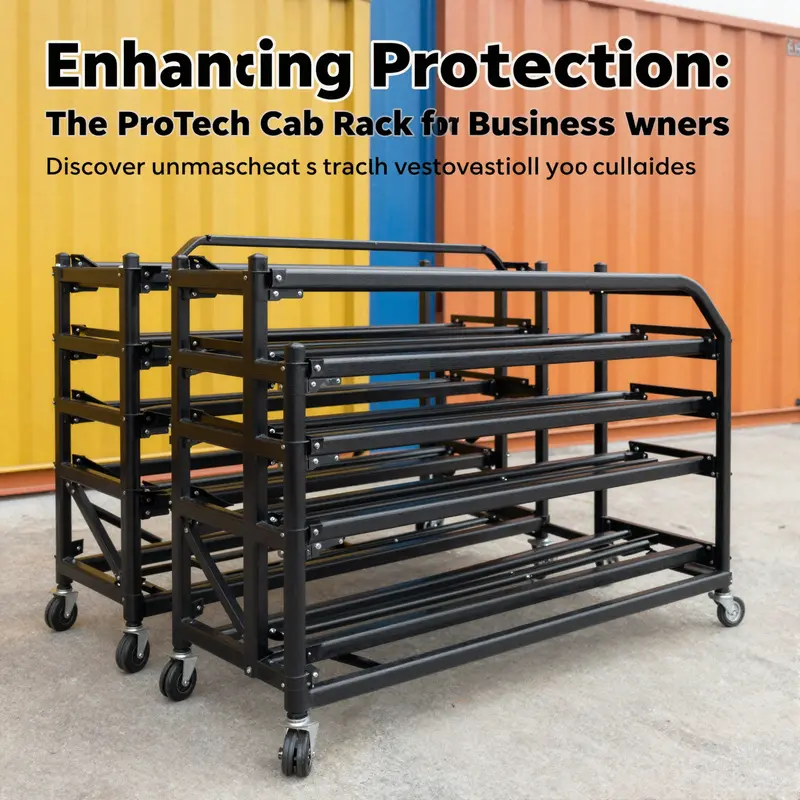

In an era where safeguarding valuable equipment during transport is paramount for businesses, the ProTech Cab Rack stands out as an optimal solution. This heavy-duty transport case, crafted by ProTech (Guangdong) Co., Ltd., is designed to withstand extreme conditions, ensuring your rack-mounted equipment remains safe. This article delves into the construction materials and durability of ProTech Cab Racks, their innovative design features and functionalities, applications across various professional fields, customization capabilities, and market positioning, showcasing why they are an essential investment for business owners.

Durability through Materials and Design: Cab Rack Performance

A durable cab rack starts with material choice and a design that distributes load evenly across rails and brackets.

A steel backbone is common for critical load paths because of high strength and the ability to receive reliable corrosion protection coatings.

Where weight matters, engineers blend high-strength alloys or composites to reduce mass while preserving stiffness.

A well-executed assembly – with proper fasteners, anti-vibration features, and correct torque – maintains alignment and performance under vibration and temperature cycles.

Regular inspection and maintenance of coatings, fasteners, and mounting interfaces are essential to sustaining reliability across years of service.

ProTech Cab Rack: Rugged Mobility and Precision Protection for Audio Gear

When professionals transport sensitive audio gear, every mile and every weather condition tests the margin between reliable performance and costly downtime. The ProTech Cab Rack answers this test with a design philosophy that blends rugged protection with portable precision. Its core idea is straightforward: create a transport solution that can handle the harsh realities of road life without turning every move into a two-person ordeal. The result is a rack system that feels purposeful from first touch to last placement, a unit that respects both the gear it carries and the technician who relies on it.

A defining choice in its construction is the use of a high-strength aluminum alloy. This material brings a strength-to-weight advantage that steel cannot match, without compromising the rigidity needed to keep rack-mounted equipment steady through vibrations and jolts. Aluminum’s lighter weight reduces fatigue for the operator and lowers the energy required to maneuver the unit between venues. Yet the design does not sacrifice durability; the alloy retains sufficient stiffness to resist bending and flex under load, so the equipment inside remains aligned and protected during transit. This balance between resilience and portability is essential when gear rests on the rack’s rails through long road days, sudden stops, or uneven loading at a venue.

The rack rails themselves are a crucial element of stability. Front and rear dual-sided steel rails provide a balanced mounting framework that supports depth ranges from 450 mm to 480 mm. This dual-sided approach means gear can be mounted from either end, a flexibility that proves invaluable when a configuration needs quick swaps or rearrangements in the middle of a tour. The depth window aligns with a broad set of standard rack-mounted devices, from compact preamps to larger console processors, enabling technicians to plan ahead and pack with confidence. With the rails in place, the equipment becomes a single, cohesive unit that travels as one rather than as a collection of loose components. The rails’ precision fit also helps curb internal movement, which translates into quieter travel and less wear over repeated load-ins and load-outs.

Handling the rack is made approachable for solo operators through heavy-duty flush-mount handles. These handles stay unobtrusive when not in use, yet offer a secure grip when lifting or tipping the unit onto wheels, a cart, or a dolly. The flush-mount design reduces snag points and keeps the exterior clean, a practical feature when negotiating tight backstage spaces or cramped loading bays. The goal is to empower one person to maneuver the entire transport unit with predictable control, reducing the risk of dropped gear or misaligned seating. In live settings, where time is money and precision matters, such ergonomic details can determine whether a performance starts on time.

Another standout characteristic is the chassis’s stacking capability, grounded in an interlocking rib structure. This ribbing locks racks together securely, enabling multiple units to be stacked during transport or storage without relying on loose straps or fragile bracing. The result is a space-saving, transport-optimized footprint that simplifies the logistics of large shows or multi-rack setups. When stacked, each unit remains stable, reducing the chance of shifting during transit and protecting the delicate front panels and mounted devices inside from unintended contact. The interlocking design also streamlines inventory management, letting crews load, unload, and store gear with a rhythm that mirrors the tempo of a show schedule.

Protection goes beyond the outer shell. The ProTech Cab Rack is engineered to withstand the unpredictability of real-world environments. Sealing technology delivers a high-performance watertight solution rated IP67, guarding against water intrusion and dust ingress. The IP67 rating indicates complete immersion protection for a limited depth and duration, a standard that matters when trucks splash through rain, when venues endure sudden weather changes, or when gear is staged in dusty outdoor areas between sets. The combination of watertight gaskets and concealed latches ensures the case remains tightly closed even under temperature swings and the vibrations of transport. In practice, this means gear such as mixers, amplifiers, and audio processors can stay ferried between gigs without a constant preflight check for moisture or grit.

Material quality underpins every protective claim. The Cab Rack leverages 100% brand-new materials and patented technology to guarantee high reliability. This emphasis on fresh, controlled compositions helps ensure predictable performance over time, a crucial factor when technicians must rely on gear night after night. The design also prioritizes impact resistance, a must-have when cases are tossed onto loading docks, slid across stage floors, or gently bumped against trailers. The robust exterior, combined with snug interior accommodation, minimizes the risk of damage to sensitive electronics and preserves the integrity of connectors, sockets, and interfaces that frequently govern sound quality.

In practical terms, the Cab Rack’s features translate into meaningful operational advantages. First, its dual-rail depth flexibility accommodates a wide range of equipment without forcing technicians to choose between compactness and capacity. Second, the stacking capability makes it feasible to stage an entire rack system in a single, organized stack, which speeds up setup and teardown during gigs. Third, the accessibility of the handles and the overall balance of the unit support a one-person workflow, even when a rack is loaded with heavy devices. Fourth, the sealing system and rugged construction offer peace of mind when touring in harsh climates or through long freight legs, reducing the likelihood of moisture-related failures in critical gear.

Professionals who depend on reliable transport solutions will appreciate how the Cab Rack is designed with real-world workflows in mind. Musicians rely on consistent performance across stages with varying environmental conditions; sound engineers require quick access to gear during rehearsals and live sessions; touring technicians need a solution that can endure rough handling without compromising equipment safety. In these contexts, the rack’s combination of lightweight alloy construction, robust rails, ergonomic handling, and modular stacking supports a workflow that keeps pace with demanding schedules. The system’s adaptability also lends itself to a variety of configurations, helping crews tailor setups to venues with different backstage footprints or rigging constraints. This adaptability is not an afterthought but a core element of the design philosophy, ensuring the cab rack remains a reliable backbone across diverse touring ecosystems.

The pursuit of reliability extends into workflow considerations beyond the hardware. Customization options are mentioned in the broader ProTech offering, underlining a willingness to tailor enclosures and racks to specific workflows, cable management schemes, or spatial constraints. This flexibility matters when gear families evolve or when a tour’s equipment list expands. In practice, a crew might adjust rack depths, add discreet cable channels, or reorganize front-to-rear mounting strategies to streamline the transportation of new devices without reconstructing the entire system. Such adaptability helps protect a technician’s investment over multiple tours and evolving production needs. For professionals seeking to expand or refine their rack infrastructure, this kind of customization can translate into measurable time savings and a lower risk profile during live events.

In addition to the functional advantages, the Cab Rack also embodies a broader principle of design for reliability. The integration of aluminum alloy construction with steel rails and high-integrity seals reflects a synthesis of materials science and user-centric engineering. The result is a transport solution that remains practical in daily use, even as it defies the wear and tear of touring life. Where a heavy, rigid steel box might compromise mobility, the Cab Rack demonstrates that a lighter, intelligently engineered system can carry the same, if not greater, protective burden. Its emphasis on stackability, ease of handling, and robust protection makes it a compelling choice for professionals who treat gear as a critical asset rather than a disposable tool.

For readers who want a deeper look at related rugged enclosures or to compare additional protective housings, the broader suite of ProTech offerings includes related options that share a common language of durability and practicality. To explore one such family, you can learn about ProTech Boxes. This resource provides a wider perspective on how ProTech tackles enclosure design across different applications, offering insights that complement the Cab Rack’s specialized approach. ProTech Boxes.

As the landscape of live sound and field electronics continues to demand reliability, portability, and modularity, the ProTech Cab Rack stands out as a cohesive response. It balances the weight of daily use with the strength required to safeguard valuable gear, ensuring that performance and transport move in harmony rather than at cross purposes. The design choices—aluminum alloy for the chassis, dual-sided rails for mounting versatility, flush handles for ease of one-person handling, an interlocking rib system for efficient stacking, and IP67 sealing for weather and dust protection—create a transport system that not only protects gear but also respects the time and expertise of the technicians who depend on it. In the end, the Cab Rack is more than a container; it is a carefully engineered workflow facilitator, a trusted partner in the demanding environments where music, sound engineering, and live performance come to life. External references and a broader product ecosystem reinforce this narrative, reminding professionals that durability and thoughtful design can travel as far as the gear itself.

External reference: https://en.wikipedia.org/wiki/IP_code

Rugged Cab Rack Solutions: Safeguarding Sound Gear and Server Infrastructure

Across mobile studios, touring performances, broadcasting suites, and increasingly compact data centers, cab racks have evolved from simple containers to highly engineered platforms that protect, organize, and accelerate the work of technicians. At their core, these systems combine rugged construction with modular versatility, delivering reliability where equipment is most vulnerable: during transport, setup, and continuous operation. The best designs acknowledge three hard truths. First, sensitive electronic gear hates moisture, dust, and the shock of movement. Second, space is never unlimited, especially on a tour or in a crowded data hall, so every inch of rack real estate must be used efficiently without compromising accessibility. Third, technicians need quick, repeatable workflows. A cab rack that meets these demands becomes not just a box, but a mobile workstation that preserves the integrity of the gear while streamlining the sequence of unpack, connect, adjust, and power up.

In practice, the strongest cab racks are crafted from materials and with manufacturing methods that balance stiffness, impact resistance, and weight. Injection-molded shells can yield a seamless enclosure with integrated seals and latching systems that minimize gaps where moisture or dust might intrude. A well-engineered lid or lid alternative locks securely yet remains operable with gloves on, ensuring that live sound setups or on-site data operations aren’t slowed by hardware constraints. The use of 100% new materials and proprietary formulations often accompanies a design that resists fatigue after repeated openings, closures, and rough handling. A robust rack also anticipates the demands of transport. Concealed latches, for example, reduce snag hazards during stacking or rolling, while the exterior ribbing creates a stable, interlocking frame when multiple cases are stacked for storage or shipping. Such features aren’t cosmetic; they translate into tangible gains in reliability and speed, the very traits that keep a show on time or a data center responsive to incidents and maintenance.

Beyond the shell, the internal architecture of a cab rack frequently centers on dual-layer rails or cantilevered mounting options that accommodate a range of equipment depths and configurations. Dual-layer rails offer front and rear access for installations, allowing technicians to drive cables from either end without compromising the footprint of the equipment inside. In practice, a depth range of roughly 450 to 480 millimeters covers a wide spectrum of audio interfaces, preamps, field processors, and small server blades or network devices. This versatility matters on tour where a single rack may need to house multiple signal paths or on the data floor where high-density gear must be organized without entangling power and data cables. The internal plan also hinges on strength and stability. Heavy equipment can shift during transit, so rails must resist bending, while the overall chassis should resist torsion as the rack is wheeled or bumped in transit. Integrated handles are not mere convenience; they reduce the risk of accidental drops and help technicians maneuver gear through tight spaces with fewer人员 and less fatigue. Optional wheels can convert a stationary rack into a mobile workstation, a useful feature for on-site venues and temporary data deployments.

Yet a truly capable cab rack does not stop at raw resistance and rail strength. Effective cable management becomes part of the design language, not an afterthought. The most practical racks provide channelized pathways or cable-friendly channels that guide power, video, and data lines where they won’t be crushed or overstretched. A well-thought-out design can also contribute to thermal performance. In dense environments, air needs to circulate around the gear to prevent heat buildup that can degrade performance or shorten component lifespans. Strategic venting, appropriate internal spacing, and materials with favorable heat dissipation characteristics help maintain stable operating temperatures even when the rack is packed with active devices. These considerations matter equally in a live sound context, where a mixer, multi-effects processors, and audio interfaces must respond to dynamic workloads, and in a data-center-like setting, where dense server configurations demand dependable airflow management.

Applications in professional sound environments testify to the practical benefits of these features. Recording studios and live venues rely on a single, well-organized chassis to hold signal chains, effects, and monitoring equipment. When a setup includes multiple racks, a logical arrangement reduces the need for repeated cabling rewiring, accelerates stage changes, and lowers the likelihood of human error during critical transitions. A rack with modular shelves and accessible ends enables technicians to remove or swap components quickly, which is essential in sessions where time is money and the difference between a perfect take and a missed cue can hinge on how fast a piece of gear can be swapped or re-routed. The ability to mount gear from both the front and the rear opens up possibilities for flexible arrangements, supporting both compact studio desks and larger, double-sided configurations that professionals may deploy to optimize visibility and reach for touchpoints, meters, and control surfaces. A wide field of view, a phrase heard in similar systems, grows from the combination of sturdy construction and intelligent interior layout. When technicians can see and reach what they need without wrestling cables or contorting around racks, the risk of mishandling gear declines and uptime improves across the board.

Meanwhile, the same cab rack concept translates to data center and network room scenarios where efficiency, scalability, and reliability are prized. In these environments, the rack’s organization is not just about tidiness; it determines how quickly administrators can access failed components, swap out drives, or reroute network paths after a fault. The robust rails and optional wheels can help teams reconfigure racks during deployment or maintenance without disconnecting critical services for long periods. In mature facilities, a disciplined rack approach supports better cable hygiene, which translates into lower heat, more predictable airflow, and easier fault isolation. An intelligent system design that manages the interface between hardware, software, and mechanical structures is equally relevant here. Teams increasingly demand solutions that support remote monitoring and, where appropriate, wireless status updates, enabling operators to keep an eye on temperature, fan speed, door closures, and vibration indicators from a central console.

Customization also sits at the heart of a successful cab rack strategy. The ability to tailor a system to fit particular equipment layouts—whether through adjustable shelves, removable panels, or non-standard depths—helps organizations avoid awkward workarounds. In practice, customization supports a broader spectrum of use cases: selective pallet racks in a warehouse, wire mesh containers for peripherals, or tool trolleys that ride alongside the main chassis for rapid field servicing. The capability to tailor the external dimensions and internal mounting options ensures that a single rack family can address both mobile, on-the-road needs and stationary, climate-controlled installations. Of course, such customization must balance cost and lead time. The best manufacturers balance aggressive production throughput with flexible manufacturing practices, offering scalable production that can accommodate large orders while still delivering bespoke configurations when required. This balance is essential for facilities ranging from freelance studios to enterprise-scale data centers where demand for secure, high-density storage solutions continues to rise.

As the market for robust cab rack systems grows, it’s clear that the value extends beyond the shelf. A well-designed rack becomes part of a broader workflow, supporting faster setup, safer transportation, and easier maintenance. It reduces the cognitive load on technicians who must juggle equipment, cables, and environmental controls in challenging environments. It also provides engineers and operators with a dependable platform on which to standardize procedures, train new personnel, and document configurations for future audits. The result is not merely a container for equipment but a modular, resilient backbone that underpins reliable performance in both sound and data-centric environments. This perspective helps explain why the industry places such emphasis on sealing integrity, shock resistance, and seamless front-rear access as core features—attributes that directly correlate with uptime, asset longevity, and operational efficiency across the board.

For readers seeking a deeper dive into the precise specifications, it helps to consult official, detailed resources that outline the exact materials, seal ratings, rail tolerances, and mounting standards. While particular product names and brands are not the focus here, understanding the general capabilities—sealed enclosures, rugged durability, modular rails, and configurable depth ranges—provides a solid foundation for evaluating options in the field. Practical tests and case studies often highlight real-world results, including how these racks perform under repeated travel, how they withstand environmental exposure on tours, and how they manage power distribution and airflow in busy data environments. In every case, the guiding principle remains constant: design for resilience, flexibility, and ease of use so that technicians can concentrate on their core work rather than wrestling with storage hardware.

External reference: https://www.protech.com/products/cab-rack

null

null

Fortifying the Rack: ProTech Cab Racks, Market Leadership, and the Craft of Protective Engineering

In the world of professionals who move heavy, delicate gear across climates and continents, the cab rack is more than a case. It is a shield that travels with equipment. The market for protective enclosures rests on trust, durability, and the ability to guard electronics under pressure. Within this landscape, ProTech positions itself as a premium maker of heavy duty, injection molded rack cases designed to endure the rigors of touring, live events, and data center logistics. Its strategy blends advanced materials, sealed engineering, and in-house design talent to deliver more than a container; it offers a portable micro-environment for electronics.

ProTech’s market position rests on credible signals of quality and reliability. The company pursues a high end segment by emphasizing IP67 sealing, multi layer rails, and a structure designed to withstand vibrations, drops, and harsh handling. On the commercial side, it has built an international footprint that extends beyond regional customers, with trust indicators on major B2B platforms reflecting a disciplined commitment to quality. The production machinery behind this positioning is robust, capable of manufacturing tens of thousands of units each month, indicating that the brand can serve both specialized projects and larger procurement programs, with lead times that satisfy demanding schedules.

The competitive advantages are anchored in proprietary materials, engineering discipline, and a logistics mindset. The cases bodies arise from a patented formula using 100 percent new material produced through injection molding. This is not standard plastic; it is a formula tuned for dimensional stability, impact resistance, and long term ruggedness. The sealing system is another pillar. An IP67 rated seal, achieved via built in waterproof gaskets and flush latches, promises protection against immersion and complete dust exclusion. In practice, this level of protection matters when gear is moved in variable weather, on boats, in dusty venues, or through stormy transit routes. The combination of a sturdy exterior and reinforced interior rails creates a stable backbone for rack equipment, with front and rear mounting rails that accommodate typical depths, while maintaining balance during movement.

The attention to structural integrity extends to how the racks themselves integrate with the case. Interlocking ribs on the outer shell enable secure stacking during storage and shipment, reducing the risk of shifting or deformation in transit. The internal rails are not merely slots; they are an engineered subsystem that supports heavy gear while preserving thermal and mechanical stability. The depth specifications allow for a wide range of equipment to be mounted from either front or rear end, which enhances serviceability and minimizes the chance of misalignment during loading. For users who rely on quick setup and tear down, the flush mounted handles provide a low profile grip that reduces snagging when cases are stacked on a truck bed or moved through backstage corridors. Optional wheels further extend mobility, turning a heavy shell into a portable workstation suited to touring rigs or temporary data hubs.

A key driver of ProTech’s market advantage is the company’s in-house design and engineering capability. An internal team can translate customer needs into tangible, resilient products with rapid iteration. Customization becomes a competitive lever rather than a friction point, enabling configurations that match exact rack depths, mounting patterns, and accessory arrays of professional gear. This capability matters in practice because professional users rarely want off the shelf compromises; they want a system that integrates seamlessly with their existing racks, cables, and interfaces. The result is a suite of solutions that behave as part of a protected ecosystem, not as a detached box that merely carries equipment. When these capabilities are combined with a disciplined supply chain and scalable production, the brand can offer reliable volumes with predictable delivery windows, even for complex orders.

From the user perspective, the value proposition centers on protection, reliability, and operational efficiency. In live performance contexts, sudden weather shifts, mechanical shocks, and transport jostling can threaten sensitive audio processors, amplifiers, and mixers. In data center logistics, portability and ruggedness translate into faster deployment and reduced downtime. The rack case thus becomes a portable, controlled environment that preserves calibration, protects sensitive electronics from moisture and dust, and minimizes vibration induced wear. The design choices—dual layer steel rack rails, compatibility with standard equipment footprints, and safe stacking geometry—reflect a deep understanding of how professionals actually move gear through real world workflows. The result is not merely a container but a modular backbone that supports a broader litany of workflows, from stage to studio to server room.

Equally important is the brand’s capacity to scale. The production capability to meet tens of thousands of units monthly demonstrates a maturity in manufacturing operations. It signals the ability to support recurring procurement programs and high volume campaigns without sacrificing consistency. In a market where lead times can be a differentiator, the capacity to deliver reliably becomes a form of competitive advantage in its own right. This scale, coupled with in-house design, underpins a vertical integration model that reduces dependency on outside suppliers for critical components and allows for tighter tolerances and tighter control over the final fit. The interplay between material science, mechanical design, and manufacturing discipline yields a family of products that behave like a complete system rather than disparate parts.

The market implications extend beyond technical performance. For professional buyers, the decision calculus weighs not just the protection features but also total cost of ownership, serviceability, and the predictability of supply. A premium protective solution that reduces risk of gear damage, minimizes downtime, and improves logistics efficiency can yield savings that exceed the upfront price. This is especially true in professional audio and IT environments where a single mishap can ripple into costly downtime. The ability to customize equipment footprints, rails, and lids translates into a more streamlined procurement process where a client can standardize on a small family of cases across multiple locations or tours. In this sense, the cab rack becomes part of a longer arc of reliability in a professional venue or data centric operation.

Within the ecosystem of protective enclosures, the premium line aligns with the broader community of solutions that prioritize ruggedness, modularity, and ease of use. The emphasis on front and rear mounting rails, a two layer internal rack framework, and a stack ready external shell signals a complete approach to transport safety. The brand’s emphasis on a dedicated design team means it can respond quickly to evolving standards, changing equipment footprints, and new accessory options. A buyer considering this category would not merely be purchasing a box; they would be acquiring a portable rack system that preserves performance, reduces maintenance, and enhances on site efficiency. This is the essence of the market position: a durable, adaptable platform that can flex with the demands of professionals who move gear for a living.

To connect with the broader ecosystem, the company demonstrates its willingness to integrate with other industry resources and distribution channels. A robust internal portfolio is complemented by content and guidance that speaks to the practical realities of rack transport. For readers seeking deeper context on protective solutions, a related resource within the industry helps illuminate the standards that govern sealing and ingress protection, including the kind of durability front line gear requires. To explore related packaging components and the ways they support rack based equipment, see the ProTech boxes resource. protech-boxes

In summary, ProTech cab racks sit at a strategic crossroads of engineering rigor, customer centric customization, and scalable operations. They deliver a protective environment for high value equipment, while also providing predictable delivery and integration with existing rack ecosystems. The result is a compelling value proposition for professionals who demand both protection and performance as they move gear through demanding environments. The company’s vertical integration, proprietary materials, and in house design capability create a durable advantage that is difficult for competitors to replicate. By combining strong sealing, robust rails, and practical features like stackable casings and flush handles, the brand positions itself not merely as a supplier of cases but as a trusted partner in moving critical technology. This combination of engineering discipline, market reach, and operational scale helps explain why the cab rack remains a pivotal element in professional workflows, where equipment protection and logistics efficiency are equally valued.

External resource: IP Code overview for sealing and ingress protection standards, which helps illuminate the technical basis behind IP67 performance and the expectations customers have for rugged transport solutions. https://en.wikipedia.org/wiki/IP_Code

Final thoughts

The ProTech Cab Rack represents much more than a transport case; it combines advanced materials, innovative design, and extensive customization options to meet the needs of various industries. From the music and audio sectors to data centers, the security and reliability of this product provide peace of mind for business owners. Its market position is bolstered by its capabilities to support a wide variety of equipment while ensuring quick production and delivery, marking it as an invaluable asset for those committed to protecting their investments during transit.