacrificing reliability or safety.

To anchor the discussion in a broader market reality, consider the role of digital procurement platforms that connect buyers with vetted manufacturers and enable cross-border sourcing. A representative listing for a hydraulic tailgate lift highlights a payload capacity around 1,500 kilograms, a hydraulic drive system, corrosion-resistant steel construction, and compliance with European road-safety norms. These features, while technically straightforward, reflect a market that rewards integrated design thinking—where hydraulics, mechanical joints, and vehicle integration are treated as a coordinated system rather than isolated components. The growth of such platforms also accelerates the diffusion of best practices in installation, maintenance, and operator training, helping fleets move from piecemeal upgrades to cohesive loading ecosystems. In this context, the lift gate is a catalyst for longer-term efficiency gains, enabling fleets to retire older, less capable equipment and adopt upgrades that can be phased in with minimal disruption to ongoing operations. The resulting improvements—fewer incidents, faster turn times, and greater predictability—contribute to a safer, more resilient logistics chain.

In closing this contemporary portrait, the lift gate stands as a practical yet transformative technology. It embodies the convergence of robust mechanical design, intelligent safety, and strategic procurement that modern fleets require. The sector’s trajectory—toward electrification, smarter controls, and greater customization—promises to extend these advantages even further. What begins as a platform for loading and unloading heavy cargo becomes a core enabler of rapid, reliable service in a world where speed, safety, and sustainability increasingly define competitive advantage. The quiet, confident rise of the platform is a reminder that in logistics, the simplest tools often yield the biggest returns when they are engineered with a clear understanding of how goods move, how people work, and how the road shapes the journey from warehouse to customer.

For readers who want to explore a practical, ongoing reference point in this landscape, the liftgate is well-represented in industry catalogs and online marketplaces. These resources provide engineering details, safety certifications, and customization options that help fleets tailor a solution to their exact needs. As the market continues to evolve, buyers will increasingly prioritize suppliers who demonstrate end-to-end capability—from design and manufacturing through installation and after-sales service—ensuring that lift gates remain reliable partners in efficient, safe, and sustainable logistics across the long haul and the last mile. In that sense, the future of the box truck lift gate is not merely brighter; it is more precisely aligned with the intelligent, green, and accelerated logistics systems that define modern commerce.

For further context on current market behavior and supplier ecosystems, see the external resource linked below. The discussion in market analysis and supplier profiles can be complemented by practical examples and current product parameters found on major supplier platforms.

External resource: https://www.alibaba.com/product-detail/Hydraulic-Tailgate-Lift-26-ft-Box-Truck_1600549253767.html?spm=a2700.161017.0.0

Internal reference for practitioners: liftgates

Final thoughts

Box truck lift gates have emerged as vital components in optimizing loading and unloading operations across various industries. Recognizing their key features, understanding the types available, adhering to safety standards, and keeping abreast of market trends can enhance operational efficiency and safety. As you explore potential suppliers, prioritize those who demonstrate quality and reliability to ensure your lift gates support your business goals effectively. By investing in the right lift gate solutions, you can streamline your logistics processes and enhance productivity in your operations.