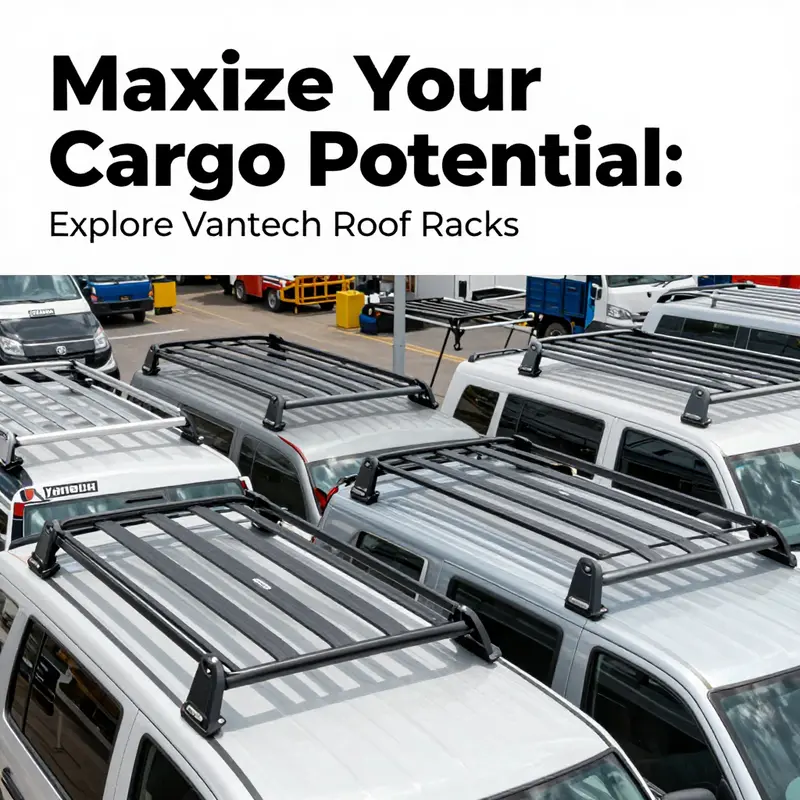

As a business owner, the efficiency of transportation can significantly impact your operations. Vantech roof racks present a robust solution for enhancing cargo capacity, allowing you to optimize your commercial vehicle for various purposes, from equipment transport to outdoor adventures. This article explores the comprehensive overview of Vantech roof racks, delves into specific models and their technical specifications, examines why they are a smart choice for business needs, and provides insightful recommendations for selecting the perfect roof rack for your vehicle. Understanding these dimensions will empower you to make informed decisions that support your business objectives.

Carrying the Horizon: A Deep Dive into Van-Ready Roof Rack Systems for Modern Vans

A van becomes more than a transportation device the moment a roof rack is mounted above it. It transforms into a mobile workspace, a rugged expedition platform, and a flexible cargo hub that can adapt to shifting priorities on the road. When you look closely at well-engineered van roof rack systems, you see more than rails and brackets. You observe a philosophy: a balance between strength, weight, aerodynamics, and modularity that allows a vehicle to carry the world without becoming burdened by it. In this context, a leading rack system for commercial and recreational vans is designed to be held to a standard not just of capacity, but of integration. It must support heavy items with confidence, yet disappear from the driving experience when empty so that fuel economy, wind noise, and handling aren’t compromised. The two primary configurations discussed in this exploration — the heavy-duty steel variant and the white aluminum low-profile variant — illustrate how a single design language can yield different paths to the same objective: dependable, versatile load-carrying that complements a van’s everyday life and its most ambitious journeys.

Consider first the heavy-duty steel variant. This configuration is built for workhorse tasks where the load is defined less by daily groceries and more by the tools and equipment that keep a business rolling. A rack designed around a substantial 600-pound capacity is cast as a platform for ladders, generators, long-length materials, and oversized gear. The emphasis here is straightforward: uncompromised reliability under demanding conditions. Every interface — from the mounting feet to the crossbars — is engineered to resist deformation and maintain clamping force across miles of highway and through the rough cadence of job sites. In practical terms, that means a rugged construction regime, where steel’s inherent stiffness translates to predictable behavior when the van is loaded with multiple items. The choice of materials is not merely about raw strength; it’s about enduring performance in the face of weather, road salt, and temperature swings. For fleets or professionals who rely on a predictable cargo platform day after day, the steel variant offers peace of mind that translates into fewer stops for readjustment and less time spent worrying about safety at speed.

In another lane of design thinking, the white aluminum low-profile variant shows a different but equally deliberate approach. The white finish isn’t just cosmetic; it signals a readiness to blend with a wide range of vehicle colors and contours, maintaining a clean, professional silhouette on the road. The low-profile geometry plays a crucial role in maximizing aerodynamics. By minimizing vertical height and streamlining the upper surface, this version reduces wind resistance and the accompanying wind noise that can become a companion on longer trips. The dimensions — a carefully proportional length, a narrow width, and a compact height — contribute to a sense that the rack is part of the vehicle rather than an external appendage. Weight is another key factor here: a lighter system reduces the overall mass the van must move, offering practical benefits in fuel efficiency and braking performance. Yet weight is not sacrificed for looks. The aluminum construction provides corrosion resistance and longevity while maintaining a rigidity that makes the rack feel sturdy when items are loaded. With a total weight of roughly 0.9 kilograms for the bare profile, this variant is designed for everyday versatility, quick mounting and removal, and seasonal use where loads may shift from camping gear to DIY equipment to emergency supplies.

From a user’s perspective, the distinction between these two configurations often comes down to a simple judgment: how much weight you’re carrying versus how often you need to adapt the rack to different missions. The steel variant shines when the load profile is heavy and stable, when the job requires a dependable base for long ladders or bulky gear. The aluminum low-profile option excels when the objective is to preserve vehicle handling, minimize drag, and keep the system visually unobtrusive. Both configurations, however, share a common thread: they’re designed with a modular mindset. The rails, crossbars, and mounting interfaces are not isolated pieces; they’re part of a flexible ecosystem that can accommodate a range of attachments and auxiliary components. It’s this scalability that makes a so-called “one rack fits many” philosophy practical, allowing a van owner or a fleet operator to tailor the system without replacing it entirely as needs evolve.

A closer look at the installation narrative helps illuminate why these two paths feel so natural together. The mounting method relies on secure attachment to the vehicle’s roof structure, typically via pre-installed side rails or through dedicated mounting points that are designed to accept a ladder rack and related accessories. This is not a one-size-fits-all proposition. Compatibility matters, and a well-conceived system recognizes that vans vary in roof geometry, roof rack mounting points, and body configurations. The ability to bolt the rack to a truck’s roof with confidence reduces the risk of loosening under vibration and speed. In practical terms, this means manufacturers test their mounting interfaces for sustained rigidity even when the van is fully loaded. A crucial part of the experience is the sense of security that comes from seeing the rack behave as a natural extension of the vehicle, not a loose implement that rattles or shifts with the wind.

The feasibility of long-term use hinges on resistance to environmental challenges. The aluminum version benefits from corrosion resistance that speaks to tolerance of salt, rain, and humid climates. The steel version achieves its durability through strong alloys and protective finishes that guard against rust in harsher environments. The result is a pair of options that don’t force a trade-off between durability and practical daily use. Instead, they offer different solutions to different workflows while maintaining a shared standard of reliability. This shared standard is not only about hardware robustness; it also reflects a design language that prioritizes ease of maintenance, modularity, and the ability to swap or add components as requirements shift. In this sense, the best rack system for any van is less a single product and more a flexible platform with a family of compatible accessories that can be reshaped on the road.

The modular ethos becomes evident when one considers the accessory ecosystem that typically accompanies these racks. Ladder stops, crossbar extensions, base mounts, and attachment points for cargo boxes or bike racks are not afterthoughts; they are integral to the overall concept. The accessory suite is designed to be intuitive to install, quick to adjust, and robust enough to hold fast during high-speed travel and rough terrain. The goal is to create a system where a user can configure a ladder’s position, swap in a ski rack for winter trips, or add a cargo container for a weekend project — all without sacrificing security or speed of setup. In practice, a van owner who frequently transitions between urban commuting, on-site work, and weekend adventuring gains a platform that does not coerce a middle-ground compromise. Instead, it supports dynamic, user-driven configurations that match the task at hand.

This narrative of compatibility and modularity is reinforced by the broader ecosystem surrounding van roof racks. The best systems are not merely about raw load capacity; they’re about how easily a user can adapt to changing life rhythms. A system that accommodates ladder storage, tools, spare equipment, bicycles, or camping gear while maintaining a civilized footprint on the highway represents a mature approach to vehicle-based transportation. In other words, the rack is part of the van’s evolving story, a narrative of growth as the owner’s needs shift from daily duties to exploration and back again. That is why the most compelling solutions are those that invite experimentation rather than constrain it, where quick detachment and reattachment of components is as straightforward as a few deliberate turns of a wrench or the click of a secured latch.

For readers who want to explore how these concepts translate into real-world decision-making, a broader look at roof rack options and their fit for different vans can be instructive. A practical step is to assess the compatibility of any system with the vehicle’s existing side rails or mounting points. If the vehicle already has a ready-made mounting framework, the setup tends to be simpler and cleaner, with fewer custom fabrication requirements. If not, the ability to integrate a compatible mounting solution becomes a central criterion. The decision also benefits from considering the typical cadence of use. For professionals who rely on a predictable, heavy-duty load path, the steel variant’s unwavering capacity offers a stable foundation. For weekend travelers who want to minimize noise, preserve fuel efficiency, and maintain a crisp aesthetic, the white aluminum low-profile model presents a compelling balance of form and function. The key takeaway is that both designs share a philosophy of practical engineering rather than mere showmanship: a rack system should disappear at times when it is not needed, yet be ready to surge into action when the next job or adventure calls.

To ground this discussion in an approachable context, it helps to think about how owners interact with the system on a typical day. A professional contractor may arrive at a worksite with a loaded rack carrying ladders and conduit. The rack’s mounting points remain steadfast, the crossbars bear the load, and the vehicle’s handling remains within expected norms. At the end of the day, the same rack can be cleared, leaving a clean roof line and a vehicle that looks almost unmodified. In contrast, a weekend warrior heading to a trailhead or campsite will benefit from the low-profile variant’s quick install-and-remove practicality and its ability to accommodate a kayak, a set of bikes, or a compact cargo box without imposing a bulky silhouette on the vehicle. This kind of operational flexibility is what elevates a roof rack from a utilitarian add-on to a strategic asset in the broader toolkit of vehicle-based mobility.

In the larger arc of vehicle accessories, the concept of modular, adaptable systems aligns with another prevailing trend: a move toward materials and designs that balance performance with efficiency. The aluminum variant’s lightweight nature translates into longer mileage and smoother acceleration, while the steel variant’s sheer strength guarantees reliability in high-demand scenarios. Both reflect a strategic understanding that modern van owners need equipment that can pivot quickly from one mission to the next without demanding a complete overhaul of the underlying platform. When integrated with a thoughtful selection of attachments and a reasonable maintenance plan, these roof rack configurations can deliver years of service with little friction, aligning with professional expectations and adventurous ambitions alike. For readers who wish to probe deeper into the practicalities of choosing and configuring rack systems, resources dedicated to broader roof rack options for trucks and vans can provide additional perspectives and comparative insights. Roof racks for trucks offers a helpful framework for evaluating compatibility, installation, and accessory ecosystems across different vehicle types, helping readers translate the concepts discussed here into concrete purchasing decisions.

In sum, the two primary configurations of a high-quality van roof rack system illustrate a core truth about modern vehicle support equipment: versatility is the brand of safety. The heavy-duty steel variant answers the call of professional use cases where reliability under load is non-negotiable. The white aluminum low-profile variant answers the call of everyday practicality, efficiency, and aesthetics, proving that performance and appearance can coexist. Together, they embody a design philosophy that values modularity, durable construction, and a thoughtful fit for a wide spectrum of vans and uses. For operators who need a long-lasting cargo platform that can grow with their business or lifestyle, these configurations offer a compelling blueprint. They demonstrate how a well-conceived rack system can extend the utility of a van far beyond what a bare chassis could carry, turning the vehicle into a genuine moving workspace and a dependable partner for every mile ahead.

External reference: https://www.alibaba.com/product-detail/Aluminum-Universal-Luggage-Roof-Rack_1600824436155.html?spm=a2700.1.women.10.6d7c1a3bOvGjLq&productDetail=Aluminum+Universal+Luggage+Roof+Rack&scm=1007.40958.113452.0&src=srp

Vantech Roof Rack Core Models and Technical Specifications: From Heavy-Duty Ladders to Low-Profile Luggage Carriers

The coil of space on top of a van is more than a practical nicety; it is the difference between a city delivery run and a full-on expedition where every inch of cargo space is a tool in the backpack of the vehicle. The core models and technical specifications of a roof rack system tailored for vans reveal a design philosophy that balances strength, weight, and modularity. For operators who live by the clock and the weather, the ability to extract capacity without sacrificing fuel economy or maneuverability is a crucial variable. In this light, the primary variants of the roof rack system are intentionally crafted to cover a spectrum of usage, from the heavy-duty needs of ladders, generators, and bulky equipment to the everyday, around-town fetches of gear, sporting goods, and camping paraphernalia. The emphasis is on a system that can withstand the demands of frequent loading and unloading while remaining reliable across climates and long-haul miles.

One of the central variants is built around a robust aluminum framework designed to maximize load capacity while keeping dead weight to a minimum. The cross-section geometry—a rectangular profile with substantial stiffness—delivers the rigidity required to resist torsion and flex when items are strapped down with tension. The aluminum choice, in particular, yields corrosion resistance that is vital for exposure to rain, salt spray, or damp mountain air, ensuring longevity even under constant use. The stated maximum payload, often framed in the upper hundreds of pounds, is a telling indicator that this variant is engineered for heavier cargo—long ladders, power tools, or bulk items that require secure stowage during highway speeds. The installation ethos around this version emphasizes bolt-on mounting to the vehicle’s roof structure, leveraging existing side rails or dedicated mounting points. This approach respects the vehicle’s original architecture, avoiding permanent alterations while offering the assurance that the rack remains firmly in place at speed and under braking.

In practical terms, the aluminum version embodies what professionals seek when they plan a daily itinerary that moves quickly between job sites and customer locations. The design supports a broad array of add-ons—ladder stops, crossbar extenders, and cargo boxes or baskets—that transform it into a modular platform rather than a fixed, single-use accessory. The compatibility story here is important. The rack system is intended to be adaptable to a wide range of van bodies, including high-roof variants and common commercial platforms. The goal is not to force a vehicle down a particular configuration but to enable operators to tailor the roof to a job—whether that means stacking long pipes for a construction crew or cradling bulky equipment for a mobile workshop. The modular philosophy also translates into maintenance and service: components can be replaced or upgraded, reducing total cost of ownership and extending the useful life of the roof setup.

A different but equally important variant centers on a white, low-profile ladder rack. The color and profile choices speak to a distinct set of priorities. White tends to blend with many vehicle colors while delivering a clean, understated look that complements the vehicle’s lines rather than competing with them. The low-profile design reduces wind resistance and associated wind noise, an often-overlooked factor when the roof rack becomes a frequent companion on long trips or daily commutes. Weighing only a fraction of a typical steel frame, this variant presents a lightweight alternative that is quick to install and easy to remove. The dimensions—long, narrow, and compact in height—are intentionally chosen to minimize the drag footprint while preserving sufficient surface area for loading a wide array of gear. In use, this variant excels for light to mid-weight loads, such as camping gear, portable tools, or seasonal equipment that does not require repeated, heavy-duty handling. The lightweight construction also helps maintain the vehicle’s center of gravity and handling characteristics, an important consideration for drivers who spend a lot of time behind the wheel.

From a materials standpoint, both variants rely on a combination of aerospace-grade aluminum and high-strength alloys to guarantee stiffness and durability without pushing the overall weight beyond practical limits. The broader family of Vantech racks often references a steel-influenced solution where certain configurations demand even higher static loads. While the aluminum variation emphasizes lightness and corrosion resistance, a few configurations within the family lean toward steel for environments where extreme payloads and busy workdays are the norm. In all cases, the engineering team prioritizes a corrosion-resistant finish, smart tolerances, and a predictable load path that helps the rack behave as an extension of the vehicle rather than an afterthought added on top. The result is a system that can endure both mundane city streets and long, demanding routes across mixed terrain.

Another critical facet of the core models is their installation approach. Bolted connections to the roof structure, rather than permanent modifications to the vehicle, are the cornerstone of a flexible, repairable, and service-friendly solution. The mounting strategy typically relies on compatibility with the vehicle’s existing roof rails or on the use of supplied bracketry that anchors securely to the roof. This is not merely a matter of convenience. It means technicians can retrofit or reconfigure the rack as vehicle needs evolve—whether adding an extra crossbar for a bulky load or swapping out a ladder stopper for a different accessory. The installation narrative also encompasses a thoughtful balance between ease and safety. The mounting hardware is designed to resist loosening under vibration and high-speed airflow. Together with anti-slip clamps or locking screws, these measures ensure that cargo remains secure through abrupt maneuvers and varied weather conditions.

The core models’ function extends beyond raw load capacity into a philosophy of modular utility. By enabling a library of add-ons and extension pieces, the system becomes a platform rather than a collection of independent parts. This modularity is particularly valuable for owners who use their vans in multiple contexts—the daily driver who also takes weekend trips, the mobile professional who rotates between containment and transport tasks, or the small business operator who must adapt to shifting seasonal demands. The capacity to add or remove components without disassembling the entire system translates into real-world time savings and operational flexibility. In practice, a ladder rack can be swapped for a long crossbar arrangement, or a cargo box can be integrated to create a secure, weatherproof storage niche. The adaptability is further enhanced by the system’s compatibility with a set of common peripherals that most van owners already have, such as ladder holders, cargo bases, and extended rails. This design philosophy—one system, many uses—elevates the perceived value of the investment and reduces the friction of upgrading as needs evolve.

It is worth noting that the core models are not merely about adding space. They are about enabling more efficient workflows and safer transportation of equipment. Safety testing under varied loads, speeds, and weather scenarios underpins the confidence that fleets and individual users place in the rack. FEA (finite element analysis), empirical load tests, and field trials contribute to a robust understanding of how the system behaves under dynamic conditions. The outcome is a balance of stiffness, weight, and damping under load that helps prevent unwanted flex, reduces the risk of fatigue in mounting points, and maintains predictable loading behavior for the user. In regions where weather is a daily factor, features such as corrosion resistance and UV-stable finishes become non-negotiable, safeguarding the appearance and structural integrity of the rack over years of exposure.

When considering which variant best fits a given vehicle and mission, the decision often hinges on payload requirements and how frequently the system will be loaded and unloaded. For operators who anticipate routinely carrying heavy gear—ladders, generators, large toolboxes—the heavier, aluminum-structured, or steel-augmented configuration with higher fixed load rating often becomes the practical choice. The emphasis in this case is on a combination of robust restraint hardware and a resilient crossbar system that can lock down elongated items with confidence. For customers whose work requires shorter trips, cleaner aesthetics, and frequent removal, the white, low-profile variant offers an attractive compromise: a slim silhouette, easier handling, and sufficient capacity for many common outdoor and travel scenarios. The decision framework is not solely about weight and load; it is also about how the rack integrates into the vehicle’s daily rhythm and how ready it is to adapt when priorities shift.

In articulating these considerations, it helps to keep the broader ecosystem of roof racks in view. The two primary variants illustrate a spectrum rather than a dichotomy: one is tuned toward maximal carrying capability with a focus on rugged endurance; the other toward minimal drag and quick turnover with a focus on convenience and aesthetics. Together, they demonstrate how a carefully designed rack system can extend the practical life of a van by turning it into a versatile platform for work, travel, and adventure. The line between utility and efficiency blurs when a well-chosen rack not only increases cargo capacity but also reduces the time and effort required to load and secure items, creating a smoother workflow from doorstep to destination. For readers who want to explore the broader landscape of roof racks and related accessories, a helpful resource covers a wide array of configurations and use cases in more general terms. See the article on roof racks for additional insights and context.

For more detailed, brand-specific information on cargo racks as a family of products, including exact payload ratings and installation instructions, the official resources provide the most up-to-date guidance. You can explore the official overview of cargo racks and their technical specifications to confirm the current offerings and recommended accessories. To complement this chapter, consider browsing through related content that discusses how roof racks integrate with different van configurations and how modular accessories expand the system’s capabilities. These discussions can offer practical tips for selecting the right components and planning a loading strategy that preserves vehicle performance while maximizing cargo security. (Internal link) roof-racks

External resources can offer a deeper dive into the official specifications and installation guides. For authoritative, model-specific data and ongoing updates, consult the official cargo racks page from the brand’s regional information hub: https://www.vantechus.com/cargo-racks. This page provides comprehensive details on payload limits, materials, mounting options, and accessory compatibility that inform a grounded decision when outfitting a van for work, travel, or adventure. This external reference complements the practical perspectives shared in this chapter and helps bridge the gap between concept and configuration.

To further situate these considerations within a broader content ecosystem, you may also find value in general roof-rack resources that discuss fundamentals of roof-mounted cargo systems, load distribution, and best practices for securing items on top of a moving vehicle. A practical entry point is available through a dedicated article on roof racks, which collates practical tips, maintenance cues, and common setup patterns that apply to many rack systems across brands. This context helps readers understand how the specific core models discussed here fit into a wider universe of roof-mounted storage solutions. roof-racks.

In sum, the core models of this roof rack family are designed to deliver a spectrum of capabilities without forcing a single use case. The aluminum version concentrates on rugged payloads and long-term durability, while the white low-profile variant emphasizes ease of use, aerodynamics, and quick turnover. Both reflect a disciplined approach to engineering: solid materials, well-considered geometry, modularity, and an installation paradigm that respects the vehicle’s original design. For fleets that demand reliability across job sites and weather fronts, for individuals who live the van life with a mobile toolkit, or for professionals who balance daily commuting with occasional heavy hauling, these core models offer a well-rounded path to expanding what a van can carry—and how safely and efficiently it can carry it.

External reference for further reading: https://www.vantechus.com/cargo-racks

Strength, Versatility, and the Vanular Edge: A Cohesive Look at Dual-Bar Roof Racks for Vans

When a van moves beyond cargo bay practicality and into the realm of mobile workspace or adventure platform, the roof rack becomes less a luxury and more a core component of the vehicle’s identity. A well-designed dual-bar ladder top rack does more than carry tools and gear; it defines how efficiently you can work, how safely you travel, and how openly you can expand the space above the cab. The principle is straightforward: a system that blends robust load capacity with thoughtful, modular design will endure through years of use, weather, and changing cargo patterns. For those who value reliability in harsh conditions, the dual-bar configuration offers a harmonized balance between strength and accessibility. In practice, this means a rack that can support ladders, generators, long poles, or large containers without compromising the vehicle’s dynamics or the driver’s control. The story of such a rack begins with two core decisions: the materials that form the crossbars and the system’s overall architecture, and then it unfolds through the way the rack couples with the van’s roof and with the accessories that extend its utility.

One of the guiding principles behind a modern dual-bar system is the shift from heavy, monolithic hardware to modular, serviceable components. The aluminum version, for example, uses high-strength aluminum to deliver a lightweight yet rigid framework. The crossbars are substantial in their profile, typically sized at a 2-inch by 1-inch rectangular section, designed to resist bending and flex when long items are perched on top. The emphasis on strength does not come at the expense of corrosion resistance; aluminum alloys chosen for these systems are selected to weather rain, road salt, sun, and humidity. That balance between durability and weight makes a difference on the scale where every kilogram taken from the top reduces the strain on the suspension and, by extension, the fuel economy and handling. In practical terms, the aluminum version can carry substantial loads—up to 600 pounds (about 272 kilograms)—without requiring the heavy mass that steel implies. This is a decisive factor for a crew that must haul ladders, long pipes, or segmented hardware, yet wants a vehicle that remains nimble and responsive on urban streets and rugged off-road tracks alike.

Aesthetics matter as well, especially when the rack is more than a tool and becomes part of the vehicle’s visual language. The aluminum version tends to look purposeful rather than imposing, a feature that aligns with professional fleets and personal builds that emphasize a clean, coordinating appearance with the van’s body lines. The practical advantage—lightness—also translates into better handling during installation or removal and easier maintenance on a busy work schedule. The second variant, often presented in a white, low-profile form, targets a different priority: wind resistance and low wind noise. This model focuses on a streamlined silhouette that minimizes drag and helps keep cabin resonance low, which translates to a quieter ride and slightly improved efficiency at highway speeds. With dimensions around 144.8 cm in length, 22.9 cm in width, and 20.3 cm in height, and a weight of roughly 0.9 kilograms, the low-profile rack is designed for proximity to the roof surface while still offering reliable attachment points for temporary or seasonal loads. The material remains aluminum, chosen for its lightness and weather resistance, but the geometry is tuned to ride closer to the roof. This matters when the goal is to carry lighter gear, camping equipment, or occasional tools without drawing too much attention to the vehicle’s aerodynamic profile.

Both variants share a philosophy of adaptability. The crossbars are not merely floating rails; they are part of a modular ecosystem that accepts a wide range of attachments. Ladder supports, vertical mounts, extended crossbar lengths, and base platforms enable the rack to transition from a simple cargo carrier to a full-fledged expedition deck. The modular design is a critical strength because most van owners evolve their needs over time. A crew that starts with a focus on each-day commute and weekend camping may soon require a more robust setup for long-range fieldwork, or the reverse may occur: a heavy-duty operation might reduce the need for occasional leisure gear, and the rack must respond to that shift without becoming a wasted investment. The ability to add or swap out components—without a complete system replacement—keeps the rack relevant for a long arc of usage. In this sense, the rack becomes less a static accessory and more a flexible platform that grows with the user’s business or life.

A practical question emerges early in the decision process: how will the rack interface with the van’s roof structure? The installation approach—whether it relies on bolts to the roof or uses clamps that engage with side rails or factory mounting points—has real consequences for safety, ease of use, and vehicle protection. The bolt-fixed approach, common in professional installations, offers a rock-solid connection to the roof’s structural members and is less prone to movement at high speeds or across uneven terrain. It demands careful alignment and precise drilling or anchor placement, and it requires confirmation that the vehicle’s roof has adequate strength or pre-existing mounting points. For those who prefer less invasive options, a clamp or clamp-rail system may be attractive, especially for conversions or vehicles that preserve their original paint integrity. In either case, the emphasis is on secure contact without compromise to the finish of the vehicle. The engineering discipline here is straightforward: you want a bond that resists vibration, wind loading, and dynamic forces when the van is accelerating on rough pavement or carving through a mountain pass.

In the broader context of van life and mobile work, the choice between aluminum and white low-profile configurations is not simply about weight or appearance. It is about how a system interacts with the owner’s daily rhythm. A professional user who routinely loads heavy items will experience tangible benefits from the heavier-duty, steel-backed or aluminum crossbar variant that can sustain long-term, high-load demands. A weekend traveler or mobile professional seeking a lean, quiet ride might value the low-profile variant’s aerodynamic edge more than the incremental gains in payload. In either case, the system’s safety credentials are paramount. The rack is designed to hold up to its rated load with testing that simulates real-world conditions, including road vibration, weather exposure, and fastener security. The goal is a layout that remains confidently stable at highway speeds, with minimal risk of loosening or fatigue after repeated cycles of loading and unloading.

Every owner who contemplates a roof rack should also consider the broader ecosystem surrounding the rack. The crossbars must be able to accommodate a spectrum of accessories—ladder racks, bike mounts, cargo boxes, sunshades, and even solar panels—so that the top surface becomes a multi-use, expandable workspace. A truly forward-looking system anticipates these needs and provides robust attachment points, reinforced anchor points, and compatible hardware across different accessory families. The modular philosophy is not merely convenience; it is a safeguard for long-term value. When the vehicle’s mission changes, the rack’s compatibility with a new set of accessories determines whether the investment remains useful rather than becoming a surplus item in the garage. The long-term payoff is straightforward: fewer needs to replace the core framework and more confidence in the rack’s enduring role in everyday transport and specialized operations.

For those navigating the purchase process, a few pragmatic guidelines help align choice with actual use. If the priority is heavy lifting and long-term, frequent payloads, the heavier, high-load version—often built with steel reinforcement or heavier aluminum sections to resist bending—tends to be the smarter choice. The strong load path reduces the risk of deformation during repeated use and under wind loads at speed, contributing to predictable performance year after year. Conversely, if the aim is daily commuting, weekend trips, or light cargo, the white low-profile aluminum model offers advantages in aesthetics and reduced drag, while giving enough strength to handle common items like a basic ladder, hiking gear, or a few containers. In all cases, installation should begin with a careful assessment of the vehicle’s roof structure, including any pre-installed side rails, roof seams, and mounting points. If side rails exist, compatibility and attachment methods may differ, but the essential criterion remains the same: a secure, corrosion-resistant, and vibration-resistant connection that keeps the load stable over time.

From a user’s perspective, the most important questions revolve around compatibility, capacity, and adaptability. How does the rack align with the van’s roof profile? Will its height interfere with roof-mounted antennas, vents, or clearance when entering garages or drive-throughs? Can the chosen model be extended with an accessory lineup that covers ladders, fuel cans, toolboxes, or solar panels? The answers lie in a system designed to be compatible with a wide range of vehicle configurations, and in a philosophy that keeps the rack accessible for upgrades without forcing a complete replacement of the core framework. A well-conceived system respects the vehicle’s original design while providing a platform that accommodates growth and change. It is this tension between fidelity to the base vehicle and ambition for expanded capability that elevates a roof rack from a mere accessory to a central tool in a van owner’s workflow. The result is a solution that can endure a movement from job site to campsite, from ladder hauling to solar panel deployment, from daily commute to expedition pace, without compromising safety or performance.

As you consider your next steps, remember that the best choice is rarely about raw numbers alone. It’s about how well the rack integrates with your vehicle’s architecture, how it preserves or enhances aerodynamics, and how easily you can adapt it to new tasks over time. A robustly engineered dual-bar roof rack—whether in a lightweight aluminum form or a low-profile white variant—meets these criteria by delivering a steady combination of strength, modularity, and ride quality. It invites you to think not just about what you carry, but how you carry it: with confidence, efficiency, and the freedom to redefine what your van can do. For readers who want a broader contextual dive into roof rack options and considerations, a summarized overview of roof racks offers a practical primer on how different designs align with vehicle types and loading needs. Roof racks

In closing, the core message remains practical and aspirational at once: a dual-bar roof rack that embraces modularity, uses durable materials, and remains adaptable to evolving use cases is a strategic asset. It supports the professional work rhythm, supports long-haul travel plans, and supports the spontaneous adventure that begins when the road opens up. The design choices—the aluminum version for strength with lean weight, or the white low-profile version for aerodynamics and daily convenience—reflect a thoughtful balance between performance and everyday usability. This balance matters because it translates into better efficiency, safer transport of equipment, and a more flexible platform for whatever tasks the van and its owner encounter. For those seeking official, detailed specifications, installation guidance, and technical support, the brand’s own resources provide authoritative information that complements the practical insights captured here. As with any serious investment in a mobile workspace or adventure rig, the key is to choose a system that harmonizes with the vehicle, your load profile, and your evolving mission, not just with the moment’s most compelling feature. For additional primary data and formal specifications, refer to the official product pages and installation manuals that anchor this category of equipment in long-term reliability and field-tested performance. External resources offer a deeper dive into the precise tolerances, mounting schemes, and compatibility matrices that keep a roof rack performing reliably through many seasons of operation.

Choosing a Vantech Roof Rack: Balancing Strength, Modularity, and Practicality for Van Life

A roof rack is more than a simple carrier; in a van-based lifestyle it becomes a carefully tuned extension of the vehicle’s purpose. It carries not just cargo, but the way you travel, work, and live on the road. When evaluating a system designed for commercial vans and camper builds, the questions aren’t only about capacity or fit. They weave together durability, aerodynamics, ease of use, and future-proof versatility. This chapter approaches the topic by tracing a practical path through what matters when selecting a roof rack that can anchor a moving workspace, a family adventure, or a ladder and tool fleet with equal reliability. It begins with compatibility, moves through load expectations and materials, and flows into how the modular nature of a two-bar ladder system expands the horizon of what a van can carry, while keeping everyday driving smooth and predictable. In doing so, the discussion ties back to the core idea that a roof rack is not just a mount for stuff; it is a platform that shapes your routes, your risks, and your return on investment as you navigate both urban streets and backcountry passes. For a concise overview of the lineup and its installation approach, see the Vantech roof rack overview.

Compatibility sits at the heart of any effective roof rack choice. Vans come in a spectrum of roof heights, mounting points, and shoulder-room for attachments, so a system that claims broad compatibility must prove it can align with a wide range of roof profiles without forcing modifications that compromise the vehicle’s structural integrity. A practical guideline is to look for designs that offer dedicated fitment for popular high-roof and modified van platforms, as these variants typically mate to the factory roof with a clean, secure interface. When a rack is described as dedicated-fit, it implies that the alignment to the roof’s crown, rail points, and edge contours is engineered to lock down without drilling or invasive modifications. If your van is a newer or less common configuration, a universal approach may be offered, but it often trades off some of that ease and security for adaptable clamps and adjustable feet. In either case, the key is a mounting system that maintains seals against the elements, resists vibrations at highway speeds, and remains rigid under load. The better systems accomplish this by using anchor points or side rails that mirror the vehicle’s original structure rather than relying solely on external clamps. A robust fit reduces wind noise and steering disturbances, so the rack feels like a natural part of the van rather than an add-on that you notice every time you pass 60 mph.

The two-bar ladder-system configuration under discussion embodies a practical balance between load distribution and accessibility. The crossbars provide a stable skeleton for large items while leaving room for specialized attachments. In this setup, the crossbars are sized to accommodate a wide range of cargo, from long ladders and beams to compact containers and bikes, without crowding the roof or impinging on cabin ingress when doors swing open. A core decision point is the material choice. An aluminum version delivers impressive stiffness with significantly reduced weight, a boon for fuel economy and handling. Aluminum also resists corrosion, which matters in varied climates—from coastal humidity to winter-salted roads—extending the life of both rack and vehicle. The other end of the spectrum is a steel-based option that trades some weight and corrosion resistance for higher raw load capacity. This can be important for professional users who routinely transport heavy equipment, like long ladders, generators, or multi-piece tool systems. Capacity figures are not merely numbers; they signal the design intent behind the product. A rack capable of supporting substantial loads gives you the confidence to plan ambitious trips or mobile work setups, whether you are a contractor, a field technician, or a traveling family with heavy winter gear and camping equipment. The exact numbers matter—and in the right context, a 600-pound capability or a similar high rating is not just about carrying more; it signals a reserve margin for shifting loads, securing tall items, and accommodating unexpected gear during a trip.

Beyond raw strength, the material choice informs maintenance, aerodynamics, and the long game of ownership. Aluminum, with its lightness and natural corrosion resistance, often yields a modest, real-world gain in efficiency and reduced stress on the vehicle’s roof structure over time. A lighter rack means less moment at speed and less fatigue for the mounting points during frequent, heavy-use periods. In adverse weather, aluminum’s surfaces resist rust and pitting that can otherwise degrade fitment or require earlier replacement. Steel versions, when properly treated, offer exceptional rigidity and resilience for continuous, industrial use. They can be a practical choice when the priority is perched, heavy-duty carrying and when the environment presents aggressive wear and tear. The choice is not purely technical; it affects maintenance cycles, cleaning routines, and even the cadence of inspection. As such, a thoughtful buyer weighs how often the rack will be loaded to near capacity, how climate exposure will shape the finish, and what kind of upkeep the owner is prepared to perform to keep the system performing optimally.

Modularity is another pillar in building a rack that truly serves as a platform rather than a mere carrier. A ladder-system rack designed with modularity in mind invites an ecosystem of add-ons that can transform the roof into a flexible workspace: ladder holders, extended crossbars, cargo bases, bicycle racks, and even weatherproof cargo boxes. The essence of modular design is not just the number of accessories but how intuitively they integrate with the base rails and with each other. When attachments are designed to lock into standardized slots or brackets, customization becomes quick and reliable. This is particularly valuable for van owners who move between roles—diligent contractors one week, campers the next. The ability to reconfigure the rack for a long-haul route that includes a generator and a ladder, or a weekend excursion that prioritizes bikes and a rooftop tent, translates into real-world savings in time and effort. The modular approach also supports upgrades as needs evolve. If your initial plan is to carry only light camping gear, you might start with a lean configuration and later add a bike rack or a storage box as confidence and usage grow. The pathway from a simple base rack to a fuller system is often a matter of choosing compatible add-ons that preserve the original mounting geometry and seal integrity, which helps prevent water ingress and loosening of fittings.

As with any vehicle accessory, installation is the bridge between concept and reality. A well-engineered rack installation respects the van’s structural points, preserves paint integrity, and minimizes the risk of loosening at speed. Ideally, the mounting system uses dedicated attachment points integrated into the roof structure or vehicle rails, avoiding drilling into the vehicle skin or compromising the integrity of the roof. When pre-installed side rails or factory mounting channels exist, the rack should align with these anchors with precise tolerances. For universal-fit systems, the mounting hardware must compensate for differences in roof curvature and channel geometry without forcing forceful bending of the rack frame. In all cases, the tightness of fasteners, the seal around mounting feet, and the ease of future maintenance are the markers of a thoughtful installation. Regular checks—especially after long trips or backcountry routes—help ensure that bolts remain torqued to spec and that no corrosion or wear has crept into the attachment hardware. A happy outcome is a rack that remains quiet at speed, grows with your needs, and survives the test of time without demanding frequent interventions.

From a practical viewpoint, capacity planning deserves careful attention. It is natural to imagine a preferred set of cargo—ladders, toolboxes, long poles, or bulky camping gear—but real-world use often introduces surprise items that must be accommodated safely. The recommended approach is to evaluate typical loads in weight, volume, and height, and then consider a contingency margin for tall items like ladders or crosswise cargo boxes. Signs of overloading are not only the potential for interior cabin interference or aerodynamic penalties, but more important, elevated stress on mounting points and roof panels. Responsible owners distribute weight more evenly along the crossbars and avoid stacking weights beyond what the crossbar system was designed to manage. For example, longer items should be secured at the center or supported by additional attachment points to reduce strain on any single point. In addition to load management, think about wind moments generated at highway speeds. A rack that is overly long or poorly aerodynamically shaped can tug on the vehicle at high speed, encouraging tire wear and complicating steering feedback. A well-designed system mitigates those effects by maintaining a low profile, smooth lines, and reliable mounting hardware that survives vibrations and environmental exposure.

The selection journey also involves validating the coatings and finishes that defend against the elements. Aluminum components benefit from natural oxidation resistance, but exposed edges and fasteners still require attention. Finishes like anodizing or protective coatings on steel parts delay corrosion and help maintain a uniform appearance as years of use accumulate. The visual cues of wear—dull edges, loose fasteners, or flaking coatings—are early signs that maintenance is due, not a sign that the rack has failed. Routine care—washing, drying, and quick lubrication of moving parts or quick-release mechanisms—extends the life of the system and improves ease of use year after year.

A final thread in the selection tapestry is the broader ecosystem of user experiences and feedback. The best approaches to roof racks often emerge from a community of users who share installation tips, maintenance insights, and real-world performance stories. When possible, reference experiences from owners of similar vans or use cases to gauge how a given model behaves under continuous daily use, long trips, or high-gear hauling. A credible choice balances objective specs with subjective experience: how do the attachments feel in hand, how easily can a user reorder or replace components, and how well does the system integrate with the van’s finite interior space and exterior silhouette? These practical checks are often the deciding factor when two options appear to be equally capable on paper.

If you are looking to begin or refine your exploration, a concise, user-oriented resource that distills the lineup and its installation strategy can be a useful starting point. See the Vantech roof rack overview for a focused snapshot of what the family of products offers and how the mounting geometry translates into real-world use. While not every van will require the same level of customization, the guiding principles—compatibility, strength, modularity, and ease of use—remain consistent across the range. The goal is to choose a platform that respects the vehicle’s design, fulfills current needs, and remains adaptable for future adventures or job-site demands. In this sense, a roof rack is not a fixed asset but a flexible platform that scales with your ambitions, not the other way around.

As you think about the next steps, consider the broader context of your van’s role in your life. If your work depends on reliable transport of heavy, awkward loads, the steel-centric approach with a higher capacity could be a sensible baseline. If your days emphasize mobility, fuel economy, and unintrusive aesthetics, an aluminum system with a low-profile footprint can be the smarter investment. Either way, the core philosophy remains: a roof rack should feel like an integrated extension of the van, not a foreign object perched on top. The right choice empowers you to plan more ambitious trips, carry more gear with less effort, and navigate both highways and dirt roads with a calm, organized confidence. For many van owners, this translates into a broader sense of freedom—the ability to adapt quickly to a new work assignment, a remote camping spot, or a family road trip without reconfiguring their vehicle every time. In the end, the rack is a tool; its quality, modularity, and integration define how reliably it serves your evolving journeys. External resources like detailed product references can further illuminate the options, including comparisons of aluminum versus steel constructions, load ratings, and installation workflows for specific van models. External resource: https://www.alibaba.com/product-detail/Durable-Aluminum-Roof-Rack-For-Toyota-Hiace_1600892238158.html

Final thoughts

Investing in a Vantech roof rack is a strategic decision for any business owner looking to enhance transportation efficiency and safety. By choosing the right model tailored to your specific needs, you can significantly boost your commercial vehicle’s functionality. This investment not only facilitates easy transport of equipment and goods but also ensures long-term reliability and durability. Whether you require a robust aluminum version for heavy loads or a sleek low-profile model for lighter needs, Vantech offers versatile options that align with your business goals. Elevate your transport capacity and operational efficiency with Vantech roof racks.