For business owners in industries reliant on heavy-duty vehicles, maximizing storage and organization is essential. Merritt Equipment has designed a range of aluminum truck storage boxes that not only offer durability but also optimize space utilization. In the following chapters, we will explore the functionality and features of Merritt truck boxes, the versatile applications across different sectors, and their construction designed for heavy-duty use. Understanding these aspects will equip you with valuable insights to enhance your operational efficiency.

Between the Frame and the Road: The Craft, Function, and Durability of Merritt Truck Boxes

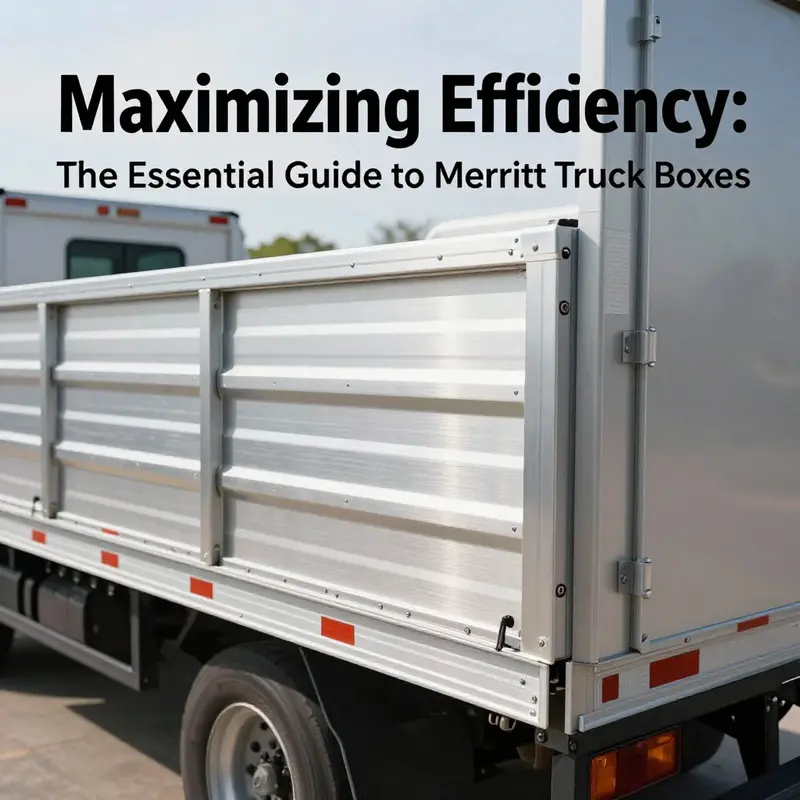

Every truck carries more than its payload when it carries gear: it carries the expectation that tools and materials will be ready at hand, protected from the weather, and organized enough to be found in a hurry. The space between a truck’s frame and its cab is not an empty void but a carefully engineered corridor where storage can live without intruding on maneuverability or payload. This is where a family of aluminum truck boxes shines, turning a potentially wasted gap into a disciplined system of access, durability, and practicality. The design philosophy behind these boxes leans into three core advantages: maximizing space without compromising structure, shedding weight while increasing strength, and weatherproofing that keeps contents secure in harsh conditions. The result is a storage solution that does more than hold gear; it becomes a modular extension of the vehicle itself, a compact workshop that travels with the truck rather than a separate cargo add-on. The materials and manufacturing approach underpinning these boxes reinforce that idea. Aluminum alloy provides a high strength-to-weight ratio, so the boxes resist denting and bending even when hauled over rough terrain or loaded with heavy tools. Aluminum also resists corrosion when exposed to road salts, weather, and splashes from muddy off-road surfaces, a practical trait for fleets that operate year-round. Alongside the metal’s inherent toughness, the doors are designed to seal tightly. Weatherproof seals around the perimeter are automotive grade, engineered to keep moisture and dust out while enabling smooth operation of hinges and latches. A welded-in installation kit further promotes a secure, rigid mounting that minimizes movement while the truck is in motion, reducing wear on both the box and the surrounding frame. In short, this is a storage system designed not only to hold gear but to endure the conditions of the road and the rigors of daily use. For builders and operators who must rely on steady access to hand tools, fasteners, and small equipment, the story of these boxes is as much about reliability as it is about capacity. The concept of space optimization is not just about cramming more into a box; it is about shaping a balance between available real estate and the demands of a busy workday. Every dimension is chosen with purpose: the most common saddle-style configurations mount on both sides of the frame, creating a mirrored corridor of compartments that stay out of the truck’s wheel wells and tailgate while remaining near the rider’s reach. These saddle boxes cover a range of scalpels-and-screwdrivers heights, from compact 12 inches up to 36 inches, with the smaller sizes offering additional internal features that enhance organization. On the 12-inch and 18-inch models, there are optional internal chain rack dividers and foldable handles that fold flat when not in use, preserving clearance and reducing snag hazards as the truck moves through narrow alleys or confined job sites. The ability to tailor the interior to a specific tool set makes a practical difference, particularly on crews that cycle between carpentry, electrical, plumbing, or equipment maintenance tasks. The chain rack dividers act as a low-profile way to keep long items from shifting during transit, while foldable handles offer ergonomic flexibility for manual loading and unloading in constrained spaces. These attributes exemplify a larger truth about these boxes: the hardware is not just a container but a framework that respects the geometry of the truck and the rhythm of work. A different approach appears in the between-the-frame toolbox line. Installed in the narrow corridor between the rails, these boxes reclaim space that would otherwise lie fallow. This design choice matters because it acknowledges a universal constraint of work trucks: every centimeter of usable space on frame, underbody, and between components is precious. By situating storage between the frames, operators gain additional capacity without expanding the vehicle’s footprint or compromising access to other equipment. The between-the-frame models are particularly appealing to fleets that must balance tool quantity with cargo volume, or to operators who frequently switch configurations depending on the month, season, or project. Consider how forestry operations illustrate the value of specialized storage: logger boxes designed for rugged, demanding environments provide a dedicated home for specialized tools and materials used in logging and forestry support work. In environments where weather, dust, and the constant presence of moisture threaten the integrity of smaller containers, a purpose-built logger box offers robust protection and a proven mounting interface. These boxes are built with the same aluminum core and weatherproof sealing, but their dimensions and internal layouts reflect the unique tool assortments found in forestry tasks—shovels, hand saws, wedges, felling aids, and fasteners that must survive outdoor exposure and frequent handling. The specialty line demonstrates how Merritt’s design language translates to industry-specific reliability, emphasizing that the same fundamental materials and construction principles can be adapted without compromising performance or durability. Beyond the primary box families, the range expands with a thoughtful suite of accessories that broaden the boxes’ utility and ease of use. Installation kits, chain rack dividers, fixed handles, and foldable handles are not merely add-ons; they are integral components that shape the user experience. Installers benefit from welded-in kits that simplify mounting, ensuring consistent alignment and a secure fit across a variety of frame configurations. The chain rack dividers enable a cleaner separation of tools within a single compartment, a feature that pays dividends when job sites demand fast, precise access rather than rummaging through clutter. The fixed and foldable handles give operators options for grip and leverage, enabling one-handed opening in tight spaces, or a compact profile when clearance is at a premium. The attention to handle geometry—how it folds, how it locks, how it cooperates with weather seals—speaks to a broader design principle: that every touchpoint on the box should contribute to a smoother workflow. A rack of tools is only as useful as the box’s ability to keep them dry, organized, and accessible, and the user’s ability to operate the box without hindrance. This is where manufacturing discipline comes to the fore. All products are manufactured in the USA, a commitment that supports consistent quality control, traceable supply chains, and robust engineering practices. The consistent standards that accompany domestic production translate into predictable performance across fleets and seasons. It also means customization options can be delivered with shorter lead times as needs evolve on a job site or in a company’s maintenance program. The result is a storage system that embodies a practical transparency: you can see at a glance what you’ve stored, where it sits, and how the container was built to endure. The combination of light weight, high strength, weatherproof doors, and rugged mounting systems makes these boxes an attractive option for operators who care about long-term ownership costs. Weight reduction is not an abstract benefit when every kilogram shaved from the truck’s payload translates into more usable carrying capacity or improved fuel efficiency during routine trips. Durability is not merely about resisting scratches; it is about remaining dependable after repeated openings and closings, under sun and snow, in dusty yards, or after back-and-forth trips across rough pavement. The doors themselves—sealed tightly along their entire perimeter—offer more than weather protection. They help maintain a stable internal climate for tools that’re sensitive to temperature and humidity, contribute to reduced rust and corrosion on metal tools, and ease the burden of maintenance because the interior remains cleaner and less prone to moisture intrusion. The combination of aluminum construction and weatherproof sealing addresses one of the most persistent pain points for anyone who loads and unloads on a regular basis: moisture and grime undermining hardware and fasteners. The design also considers the truck’s aesthetic and resale value. A uniform, professional exterior—free of denting and with clean lines at the frame rail—speaks to a level of care that extends beyond daily use. A well-maintained toolbox impacts not only immediate productivity but future resale value, because it signals a vehicle that has been properly equipped and maintained. In this sense, the boxes function as a modular upgrade to the truck’s instrument panel of usefulness. They create a steady, repeatable workflow: tools are easy to locate, access is intuitive, and the risk of damage or loss is markedly reduced. The practical benefits are complemented by a clear sense of purpose and reliability, a familiar rhythm that seasoned crews come to rely on as they move from job site to job site. For readers seeking more background on the material approach and product line, the underlying philosophy and details of the aluminum construction are summarized in the Merritt aluminum overview. This reference provides context for how the raw material choices translate into performance in the field. Merritt aluminum encapsulates the idea that form follows function when it comes to truck storage, and it places these boxes within a broader ecosystem of accessories and mounting options designed to keep a vehicle ready for work. The story of these storage solutions is not just about what they hold, but about how they hold it: securely, accessibly, and predictably amid the unpredictable cadence of daily service, weathering, and demand. In the end, the value of Merritt’s truck boxes rests on their ability to transform the frame’s blank space into a disciplined, reliable work zone that travels as a seamless extension of the crew. The design language—lightweight yet strong, sealed against the weather, and anchored by welded installation kits—remains consistent across saddle, between-the-frame, and logger configurations, with each model offering its own tailored interior geography to fit distinct tool kits. This continuity ensures a smooth handoff from one job to the next: operators can expect the same intuitive use, the same confidence in weather protection, and the same straightforward maintenance routine, no matter which box size or model is chosen. The result is not merely a storage container but a practical system that respects the vehicle’s architecture, the worker’s workflow, and the demands of real-world use. It is, in essence, a bridge between space and utility—a small, proven engineering solution that keeps tools dry, organized, and accessible while the truck continues to serve as the mobile workshop. Weatherproof doors, reinforced seals, and durable mounting hardware are not afterthoughts; they are the hinge points of a design philosophy that treats the truck as a continuing work environment, not a static transport. When crews step back from the job site and see a neatly arranged, easy-to-navigate toolbox array, they are reminded that the frame itself was designed to carry more than components; it was designed to carry work itself—efficiently, reliably, and with a quiet confidence that every tool can be found when needed. The story of these storage boxes, then, is a narrative of integration: how space is reclaimed, how weight is managed, how durability is ensured, and how a simple metal enclosure becomes a trusted partner on the road. It is a narrative that aligns with a broader industry aim: to enable workers to perform with less friction, fewer interruptions, and more time focused on the task at hand. The chapter in the larger discussion of merritt truck boxes emphasizes the idea that a well-conceived storage solution does more than store. It defines the rhythm of work, supports safety and efficiency, and contributes to a vehicle’s lifecycle value. In that sense, the smallest choice—whether to add a saddle box or a between-the-frame unit, or to opt for a logger-design box—has a ripple effect on daily operations, fleet performance, and the long arc of maintenance. The enduring takeaway is straightforward: in an environment where space is at a premium and conditions are unforgiving, a purpose-built storage system that respects frame geometry, employs lightweight yet strong materials, and seals out the weather will consistently outperform improvised, makeshift arrangements. It is a reminder that good design in this space is less about novelty and more about a disciplined, repeatable approach to organization and protection. The road rewards those who plan ahead, who invest in robust mounting and sealing systems, and who recognize that the point of storage is less about capacity alone and more about dependable access, broad compatibility with work styles, and a durable relationship with the elements. Where space is scarce, the right truck box does more than fill it; it clarifies it. Where weather is a risk, the right seal protects it. And where the job demands speed and accuracy, the right interior layout makes each tool instantly findable, enabling the work to progress with confidence. In that sense, Merritt truck boxes become more than containers; they become the quiet, steady backbone of a well-run mobile workshop.

Between Frame and Frontline: Aluminum Truck Boxes Redefining Storage

Aluminum storage boxes mounted between a truck frame turn a vehicle into a disciplined workspace. Designed for durability, weather resistance, and modularity, these boxes maximize space while preserving payload and tool security on demanding sites.

They rely on a lightweight yet strong alloy that resists corrosion and endures temperature swings, while weatherproof seals keep dust and moisture out. Rugged mounting kits and reinforced hinges ensure reliable service across years of daily use.

Modularity defines the lineup: saddle boxes along the sides, between-the-frame configurations for tight spaces, and configurable dividers that keep cords, fasteners, and tools neatly organized. This flexibility supports a wide range of trades and lets fleets tailor storage to their evolving needs.

Armor on the Frame: The Engineering Behind Merritt Truck Boxes for Real-World Heavy-Duty Use

When fleets pull out onto job sites or highway corridors with a trailer full of tools, spare parts, and essential hardware, the integrity of the storage solution is as critical as the engine that carries it. The chapter that follows probes the core of Merritt truck boxes—the way their construction and durability are engineered to withstand the harsh realities of heavy-duty use. These aren’t cosmetic add-ons; they are rugged, purpose-built systems designed to maximize payload security, optimize space between the vehicle’s frame, and endure the daily grind of rain, dust, vibration, and impact. In the world of commercial trucking and fleet management, that combination translates into a tangible reduction in downtime, faster workflow, and a lower total cost of ownership over the life of a build.\n\nThe centerpiece of Merritt’s approach to durability rests on a deliberate balance between strength, weatherproofing, and practical mountability. The robust design language is evident in the high-side configurations that give tools and equipment ample room while minimizing the risk of snag or interference with underbody components. A representative package in this category—expressed in terms of size and form—speaks to the scale of work these boxes are meant to handle: a length of 1750 millimeters, a width of 550 millimeters, and a height of 850 millimeters. Those dimensions strike a careful compromise. They provide generous interior volume for daily essentials—wrenches, cordless drill sets, hoses, fasteners, and spare hardware—while preserving the structural integrity needed to resist torques and bending moments that come from driving on mixed terrain or making tight corners in urban yards. The high-side profile also contributes to a confident canopy, a design choice that works in concert with the weatherproofing strategy to shield contents from sun, rain, spray, and road grime.\n\nA salient thread running through these boxes is the commitment to a solid canopy design. The canopy isn’t merely a cover; it is an active part of the chassis’s protective envelope. In the rough-and-tumble environment of construction sites and forestry operations, tools and materials are continually exposed to weather and impact. The canopy helps create a buffer against those forces, reducing the likelihood of water intrusion and the gradual degradation that occurs when moisture migrates into tool rails, fasteners, and coated surfaces. But a canopy alone cannot guarantee lasting performance. That performance rests on a suite of engineered features that work together, beginning with the materials and the joining methods.\n\nMaterial choice is foundational to durability, and Merritt’s engineering philosophy emphasizes high-quality materials and manufacturing processes that meet or exceed industry standards. The result is a system that resists the daily assaults of dust and moisture, while also enduring the bump-and-bounce of highway travel and off-road environments. The objective is not only to survive but to maintain reliable functionality year after year, even in fleet-intensive scenarios where a box may be opened dozens of times each shift. In this regard, the approach aligns with broader industry trends noted by leading industry voices, where durable truck components are not optional but essential to operational efficiency. The emphasis on quality—paired with a clear understanding of how durability affects total cost of ownership—helps fleet executives make decisions grounded in data, performance, and long-term value. This is the same mindset that underpins the decisions described by reputable sources that highlight a data-driven approach to equipment selection and lifecycle planning.\n\nWithin the construction framework, the doors and seals are a critical interface between the interior environment and the world outside. Merritt boxes employ weatherproof seals around the door perimeters, with automotive-grade materials designed to withstand repeated cycles of opening and closing without losing their seal. The integrity of these seals determines whether rain or road spray becomes a recurring issue inside the box, potentially compromising tools and sensitive hardware. The value of a robust seal extends beyond weather resistance; it also contributes to security and content protection. If moisture undermines lubricants or causes corrosion on metal surfaces, the maintenance cycle lengthens and the box’s lifetime cost climbs. The choice of seal material and geometry matters, and the industry standard-setting context reinforces that a well-sealed enclosure is a practical investment in reliability and uptime.\n\nThis durability story is complemented by the mounting technology that secures the box to the vehicle frame. Merritt’s boxes are designed with weld-in installation kits that provide a stable, vibration-resistant anchor system. The welded components minimize movement that could otherwise stress fasteners or allow the box to shift under heavy loads. In fleet environments, where the truck spends long hours on the road and the frame is subject to dynamic loads, such mounting solutions.\n\nThe concept of space is inseparable from durability in this conversation. Between-the-frame installations exploit otherwise unused space along the vehicle’s frame, expanding a fleet’s storage capacity without sacrificing cab or cargo area. This approach is particularly relevant for operators who need to maximize containerized storage without increasing the vehicle’s overall footprint. Saddle boxes, mounted on both sides of the frame, represent another widely used configuration that balances accessibility with protection. The saddle box format provides ready access from both sides, enabling technicians to retrieve a hammer, a drill bit set, or a chain rack without detours or long detours into the truck bed. In many cases, optional internal chain rack dividers and foldable handles are available to tailor each box to the operator’s workflow. These small but meaningful enhancements can reduce the time spent digging for gear, helping crews stay on schedule and on budget.\n\nThe durability story is not limited to the box body; it also extends to how contents are managed and organized. A well-designed storage system introduces internal features that maximize usable space and minimize the risk of items shifting during transit. For example, internal dividers or optional chain racks can keep bulky or sharp tools from bouncing around and causing dents or scratches on the box interior or on adjacent equipment. The modularity and configurability of the interior layout reflect an understanding that tool inventories evolve over time. A robust system thus supports long-term productivity, allowing crews to reconfigure storage without replacing the entire enclosure.\n\nIn discussing the durability of Merritt truck boxes, it is important to reflect on the lifecycle implications for a fleet. A durable storage solution reduces the frequency of replacements, minimizes the risk of lost or damaged tools, and lowers the administrative overhead associated with inventory mismanagement. Heavy-duty fleet operators understand that the cost of ownership is not limited to the sticker price. It includes maintenance labor, downtime, and the risk of mischaracterized or misplaced equipment. The durability features—steel or other high-strength materials, canopy protection, weatherproof doors, robust seals, welded-in mounting, and space-efficient configurations—work together to improve operational efficiency. This reality resonates with the broader discourse in industry publications that highlight how durable components empower fleets to plan more predictable maintenance schedules, improve uptime, and optimize utilization of drivers and equipment. As fleets scale, these durability characteristics become increasingly consequential.\n\nAmong the key design decisions that shape long-term performance is the material selection. While the boxes described in these design notes are built with strong, high-side configurations, the broader Merritt lineup also includes aluminum variants in some models. Aluminum combines lightness with corrosion resistance, which can translate into easier handling during installation and potentially reduced stress on mounting points. The aluminum option is particularly appealing for operators who prioritize weight savings or have a premium on reduced vehicle mass. To explore that pathway and understand how it complements the steel-heavy lineup, the reader can consult the broader range of Merritt aluminum offerings. For a deeper look into these aluminum variants, see the Merritt aluminum resource page, which details the aluminum construction options and how they support durable storage in demanding traffic contexts. Merritt aluminum\n\nBeyond the box itself, the entire ecosystem of components—from canopy design to installation kits and optional organizers—plays a role in durability. The welded-in installation kits provide a secure, tamper-resistant mounting foundation that stays put even when an operator must back up against a loading dock, traverse uneven ground, or negotiate tight industrial spaces. The hardware and fasteners chosen for these kits are deliberate. They are selected to resist corrosion, maintain clamp strength, and tolerate the vibrations that are intrinsic to trucking and field service. This attention to detail demonstrates that durability is not a single attribute but an integrated system of design choices that reinforce one another over the vehicle’s lifetime.\n\nIn practical terms, the durability of Merritt truck boxes translates into tangible effects on fleet operations. A box that resists water intrusion protects tools from rust and moisture damage, extending their usable life. Sealed doors with reliable gaskets reduce the likelihood that a technician arrives to find corroded fasteners or seized components. A dependable mounting system means less downtime for adjustments, alignments, or re-securing equipment after rough terrain or a heavy load. The result is a truck that remains prepared for the next job with minimal delay, a small but meaningful contributor to schedule adherence, fuel efficiency, and customer satisfaction. These are the factors fleet managers evaluate when weighing capital expenditures and maintenance budgets, and durability emerges as a central criterion when comparing competing storage solutions.\n\nAll of these considerations coexist with a broader industry context that emphasizes standardization, safety, and quality assurance. The materials, manufacturing processes, seals, and installation strategies align with established industry expectations for reliable, high-performance site storage. When a fleet weighs a storage choice, durability becomes the proxy indicator for a wider portfolio of performance metrics: aggregate downtime, maintenance headcount, replacement cycles, and the ability to protect a company’s investment in field personnel and equipment. The presence of solid canopy designs, weatherproof doors, automotive-grade perimeter seals, and welded-in installation kits demonstrates a mature engineering approach that understands the realities of real-world use. It is this integration of form and function that makes Merritt truck boxes a compelling choice for operators who must balance capacity, security, ease of use, and longevity across diverse work environments.\n\nFor readers seeking a practical path to evaluate durability, this chapter underscores the importance of looking beyond initial price and perceived ruggedness. Real-world durability emerges when a storage system is designed to perform consistently across a spectrum of conditions—the sort of conditions that are the norm rather than the exception in commercial trucking and field service. Consider how a box handles repeated daily openings, exposure to rain, and the rough handling associated with frequent loading and unloading. Consider also how the installation method and the choice between steel or aluminum construction influence long-term maintenance costs, payload efficiency, and the vehicle’s resale value. The durability story is, in essence, a narrative about predictability and resilience: predictability in what the box can hold, and resilience in its ability to stay functional, secure, and ready for action over time.\n\nAs you move through this chapter, keep in mind how Merritt’s design decisions translate into operational utility. The focus on strength, weather protection, secure mounting, and space optimization reflects a broader engineering principle: durability is a feature that compounds value. A robust storage system reduces the cognitive and logistical load on technicians and fleet managers alike, enabling faster response times and better workflow, which in turn bolsters customer satisfaction and competitiveness in a crowded market. In the end, the durable box is not just a container; it is a strategic element of an operation’s reliability, a quiet partner that supports every mile, every service call, and every shipment beneath a demanding sun or a heavy downpour.\n\nFor those who want to connect the durability narrative back to practical specifications, the official product detailing and confirmation of performance can be found through Merritt’s product pages. These resources provide dimensions, certifications, and installation guidance that complement the experiential account described here. To explore further into the official specifications, see the deep-dive resource: https://www.merritttruckbox.com/products/heavy-duty-site-box. This external reference anchors the discussion in verifiable, standards-aligned data and supports fleet decision-makers in assembling a toolbox that matches their operational realities, even as they scale across multiple trucks or service routes.

Final thoughts

Merritt truck boxes represent an invaluable asset for business owners seeking optimal storage solutions in their vehicles. The blend of functionality, versatility, and robust construction allows these truck boxes to meet various demands across different industries. By investing in high-quality Merritt truck boxes, businesses can enhance their efficiency, organization, and overall operation workflow. Prioritize your investment today for a more streamlined tomorrow.