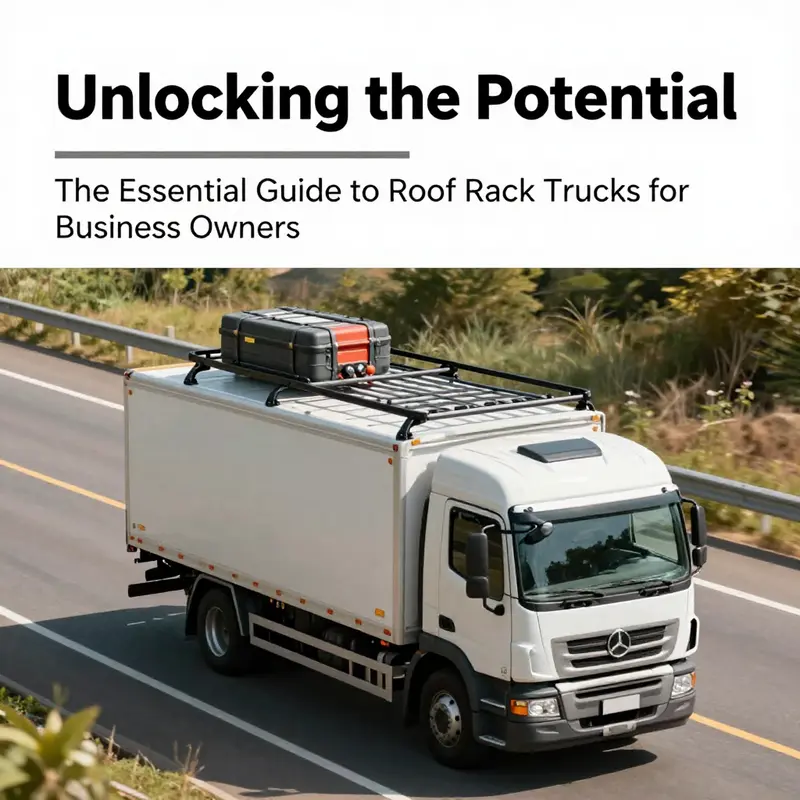

In today’s competitive business landscape, effective logistics and efficient transport solutions are crucial for success. For business owners relying on trucks, roof racks have emerged as indispensable accessories that enhance cargo capacity, enabling the safe transportation of tools, equipment, and leisure gear. This guide delves into different types of roof rack trucks, their materials and design considerations, and their vast applications in industrial sectors. By understanding these facets, business owners can make informed decisions that not only streamline operations but also bolster productivity. Each chapter of this guide aims to elucidate the particulars of roof rack trucks, their benefits, and the latest market trends and innovations, ultimately guiding you in choosing the right solution tailored to your business needs.

Choosing the Right Roof Rack for Your Truck: A Practical Guide to Types, Features, and Everyday Benefits

A pickup or a mid-size truck is more than a means of transport; it is a platform for expanding what you can carry, from bulky outdoor gear to essential work tools. A well-chosen roof rack system unlocks that potential without sacrificing cabin comfort or driving dynamics. The decision is not merely about adding crossbars; it is about selecting a system that harmonizes with how you use the vehicle, the kinds of items you regularly transport, and the environments you encounter. In practice, roof racks come in several distinct families, each built around a core idea of how weight is distributed, how gear is secured, and how the setup interacts with wind, rain, or mud. The base decision revolves around the material and the purpose, because these two factors determine the rack’s durability, weight, and long-term cost. Aluminum, steel, fiberglass, and reinforced plastics each bring a different balance of strength, weight, and corrosion resistance. Aluminum, in particular, balances strength and lightness, making it a favorite for both industrial and off-road use. It resists corrosion and doesn’t saddle the vehicle with unnecessary heft, a practical advantage when you’re lifting gear onto the roof or navigating tight trails where acceleration and braking respond to every ounce of mass.

The foundational choice is the base roof rack system, the scaffolding that anchors your entire cargo setup. A robust base typically comprises vertical towers and foot pads that attach securely to the roof, forming a stiff platform for crossbars and any number of accessories. The features to look for here include adjustable bar spacing to accommodate different widths of gear, a universal fit to match a broad range of truck models, and a construction that withstands repeated installation and removal without loosening or warping. For fleets and regular haulers, a heavy-duty base scores points for load balance and support, since it provides a predictable, stable platform for everything from ladders and long pipes to kayaks and camping gear. When you weigh these considerations, you are not just choosing a rack; you are choosing how reliably your cargo behaves during transit, how much effort you expend in loading, and how long the system will last under daily use. If you want to explore a broader spectrum of options beyond the base framework, our roof racks guide offers detailed context and practical comparisons, including tips on fit and compatibility. roof racks.

Beyond the base, there is a world of configurations designed for specific kinds of cargo and passenger needs. A cargo basket, or open-grid roof rack, is a versatile workhorse built from steel or aluminum with raised side rails. The open design maximizes airflow and drainage, reducing the chance that water or snow will collect on your gear and delay your trip. Raised sides help prevent items from sliding off, an important feature when you’re mounting bulky or irregularly shaped items like firewood, loose tools, or muddy outdoor gear. The open mesh also makes loading easier with straps, while the airflow helps keep things drier between stops. This type shines for outdoor enthusiasts who may haul wet or dirty gear and want a flexible, quickly adaptable surface. It is not as weather-protective as a box, but it is far more forgiving for items of unusual shape or size and for trips that require frequent reconfiguration of cargo.

If your priority is protecting valuable gear from the elements while reducing wind resistance, the hard-shell box-type roof rack is the answer. These weather-resistant containers, crafted from durable plastics or composites, seal contents against rain, dust, and road spray, while their smooth exterior helps cut back on aerodynamic drag and wind noise. A box-type system turns the roof into a secure, weather-tight chamber for cameras, camping equipment, electronics, or anything you’d rather keep dry and out of sight. The integrated latches and mounting points simplify installation and ensure that components stay aligned after miles of highway or rough terrain. This design is ideal for long road trips, frequent travelers, or anyone who wants to minimize rummaging through a cluttered roof area when nature calls or the weather shifts.

For the adventurer who wants a lightweight, temporary, and weather-ready option, a canvas roof rack or roof storage solution brings a different flavor. These fabric-based systems ride over rigid frames, offering a flexible, foldable approach to increasing capacity. They are quick to install and remove, and their materials can be waterproof and UV-resistant, which helps extend their lifespan when you’re not using them. Canvas-based storage excels for seasonal gear—seasonal camping gear in spring and summer, or additional storage for ski trips in winter. The lightweight nature of canvas systems also translates to easier handling and lower fuel impact, though they require more care to ensure weather seals remain effective. For casual travelers or weekend warriors who want a simple, low-commitment solution, this family of racks can feel almost like an extra trunk on top of the vehicle rather than a permanent modification.

Winter sports bring their own specialized rack solutions, notably ski and snowboard racks. These attachments are engineered to cradle gear with padded clamps that protect edges and fabric from scratches, while aerodynamic covers minimize drag and noise. When you’re strapped for time between runs, a dedicated ski and snowboard rack makes loading gear quick and secure, reducing the chance of gear shifting during spirited drives on snow and ice. The key benefit here is peace of mind: gear stays in place, is protected from the elements, and remains easily accessible when you reach the winter resort or backcountry trailhead. The design emphasis is on gear care and dependable retention, which matters as much on a long, cold highway as it does on a forest service road.

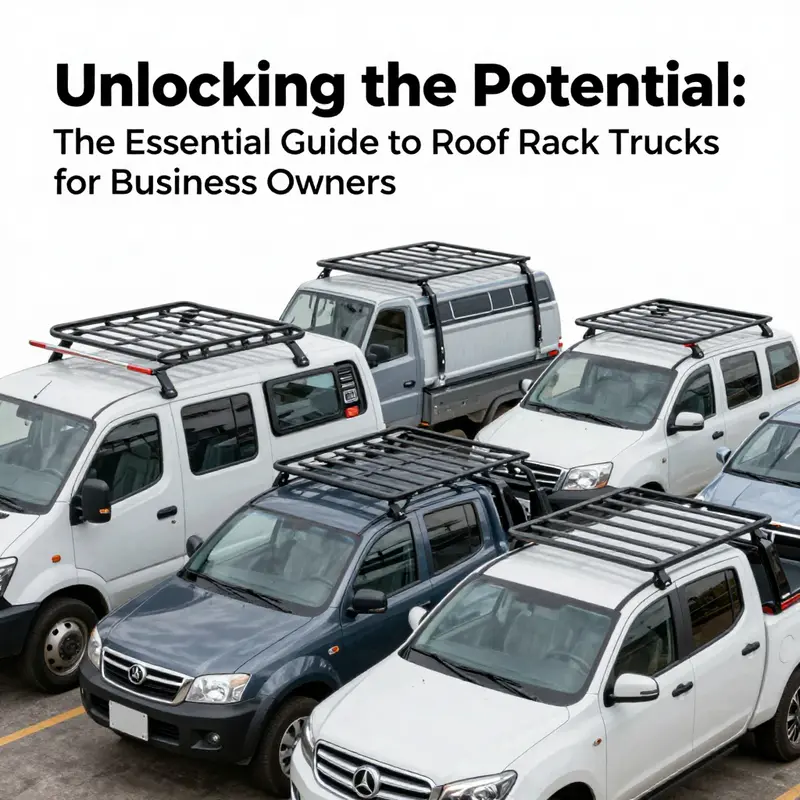

Another notable category emphasizes aluminum construction for a lighter, corrosion-resistant option suitable for rugged, long-haul use. Aluminum luggage racks provide a robust platform without the weight penalty of heavier metals. They are particularly attractive for off-road drivers and outdoor workers who need something strong enough to support ladders, gear boxes, or bulky items, yet light enough to be manageable during installation or transfer from vehicle to job site. The availability of multiple dimensions—from compact to expansive footprints—helps tailor a system to your truck’s roof geometry and the types of cargo you typically carry. In environments where salt, mud, or moisture is common, aluminum’s natural resistance to corrosion becomes a practical, long-term advantage, reducing maintenance concerns and extending the life of the system.

In daily practice, the right roof rack is a function of how you use your truck. If your work involves frequent trips with ladders, pipes, or tool boxes, a sturdy base with a secure crossbar arrangement is essential. If you’re chasing weekend adventures with bikes, boards, and dry camping gear, a combination of a base system and a specialized attachment—whether a basket, box, or ski rack—can maximize payload without compromising access or safety. If your priority is weather protection plus security, a box-type solution helps keep valuables dry and discreet. For seasonal versatility, canvas racks deliver a light, removable option that keeps the look of the truck clean when not in use. The decision is not a single feature but a balance of load capacity, ease of use, weather resilience, and overall vehicle performance on the road. It’s also about recognizing how each system integrates with the other components of the roof and the vehicle’s roof load rating, ensuring that the combination remains within safe operating limits.

The practical steps to selecting a type begin with a candid assessment of your typical loads, the shape and size of the gear, and the environments you drive through. If your cargo is heavy, irregularly shaped, or frequently changes, a base system with adjustable crossbars and a durable frame offers adaptability and reliable support. If you regularly haul wet or muddy gear, a basket or box that guards against water intrusion becomes more appealing. For sensitive equipment in blink-and-you-motta weather, the weather-tight box provides the best protection. For seasonal gear, quick install/removal and lightweight operation may trump maximum capacity. The goal is to create a system that remains resilient, serves your needs across seasons, and does not impose an unnecessary burden on handling or fuel economy. To learn more about the spectrum of options and how to choose with confidence, explore related guidance in the roof racks content we maintain, and consider how the features align with your overall truck setup. roof racks.

In the end, the best roof rack is a thoughtful combination of materials, design intent, and user needs. It should fit your vehicle without forcing verdicts on your driving style or your budget. It should withstand the elements and the rigors of daily use while maintaining ease of installation and secure cargo practices. It should also integrate with the other gear you rely on, including tie-down straps, cargo boxes, and protective padding. When you have clarity about your typical cargo, a clear sense of acceptable weight, and an awareness of the environmental conditions you face, the choice becomes less about features in isolation and more about how a system supports reliable, efficient, and safer transport. Your truck becomes more than a vehicle; it becomes a modular platform for work, travel, and exploration, with a roof rack that matches the cadence of your routine. External resources can provide deeper technical context and case studies if you want to drill down into performance, but the practical path starts with understanding the core families and how their strengths map to your most common gains in capacity, protection, and peace of mind.

External resource: https://www.toyotarackguide.com/toyota-wish-roof-rack-composition-performance-and-how-it-is-used-across-industries/

Durability by Design: How Aluminum and Steel Power Roof Rack Trucks

A roof rack system rises from mere function to a core part of a vehicle’s capability when the purpose is to carry, protect, and deploy gear in varied environments. The material heart of that system, aluminum or steel, determines how it behaves under load, how long it endures exposure to weather, and how seamlessly it integrates with the vehicle’s dynamics. In the context of roof rack trucks, durability is not just about resisting rust or surviving a rainstorm; it is about maintaining predictable performance under ever-changing weights, wind forces, and road conditions. When a driver slides a kayak onto a crossbar or hoists a ladder onto the rack, every gram of weight transfer, every gust of wind, and every bump in the road is mercilessly tested. The choice between aluminum and steel, therefore, channels the entire user experience, from how easily gear can be loaded to how the vehicle handles once the rack is loaded. The discussion of materials becomes a discussion about purpose, reliability, and daily usefulness. It is a conversation that quietly shapes the route a trip takes, the tools a contractor can transport, and the safety of both gear and driver on a long, exposed highway.

Aluminum stands out first for its strength-to-weight advantage. A rack built from aluminum keeps the overall vehicle weight modest, an attribute that matters not just for acceleration and handling but for fuel efficiency over long distances. Lighter racks reduce the additional load on roof mounts and clamps, limiting dynamic stress during braking and cornering. This quality is particularly valuable for outdoor enthusiasts who regularly switch between light loads, bikes, kayaks, or camping gear, and heavier equipment carried for a weekend project. Aluminum crossbars are typically engineered to resist corrosion from exposure to rain, salt on winter roads, and moisture carried by off road dust. The result is a system that behaves predictably no matter how many miles accumulate, with reduced maintenance needs and a longer life cycle in outdoor environments. This corrosion resistance makes aluminum a natural fit for roofs that face repeated wet cycles, seasonal dew, or damp storage conditions. In practice, aluminum racks often feel more nimble on the roof, a subtle but real advantage when driving through winding terrain or making sharp lane changes with a sizable payload. To a practical eye, this means less need for reinforcements or complicated mounting schemes aimed at compensating for heavy weight. The accessory ecosystem around aluminum racks, bike carriers, cargo boxes, and rooftop tents, also tends to emphasize portability and quick installation, traits that align with the way many owners actually use their trucks. A user can swap gear with relative ease, knowing the rack’s base is up to the task even as the load evolves for different trips. If a chapter of the road demands light, quick, and frequent changes in cargo, aluminum becomes the natural choice. For readers who want a concise primer on this idea, a broad overview of roof rack options is available here: Roof Racks for Trucks.

Steel, by contrast, brings a different harmony to the duty cycle. When the work involves heavy, bulky loads or tough environments, steel racks deliver uncompromising strength and impressive load-bearing capacity. The very term steel signals stiffness and resilience, qualities that translate into steadier behavior under extreme conditions. For tradespeople or off grid adventurers who routinely haul ladders, scaffolding, or large equipment, steel racks provide a calm, confidence-inspiring platform. The heavier mass of steel means less flex in the crossbar system, which translates into smoother load transfer and reduced risk of gear shifting during transit. That stability can be crucial when hauling unwieldy items that would otherwise threaten to bounce or shift. While steel racks demand more careful mounting and can impose greater roof-loading considerations, their durability makes them the reliable cornerstone for high-capacity configurations. The potential downside is weight: heavier racks add to the vehicle’s curb weight and raise the center of gravity slightly, factors that influence fuel economy and handling in some driving scenarios. Yet for many users, that trade-off is well worth the extra assurance and the ability to carry oversized or denser loads day after day, year after year. In modern applications, steel racks are often coated or treated to resist corrosion, combining the corrosion resistance that users expect with the structural toughness essential for industrial and heavy-duty use. When the objective is maximum reliability under demanding conditions, steel remains a fundamental option for the most rigorous tasks. The decision between aluminum and steel is rarely about one being universally better; it is about aligning material properties with the real world demands of the job, the typical load profile, and the vehicle’s performance envelope over time.

Beyond these primary structural materials, other components contribute to the rack’s overall resilience. Some systems incorporate soft-shell elements, inflatable foam supports, or tension straps to distribute load gently and maintain stability without adding excessive weight. These features complement the metal framework by cushioning gear from abrasion, dampening small movements, and simplifying the loading process. They are especially helpful when the cargo extends beyond the space defined by the crossbars, or when delicate equipment must ride with minimal vibration. The approach, combining a robust frame with thoughtful, lightweight accessories, speaks to a broader design philosophy: resilience should be achieved without sacrificing usability or efficiency. A well-considered rack system thus becomes a tuned package, where material choices intersect with manufacturing precision, attachment methods, and weather protection features.

Speaking of precision, manufacturing standards play a crucial role in translating material properties into real-world performance. Across the industry, crossbars and supporting structures are produced and tested to ensure safe weight distribution and predictable behavior under load. Standards govern the quality of the metal, its treatment, the welds or fastenings used to join components, and the tolerances that keep everything aligned during dynamic driving. This means a rack that looks sturdy on showroom floors has also been engineered to handle the stresses of wind at highway speed, pothole jolt, and the repeated cycles of loading and unloading. In practice, such standards translate into consistent outcomes: a rack that remains square, a mounting system that holds fast, and a long service life even when used in challenging environments. For those who want a tangible sense of what high-quality manufacturing implies, the existence of full quality control and rigorous inspection protocols is an important signal—100% inspection before shipment, precise material specifications, and documented testing—though the exact practices vary by producer. The upshot is clear: the durability and strength of a roof rack stem from a deliberate synthesis of material science, manufacturing discipline, and practical design.

The everyday implications of these material choices extend to how owners select a system for their vehicle. A recreational user prioritizes light weight and ease of handling, often favoring aluminum for its portability and weather resistance. A contractor or field technician, whose livelihood depends on carrying heavy ladders or bulky tools, will lean toward steel for its load-bearing margin and robust stability. Yet the choice is never black and white. The mounting system, the distribution of load across the roof, the roof’s own structural limits, and the expected weather exposure all influence the final decision. The size and shape of the rack, the number of crossbars, and the configuration of the support points all interrelate with material properties to create a cohesive, reliable platform. The result is a system whose performance matches the user’s expectations across seasons and miles, with the confidence that gear will travel securely, weather will be kept at bay, and the roof remains protected by design rather than improvised adaptation.

For readers seeking a broader, more technical frame for this discussion, external context on durable rack architectures can be found in industry-oriented resources. In parallel with these general considerations, it can be helpful to consult examples of rack systems with a proven track record of reliability and a design language that emphasizes load distribution and wind management. As you design or choose a roof rack setup, read across the spectrum—from lightweight, modular aluminum configurations to heavy-duty, welded steel frames—and consider not just the weight it adds but how that weight is managed, how the load travels across the roof, and how the system will age over time in the environments where you operate. External context: Mountain High Roof Racks offers an in-depth look at rack architectures and materials in practice, which can provide a useful reference point for evaluating how a given system performs under real-world conditions. (https://www.mountainhigh.com.au/roof-racks/)

Enduring Utility: How Roof Rack Trucks Turn Every Jobsite Into a Mobile Workshop

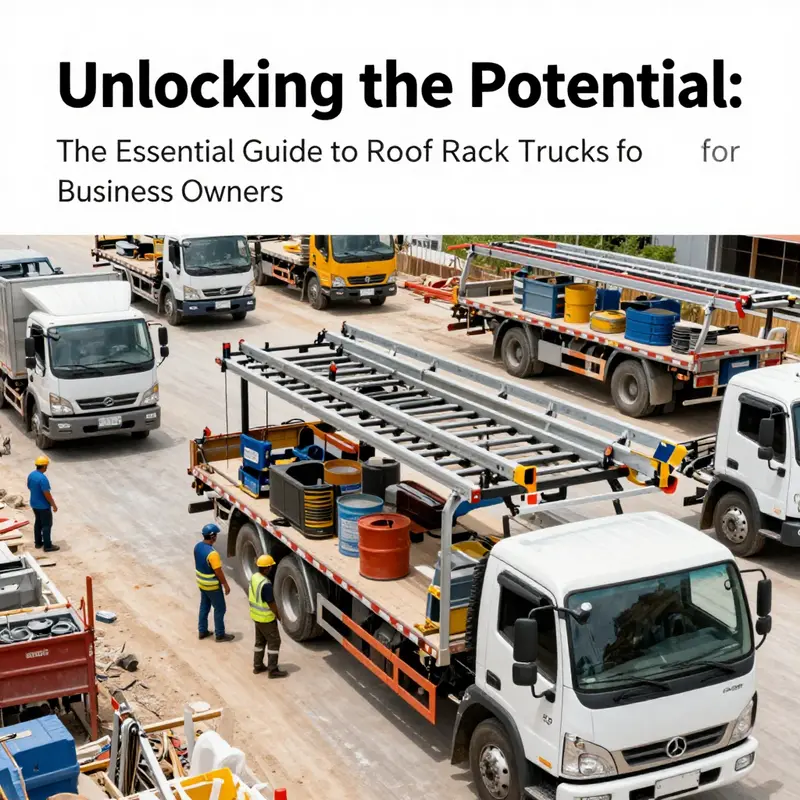

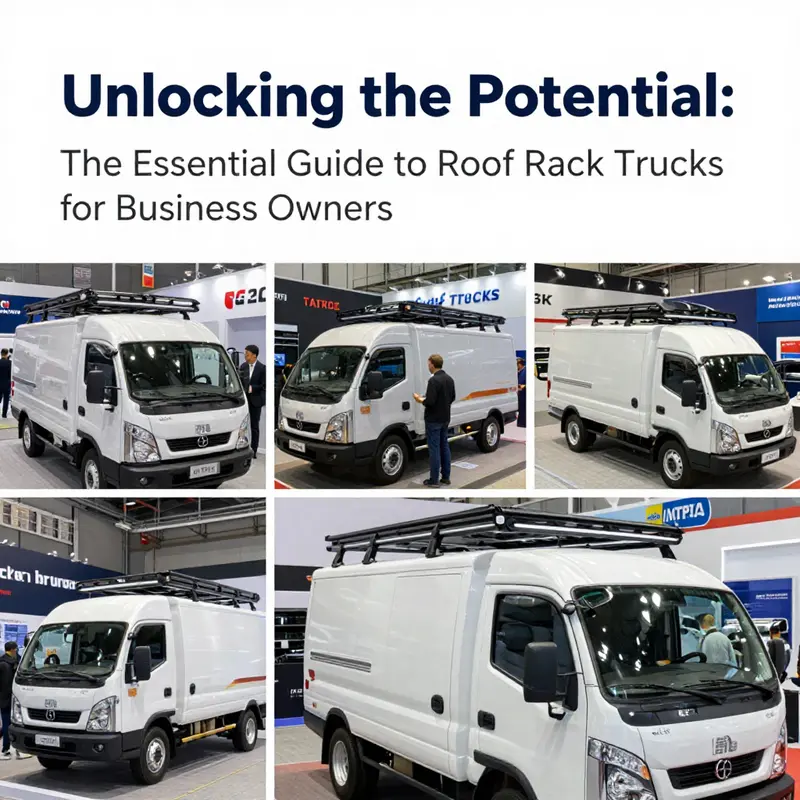

On every jobsite, a truck equipped with a robust roof rack becomes more than a means of transport. It transforms into a mobile workshop, a weather-ready staging ground, and a versatile platform for carrying the kind of bulky, irregular loads that would overwhelm a standard cargo bed alone. The industrial appeal of these systems rests on three core strengths: durability, adaptability, and efficiency. Durability is born from design choices that matter in the field—heavy-duty materials, secure mounting, and load pathways that distribute weight evenly across the roof. Adaptability comes from modular attachment points and a growing ecosystem of accessories that can be combined or removed as demands shift from day to day. Efficiency arises from simplifying loading, protecting gear from the elements, and reducing the time spent on site to fetch materials or tools. Taken together, these elements promise more than convenience; they deliver a compliant, resilient mobile workspace that helps trade professionals meet tight schedules and demanding site conditions without compromising safety or fuel economy.

Material selection sits at the heart of this durability. The trade-off between steel and aluminum is a familiar calculus for fleets and apprentices alike. Steel racks offer maximum strength and resilience when subjected to heavy, rugged loads. Aluminum racks, by contrast, deliver high strength-to-weight ratios and superior corrosion resistance, making them especially attractive for long-term use on busy fleets that travel across varied weather and terrain. In industrial and off-road environments, aluminum is frequently favored for its lighter footprint on the roof, which can translate into improved acceleration, braking performance, and overall vehicle dynamics. Yet where equipment is consistently exposed to abrasive materials or salty coastal conditions, heavy-duty steel with proper protective coatings remains a pragmatic option. Each choice shapes how much payload the system can safely bear, how predictable the weight distribution feels at highway speeds, and how frequently maintenance must be performed to keep joints, clamps, and crossbars shipshape. The message is simple: the material tells a story about how the rack will behave under load, and the user should choose based on expected tasks and working environments rather than initial appearance or price alone.

A full-length rack system—spanning the length of the vehicle’s roof—remains the preferred backbone for tradespeople who routinely haul oversized or irregularly shaped materials. Long spans distribute weight across a broader roof area, reducing the risk of localized stress and bending that can occur with shorter baskets or basket-plus-tower configurations. With a proper crossbar grid, drivers can secure lumber, piping, drywall sheets, scaffolding components, and long materials like conduit with confidence. The key is to pair a sturdy rack with well-designed tie-down points, non-slip clamps, and weatherproofing that protects both the load and the vehicle’s roof from moisture ingress and sun exposure over months and years of service. When combined with professionally engineered mounting kits and thoughtful load placement, these racks minimize wind lift and noise, which are small but meaningful factors in day-to-day comfort and long-haul fuel efficiency. The overall system becomes a disciplined infrastructure: a trusted base that holds fast through repeated cycles of loading and unloading while preserving roof integrity.

The way professionals actually use these racks underscores the need for a cohesive ecosystem of components. Across trades—from construction crews to utility teams and landscape professionals—the rack is less a single accessory than a scaffold for a growing set of tools. Rooftop tents for on-site shelter, compact solar panels for quiet, off-grid power, and recovery gear such as shovels, winches, and extra cables increasingly ride above the cab in secure, purpose-built mounts. Ladders find their place on either side or rear mounting rails, supported by adjustable clamps designed to fit a range of truck widths and bed configurations. The result is a single work vehicle capable of becoming a standing-by workshop, a temporary storage hub, and a shelter for remote job sites that would otherwise require multiple trips or separate outbuildings.

Modularity further enhances the utility story. Crossbar-based systems, common in fleets that rely on rapid turnarounds, allow technicians to snap on or remove accessories as tasks change. A day might begin with material transport to a site and finish with a ski rack or cargo box for overnight equipment if the route takes the crew into a mountainous area. While these modular configurations may carry slightly lower nominal load capacities than solid basket or platform racks, their aerodynamic profiles help limit drag and keep fuel consumption and cabin noise at reasonable levels, an important consideration for fleets managing operating costs across long routes. The tradeoffs are well understood in practice: you trade a bit of maximum payload for faster reconfiguration, easier maintenance, and quieter operation on the road. This flexibility is not merely a convenience; it is a strategic capability that increases the number of tasks one vehicle can perform without sacrificing safety or reliability.

From a safety perspective, the roof rack system functions as an extension of the vehicle’s structural envelope. Load distribution matters; professionals place heavier items closer to the vehicle centerline and toward the vehicle’s stiffest sections to maintain stable handling. Proper tie-down techniques—tightening straps and using edge protectors to avoid load slippage—are as critical as the rack’s own frame design. The goal is to keep the load centered, avoid shifting during braking and cornering, and prevent moisture, dust, and debris from compromising the roof’s integrity. Maintenance routines go beyond simply tightening straps. Regular inspection of crossbars, clamps, mounting rails, and any quick-release mechanisms ensures the system remains predictable under demanding work cycles. In remote sites or after exposure to harsh weather, a proactive maintenance mindset reduces downtime and helps extend the life of both the rack and the vehicle it serves.

The professional landscape for roof rack applications is diverse, and the choice of a system reflects the daily realities of the user. Contractors frequently require no-drill solutions that preserve the vehicle’s original structure while providing robust ladder support or tool carrier capabilities. Utilities teams need stable, high-capacity racks that can withstand long, loaded hauls over rough roads and uneven surfaces. Landscapers and emergency services personnel value versatility: the same truck can deliver mulch and pipes in the morning, then carry a recovery kit and a rooftop tent for overnight standby out in rural areas. In all cases, the rack becomes a force multiplier, letting a single truck do the jobs of multiple dedicated vehicles without the overhead of maintaining a larger fleet.

Industry-wide, the trend toward integrated systems—where racks, crossbars, and accessories are designed to work together from the outset—supports better safety margins and predictable performance. The mounting hardware, the finish on the rails, and the seals around mounting points all contribute to the system’s long-term resilience. In practical terms, this means fewer unexpected failures at the worst moments and more uptime for crews that must keep moving. While the initial investment in a robust rack system may be higher than a minimal setup, the lifecycle value is clear: fewer replacements, less downtime, and a vehicle that remains relevant to changing workloads over years of service.

For readers who want to explore the range of options and how they map to daily work, a broad spectrum of resources exists to illustrate configurations and use cases. One practical step is to examine how different trucks are outfitted with roof racks and how those setups align with specific tasks. A visit to a dedicated resource on roof racks for trucks can provide real-world examples, installation tips, and a sense of which features tend to deliver the best return on investment in industrial contexts. This practical knowledge helps fleets tailor a system to their typical payloads, route patterns, and site constraints, ensuring that the investment translates into measurable improvements in productivity and safety. Access to a wide library of such configurations supports decision-making for fleets that need to optimize their mobile operational footprint without compromising on reliability or compliance.

In sum, industrial roof rack systems are not decorative add-ons but foundational elements of the modern tradesperson’s mobile toolkit. They enable a truck to carry the toolbox, ladders, long materials, and remote-site essentials in a way that maintains vehicle performance and worker safety. The best systems balance strength with lightness, rigidity with modularity, and rugged durability with practical maintenance. They are built not merely to transport gear but to support the daily grind of fieldwork—reducing friction at the site, shortening job cycles, and turning a single vehicle into a capable, adaptable workshop that can respond to a broad range of challenges. As trades continue to evolve with new equipment and on-site requirements, the roof rack remains a critical platform for extending capacity, protecting assets, and improving the efficiency of every on-road shift. For those tasked with keeping operations moving, the choice of a roof rack is a strategic decision about how effectively a truck can serve as a mobile workspace across diverse landscapes and workloads.

External resource: https://www.ford.com/trucks/ranger/roof-rack/

Internal reference for further practical context: roof racks for trucks.

Balanced Load, Steady Drive: Designing Roof Rack Trucks for Safety and Efficiency

A roof rack system on a pickup or light-duty truck is more than a simple accessory. It is a carefully engineered interface between vehicle architecture, weight, wind, and road dynamics. When designers and users talk about safety and efficiency, they are talking about a shared goal: to maximize the utility of the rack without compromising handling, structural integrity, or fuel economy. The best rack systems feel almost invisible when they are doing their job, quietly ferrying gear from one horizon to the next while maintaining the feel and predictability of the vehicle beneath. Achieving that balance begins with a deep understanding of how load, balance, and aerodynamics interact across a moving platform. It also requires a disciplined approach to choosing materials, mounting concepts, and cargo securing methods that respect both the vehicle’s limits and the capabilities of the rack itself.

Safety considerations sit at the core of every design choice. The simplest rule—do not exceed the lower of two load limits, the rack’s maximum capacity or the vehicle’s roof load rating—protects against abrupt failures that can occur when a roof rail or crossbar yields under stress. This is not just about total pounds. It is about where that weight sits and how it shifts under acceleration, braking, and cornering. A crowded, high-profile load tends to create a larger center of gravity, which raises the risk of roll motion and can alter steering response in ways that feel subtle at first but become critical in emergencies or when navigating uneven surfaces. Proper planning means distributing load evenly across the rack and securing it so that, even after hours of vibration and thermal cycling, straps stay tight and gear remains in place.

Cargo securing, though often overlooked, is a linchpin of safety. Even a well-designed rack can become a liability if the cargo is lopsided or poorly restrained. Straps and anchors must be tight enough to control movement without causing deformation of the gear itself. After the first miles on a trip, it is prudent to recheck and re-tighten, especially if the weather shifts or the content shifts during transport. Temperature fluctuations can affect strap tension and the grip of rubberized clamps. A system that anticipates this through design—redundant tie-down points, corrosion-resistant fasteners, and adjustable clamps that accommodate various shapes and sizes—tends to fare better in real-world use than a purely rigid, one-configuration solution.

In the absence of universal statutory rules governing every aspect of roof rack safety, standards such as ISO 11154:2023 provide a critical framework. This standard articulates the safety-related requirements for rack structures, even where formal regulations do not exist. It addresses weight, center of gravity, air resistance, and structural integrity, offering a baseline that helps designers evaluate performance under typical operating conditions. Importantly, compliance with such standards does not end at checkout. Many high-use applications—industrial, utility, or field-service work—call for additional testing to simulate extreme conditions: crosswinds, sudden maneuvers, and the high-load events that can occur when ladders or heavy tools are mounted. The takeaway is clear: safety demands deliberate testing, ongoing inspection, and a willingness to upgrade or modify mounting systems when real-world feedback indicates vulnerabilities. The goal is a rack that behaves as an extension of the vehicle, not as a protruding obstacle or a potential accident vehicle.

Efficiency, meanwhile, is not merely about minimizing drag for better miles per gallon. It is about preserving the vehicle’s momentum and maneuverability while exposed to wind and weight from above. Aerodynamics matter because roof racks create lift and drag that translate into fuel economy penalties and altered handling. A typical system with crossbars increases air resistance, which can shave a measurable percentage from efficiency—often in the single digits to the low teens depending on design. The best approach is to minimize drag with streamlined profiles, smooth under-bar surfaces, and balanced weight distribution. When not in use, removing the rack entirely is a straightforward way to reclaim efficiency. If the rack must remain on the vehicle, choosing a low-profile, integrated design reduces the exposed area and helps maintain smoother airflow over the cab. These decisions have a compounding effect: less wind noise, better highway stability, and smoother throttle response during climbs and descents.

Material choice plays a central role in both safety and efficiency. Aluminum and composite materials routinely emerge as favored options because they combine high strength with a favorable strength-to-weight ratio. Lighter racks place less inertia on the vehicle roof, aiding stability and reducing the peak stresses at mounting points. Corrosion resistance is another practical consideration for systems exposed to rain, road salt, and humid conditions. A corrosion-resistant rack maintains its integrity and performance over many seasons, which is especially important for commercial and utility users who rely on predictable operation year after year. At the same time, the material must support a modular approach. A modular rack system enables attaching a variety of accessories—bike carriers, cargo boxes, or rooftop tents—without compromising the base structure, while still allowing quick conversion between configurations as needs change.

A broader design decision within efficiency is modularity versus enclosure. Modular systems offer versatility and straightforward upgrades, enabling users to adapt to new tools or seasonal gear. However, they can carry trade-offs in maximum load capacity when compared to more traditional basket-style configurations. The practical implication is that a user should align the system with expected use: a daily commuter who toggles between gear may benefit from modularity and quick-change kits, while a contractor who routinely hauls ladders and heavy equipment may prioritize a higher load rating and a robust mounting solution. Compatibility with the vehicle’s roof rails or rails-and-tittings matters here; a well-matched system won’t rely on awkward adapters that introduce play or looseness over time. In real terms, this means checking fit kits, mounting hardware, and the precision of the interface between rack and roof before committing to a long-term installation.

Beyond the basic frame lies a world of attachments that expand capability while demanding thoughtful integration. Attachments such as racks for longer equipment, secure cargo boxes, and even rooftop platforms all share the same design discipline: secure, balanced, and weather-protected. When these accessories are integrated with attention to center of gravity and weight distribution, they preserve the vehicle’s steering response and braking behavior. The ideal arrangement places heavier items closer to the vehicle’s centerline and keeps lighter, more aerodynamically shaped cargo toward the ends of the rack to minimize pendulum-like movements during sudden maneuvers.

Maintenance is the quiet steward of both safety and efficiency. A well-kept roof rack remains predictable in its behavior and continues to contribute to utility rather than noise or hazard. Regular inspection should include checking fasteners for signs of loosening, corrosion, and wear. Moving parts such as hinge points, clamps, and sliders require lubrication or replacement when necessary to maintain steady operation. Weather seals should be examined for cracking or degradation, especially in climates with temperature extremes or significant precipitation. A system that offers clear service intervals and easily accessible replacement parts tends to deliver lower lifecycle costs and fewer safety surprises on the road.

Real-world operation illustrates the nuanced balance between safety and efficiency. Consider a mixed-use scenario where a tradesperson travels from a warehouse to a job site and back, carrying ladders, toolboxes, and a few heavy items. The rack must accommodate a demanding load without compromising handling during lane changes, braking, or cornering. It must also accommodate rapid reconfiguration when the day’s work changes gear or when weather shifts unexpectedly. The cognitive load on the driver should be minimized; the rack should not require constant micro-adjustments, nor should it steal attention through excessive wind noise or vibration. In practice, the most reliable configurations emerge from deliberate planning: a base system matched to the vehicle, proper mounting, and a thoughtful selection of accessories that emphasize secure attachment, balanced weight, and ease of use.

For readers seeking further practical guidance on selection and installation, a broader overview of roof rack options can be found in the dedicated roof racks guide. It offers context on different mounting schemes, compatibility considerations, and tips for optimizing cargo layouts while maintaining safety margins. See: roof racks.

Designing roof rack trucks for safety and efficiency is about respecting the limits of the vehicle, the rack, and the gear carried above. It is about anticipating how load distribution, securing methods, and crossbar geometry interact with aerodynamics and road dynamics. It is about choosing materials that resist corrosion, maintain strength, and enable modularity without sacrificing integrity. It is about committing to inspection, maintenance, and, when needed, upgrades that reflect real-world experience. In the final analysis, a well-designed roof rack is not a luxury accessory; it is a safety-critical, efficiency-conscious platform that keeps gear organized, reduces the risk of shifting cargo, and preserves the driver’s confidence on every mile of the road.

Raising the Roof: Trends, Market Dynamics, and Innovations Driving the Roof Rack Truck Ecosystem

The market for roof racks on trucks sits at a dynamic intersection of utility, lifestyle shifts, and evolving vehicle ownership. In 2023, the global roof rack market hovered around two and a half billion dollars, with a trajectory toward roughly four and a quarter billion by the early 2030s, signaling steady growth driven by versatility and professional demand. North America is a key engine of growth, with online retail shaping awareness, comparison, and purchase velocity. A single category keyword tied to roof racks commands a notable share of search and traffic on leading e-commerce platforms, while room remains for new entrants and mid-market brands to capture incremental demand through differentiated value propositions and improved fitment and installation experiences. The data point to a market that rewards clear positioning yet remains broad enough to encourage design and distribution experimentation.

Seasonality reinforces growth: spring and early summer bring trips, campground planning, and outdoor activities, boosting interest in secure transport of gear. A secondary pulse appears in autumn into early winter, when winter sports gear drives demand for low-profile, aerodynamic racks. For sellers, this translates to stock planning: seed base inventory in Q4, run campaigns in Q1, and sustain momentum through Q2 as interest peaks. Manufacturers and retailers should align product assortments with seasonal inflection points and offer flexible options to meet diverse storage and loading needs.

The product landscape for truck roof racks ranges from hard-shell cargo boxes to soft bags and open baskets, with installation spanning universal clamps to vehicle-specific cross bars. Each approach balances weight, durability, security, and ease of use, with trade-offs in wind noise and drag that affect fuel economy and cabin quietness on long trips. Materials vary by use case: aluminum for strength and corrosion resistance, steel for heavy loads, and reinforced plastics for impact resistance and lighter weight. The best configurations combine a sturdy load-bearing frame, corrosion protection, and compatibility with a wide range of accessories.

Installation narratives differ by user: personal use favors easy mounting and a low-profile look, while commercial applications seek high load ratings, rapid installation, and secure transport of ladders and tools. Universal cross-bar systems and OEM-quality racks offer a spectrum of fit and cost, underscored by the need for reliable security and predictable performance. Buyers consider aerodynamics, wind noise, and overall vehicle dynamics at highway speeds, as well as compatibility with existing accessories and anti-theft features.

In North America, major e-commerce platforms serve as primary discovery engines, supported by well-structured catalogs and accurate fitment data that reduce decision friction. The market remains accessible to mid-sized players and newcomers, with durable construction and secure load management as core pillars. For a practical map of how these pieces fit together, see Roof Racks for Trucks and related guidance.

Overall, the market favors clear value propositions, robust build quality, and a straightforward customer experience. Look for innovations in mounting geometry, clamp mechanisms, and accessory interfaces that enable flexible, reliable configurations for daily use, weekend adventures, and professional service delivery.

Final thoughts

As business owners navigate the complexities of transportation and logistics, investing in the right roof rack systems can immensely enhance operational efficiency. Understanding the various types of roof racks, the materials they are constructed from, and their applications can provide critical advantages in daily operations. Whether for industrial use in demanding environments or for personal equipment transport, the right roof rack can transform a truck’s utility. Furthermore, staying abreast of market trends and innovations can lead to smarter purchasing decisions that align with the ever-evolving needs of your business. Equip your fleet with the best roof rack solutions, and unlock the full potential of your transport capabilities.