The Tesla Cybertruck Ladder Rack stands as a beacon of utility for business owners seeking innovative transportation solutions. Designed to seamlessly integrate with the Cybertruck’s structure, this accessory greatly enhances your cargo capacity and organization. As we delve into the chapters, we will explore the robust design and seamless installation, assess the load capacity and materials used, examine compatible accessories, and guide you through the installation process. Understanding these facets is crucial for business owners eager to optimize their use of the Cybertruck for various tasks, from construction to outdoor adventures.

Integrated Ladder Rack: Design, Integration, and Utility on the Angular Workhorse

When a pickup is conceived as a versatile work platform, its utility hinges on how well every accessory integrates with the vehicle’s core design. The built-in ladder rack that runs along the bed’s side rails exemplifies a design philosophy that treats utility as an integral, not adjunct, part of the machine. This approach ensures that loading long items—ladders, long pipes, or oversized materials—feels almost effortless rather than a fitment project. The rack is not an aftermarket add-on slapped onto a pallet of steel. It is a factory-integrated feature that borrows from the same design language and structural intent that defines the rest of the vehicle: a commitment to strength, modular capability, and a stance that remains true to the vehicle’s angular, futurist silhouette. The result is a platform that can carry a 200-pound (90-kilogram) payload in a way that feels as seamless as it is practical, combining robust utility with a sense of permanence that reflects the vehicle’s engineering ethos.

From a materials perspective, the ladder rack is designed to endure the rigors of daily work and the harsher conditions of off-road use. It is crafted from high-strength, cold-rolled stainless steel—the same material family that forms the body and critical chassis components—so corrosion resistance, surface durability, and long-term resilience are built into the core. The rack’s finish is powder-coated, a detail that is more than cosmetic. The coating protects the structural members from scratches and chips that can lead to wear over time, while also shielding edges from the abrasiveness of carried gear. This combination of material choice and finish aligns with the broader aim of creating a platform that can endure long-term exposure to sun, rain, mud, and road grime without losing its integrity or appearance.

One of the most striking aspects of this design is its seamless integration with the truck’s side rails. Rather than a separate module that hangs off the bed, the ladder rack is an extension of the bed’s structural framework. This integration matters in several ways. First, it preserves the vehicle’s aerodynamics and maintains the bed’s clean profile, an important consideration for a vehicle that blends utility with a distinctive aesthetic. Second, the alignment with the side rails reinforces rigidity; the rack shares mounting points with the bed that were engineered to handle the dynamic loads associated with heavy items. The result is a system that feels solid in use, with no noticeable flex or rattle even when a ladder, long pipe, or other long item is extended along the rack’s length.

The design language continues in the rack’s modular philosophy. This is not a single-purpose mounting apparatus but a flexible platform ready to embrace a range of accessories. The rack employs standardized mounting points and built-in T-slots, enabling a spectrum of configurations that include roof racks, cargo boxes, or additional storage systems. The modularity is purposeful: it gives owners the freedom to tailor the vehicle to specific tasks without stepping outside the vehicle’s core structure. A ladder, a bike, or a long piece of lumber can be secured in a way that makes sense for the job at hand, and then swapped out for a toolbox or a roof-mounted container when the project changes. In practice, this means you can plan a weekend project, with a ladder strapped high and a toolbox perched nearby, then reconfigure the setup for a camping trip where organized storage and ready access to gear are paramount.

The rack’s integration with the vehicle’s electrical system is equally deliberate. Official accessory kits offer options that extend beyond static support to functional lighting and power. Integrated LED lighting and wiring harnesses are engineered to work with the truck’s electrical architecture, enabling features such as running lights along the rack or power outlets that can be accessed without unloading gear. This level of electrical integration speaks to a broader design principle: accessories should enhance convenience without requiring a separate, makeshift wiring harness or a DIY workaround. When a kit is installed, the lighting aligns with the vehicle’s control logic, which helps maintain a clean electrical footprint and minimizes potential compatibility issues that can plague aftermarket add-ons.

From an ergonomic standpoint, the ladder rack is designed with the user in mind. The built-in mounting points and the rack’s position relative to the bed height are calibrated to make loading and loading-related tasks more predictable and less physically taxing. The rack’s height is not arbitrary; it is tuned to provide a secure ladder contact point that minimizes vibration and movement when the vehicle is in motion. This is especially important on rough terrain where loose items can shift, creating noise or damage. The design’s emphasis on stability extends to how the rack interacts with long items: the profile is shaped to reduce snag points, and the attachment interfaces are engineered to distribute load evenly along the rail system. In practical terms, a ladder slides into place with confidence and remains aligned as you secure straps or clamps, reducing the time and effort required to prepare for a job site.

The design also respects the vehicle’s signature lines. The ladder rack does not erase the vehicle’s angular aesthetic; it honors it. The rack’s geometry mirrors the sharp, factory-feel geometry that characterizes the bed and its rails, creating a coherent visual language across the entire silhouette. This attention to form as well as function matters; a rack that looks like an afterthought can undermine the perceived value of a well-executed utility feature. Instead, the integrated rack reads as a continuation of the vehicle’s engineering story—an accessory that answers practical needs while staying true to the machine’s visual and structural identity.

The official approach to kit availability underscores a broader industry trend toward direct-to-consumer customization. The ladder rack is offered as part of certified accessory packages that are designed to be installed quickly and without compromising the truck’s electrical or structural systems. Owners can select configurations that align with the most common work scenarios, whether that means prioritizing additional storage options, lighting, or mounting flexibility for future upgrades. The emphasis on certified kits reinforces the idea that a utility platform should be reliable from day one and easy to adapt as needs evolve. Rather than a modular assemblage of parts that require field modification, this system is conceived as a cohesive expansion of the base vehicle, with instructions and compatibility checks integrated into the purchase flow. It’s a practical embodiment of a broader philosophy: treat the vehicle as a customizable work platform that can be configured to meet the demands of varied tasks right from the showroom floor.

In practice, the ladder rack’s everyday use reveals its strengths in a straightforward way. For tradespeople and outdoor enthusiasts alike, the ability to secure ladders, bikes, or long items without drilling into the bed reduces the risk of voiding warranties or compromising the vehicle’s structural integrity. The integrated rack preserves the bed’s original geometry and load path, so the vehicle’s core strength remains intact. The load rating of 200 pounds (90 kilograms) is not a marketing number but a practical limit that reflects careful consideration of how loads are distributed along the rails and how clamps, tie-downs, and contact points interface with the rack’s framework. This attention to real-world use matters when planning a day’s work, a backcountry expedition, or a service call that requires lugging bulky gear in a compact, capable package.

The notion of customization also surfaces in the way the rack interacts with other gear and systems. The T-slots expose a universal language of attachment that makes it easier to bolt on additional components, from toolbox placements to auxiliary roof racks. This approach reduces the friction typically associated with adding new equipment—no one wants to wrestle with incompatible clamps or misaligned holes. The system is built around predictability and repeatability, enabling a workflow where gear can be reconfigured quickly as the project evolves. It’s a tangible demonstration of how thoughtful integration can elevate a vehicle from a capable transportation solution to a dependable work platform that grows with the owner’s ambitions.

For readers exploring related modular and utility-focused options, a concise route into deeper discussions of compatible configurations can be found in targeted guides about roof-mounted gear. In particular, the broader category of roof racks—presented in dedicated projects and how-to resources—offers context for how the ladder rack can synergize with other storage solutions. See the Roof Racks guide for a closer look at how modular frameworks are designed to work in concert with built-in rails and standard mounting points. Roof Racks.

Together, these design and integration decisions create a utility platform that respects the vehicle’s intrinsic strengths while expanding its practical reach. The ladder rack becomes more than a way to carry a ladder; it is a thoughtful extension of the work ethos the vehicle embodies. It is a statement about how a modern utility vehicle can balance rugged capability with sophisticated engineering, delivering a system that is robust, adaptable, and easy to live with day after day. The result is a more capable workhorse that can be tailored to a wide range of tasks without compromising the vehicle’s core performance, warranty protections, or aesthetic integrity. In the end, that combination—structural integration, modular flexibility, and seamless electrical compatibility—defines a ladder rack that truly earns its keep on the angular, all-purpose platform it accompanies. For those weighing upgrades, the key consideration is simple: will the accessory feel like a natural extension of the vehicle, rather than an add-on that needs constant babysitting? The answer, when the rack is viewed through the lens of design, engineering, and real-world use, leans toward a confident yes.

External reference: https://www.tesla.com/cybertruck/accessories

Guarded Utility: Understanding the Load Limits, Materials, and Real-World Use of the Cybertruck Ladder Rack

The Cybertruck ladder rack stands as a quiet workhorse in the fleet of factory-enabled accessories, a deliberate design choice that widens the vehicle’s utility without forcing owners into permanent alterations. It sits along the bedsides in a way that respects the truck’s signature geometry, yet speaks to the practical demands of everyday use. The system is anchored to the Cybertruck’s built-in mounting points, a feature that lets it install cleanly and reversibly, avoiding any drilling or invasive modifications. Its construction leans into the same aluminum-centric ethos that defines the vehicle itself: lightweight yet strong, capable of withstanding the rigors of open-air work sites and rugged backroads alike. The rack is crafted from powder-coated aluminum, a finish that guards against the elements while preserving the polished, industrial silhouette of the truck. The towers that support the crossbars are die-cast aluminum, precisely engineered to hold long loads securely in place. This combination of materials serves a dual purpose: it keeps weight down, preserving efficiency and handling, while delivering the corrosion resistance that matters when gear is exposed to rain, dust, grit, and road spray. A locking mechanism and a quick-release feature further enhance practical usability. The lock deters casual theft or shifting during transit, while the quick-release system makes it straightforward to load and unload heavy items without wrestling with stubborn clamps. The rack’s geometry is inherently compatible with T-slots, which opens the door to a modular ecosystem where toolboxes, auxiliary racks, or overlanding gear can be attached with relative ease. This is not merely a staging area for tools; it is a flexible platform that expands the Cybertruck’s cargo envelope while keeping the vehicle’s balance, efficiency, and style intact. The value of this hardware rests not only in what it can carry, but in how reliably it can carry it day after day, season after season, with a maintenance routine that is straightforward and forgiving for owners who use their trucks as practical work tools as well as everyday transport. The design is not about maximizing sheer bulk but about delivering predictable performance under real-world conditions, where loads shift, stops occur, and surfaces vary from smooth highways to unpaved byways. The result is a system that, at its core, embraces the cybernetic philosophy of the Cybertruck itself: a balance between rugged capability and clean, purposeful engineering.

At the heart of the ladder rack is a value proposition that centers on load practicality rather than brute force. The system is rated to carry up to 200 pounds, or roughly 90 kilograms, directly on the rack. This figure is a ceiling for the rack’s own surface area, and it reflects what the aluminum structure and mounting points can support in normal conditions. It is well suited for securing lightweight cargo such as bicycles, camping equipment, or small luggage—items that benefit from a high, stable platform without introducing excessive mass. It is important to understand that this rating is independent of the Cybertruck’s towing capacity. The rack’s load limit pertains to what sits on the rack itself, not to the vehicle’s overall hauling capability. In other words, the ladder rack is a load-bearing accessory, not a replacement for the vehicle’s drivetrain’s capacity to haul or tow heavy loads. This distinction becomes crucial when considering long trips or multi-day overland plans where every pound matters. The factory-oriented philosophy behind the rack is to provide utility without compromising safety or performance. It leverages the truck’s own mounting infrastructure and the strength of aluminum to deliver a secure, resilient platform that integrates with the truck’s geometry. It does not demand contortions in loading strategies or elaborate protective measures beyond the usual tie-down practices that ensure stability during transit. The emphasis is on predictable behavior: loads that are evenly distributed, secured with reliable straps or bungee mechanisms, and checked before departure to prevent unwanted movement.

The material choices behind the rack reinforce this practical mindset. Powder-coated aluminum is a lightweight yet durable choice that resists corrosion and wear, maintaining a clean appearance even after exposure to road salt, rain, or mud. The die-cast aluminum towers are part of a precise mating system—engineered to align perfectly with the Cybertruck’s mounting points and to hold fast without flexing. This combination matters because rigidity in the mounting interface translates into steadier loads and less wear on the load-fastening hardware itself. The locking mechanism adds a layer of security, deterring tampering or accidental disengagement while the quick-release system keeps loading operations efficient. Together, these features underscore a broader design principle: maximize utility with minimum intrusion. Because the rack relies on existing mounting points and uses non-destructive clamps or fasteners, it preserves the integrity of the bed and its structure, while still offering a robust, load-bearing platform. The emphasis on corrosion resistance and weight savings aligns with the broader material strategy of the Cybertruck, which favors high-strength, lightweight aluminum alloys across critical structural components.

Still, the 200-pound limit is real, and it carries important implications for owners who intend to push the rack toward its upper edge. Unlike the heavy-duty towing capability that a Cybertruck can display—approaching several tons depending on configuration—the ladder rack’s capacity is a discrete constraint tied to the rack itself. The more weight you put on top, the more you must consider how it shifts with acceleration, braking, and rough terrain. This is not a misleading caution; it is a practical guideline that helps maintain stability and vehicle dynamics. In the broader context of vehicle capacity, it’s easy to conflate rack load with towing or overall payload. Yet the rack exists as a long-item carrier and a tool-attachment platform, not as a substitute for proper payload management within the bed or chassis. When the rack carries light cargo, the distribution matters as much as the total weight. A well-balanced load—avoiding all the weight on a single point, using crossbar alignment to distribute weight across the length of the rack, and securing items firmly with straps that can withstand vibration—will yield safer, steadier transport. By contrast, overloading or placing heavy items toward the ends of the rack can introduce leverage effects that the mounting points and the bed rails were not meant to absorb. In this sense, the rack is a precision instrument rather than a bulk carrier.

The broader message about load and usage is reinforced by the vehicle’s own capacity for heavy work. The Cybertruck’s towing specification—up to about 4,990 kilograms in AWD and Beast configurations—demonstrates the vehicle’s potential for substantial heavy lifting when the chassis, powertrain, and suspension are engaged in a coordinated system. The ladder rack, however, sits in a separate lane. It is designed to expand the range of practical cargo without altering the fundamental safety calculus of towing. In real-world terms, that means you can transport ladders, bikes, and camping gear without compromising the core integrity of the truck. Still, the literature and field testing surrounding this component have highlighted an important caveat: extreme vertical pressure applied to the hitch or abrupt, abnormal directional forces can pose risks to the frame when the vehicle is in motion. These anecdotes, while not universal, underscore the principle that high-stress demands placed on any vehicle system—especially under heavy braking, over rough terrain, or during aggressive maneuvers—can propagate through the chassis and the load-bearing members in unexpected ways. The lesson is straightforward: treat the ladder rack as a carefully engineered adjunct, designed for stable, well-distributed loads and routine usage. Avoid straining the system with unusual loading directions or weight beyond its rating, and always secure items with the same diligence you would apply to any high-value tool or piece of equipment.

Material quality, practical load limits, and the rack’s modular potential all point toward a design that respects the long-term needs of outdoor enthusiasts, tradespeople, and adventurers who rely on the Cybertruck as a versatile platform. The rack is not a one-size-fits-all solution; it is a deliberately chosen accessory that complements the truck’s inherent strengths. Its aluminum construction reduces weight and supports efficiency, which is a meaningful consideration for a vehicle that already pushes the envelope in terms of power and aerodynamics. The powder-coated finish, in particular, helps to maintain surface integrity after exposure to moisture, dust, and road spray—conditions that are common across job sites and off-road routes alike. The die-cast towers bring a precision-toolk appropriate rigidity to the interface between rack and vehicle, ensuring that the load remains anchored over time and with varying weather conditions. The locking mechanism lends peace of mind to operators who need to leave gear briefly unattended, while the quick-release feature reduces the effort required to load and unload bulky items. The presence of T-slots on the rack speaks directly to modularity: these channels invite a cascade of accessory options, from toolboxes that slide into position to additional roof racks or specialized overlanding gear that can be mounted without losing the ability to add or remove items as needed. This modularity is not about adding complexity; it is about preserving the integrity of the cargo system while expanding its flexibility to accommodate a wide range of practical needs.

For readers contemplating how to fit this rack into their broader cargo strategy, it’s worth noting the practical implications of installation and maintenance. The installation relies on the Cybertruck’s existing mounting points, a process that is typically reversible and free from drilling. This approach preserves the vehicle’s warranty considerations and makes it possible to revert to stock configuration if desired, a feature that resonates with owner desires for future adaptability. Maintenance is straightforward: check the locking mechanism for smooth operation, inspect for corrosion or wear on the die-cast towers, and ensure that the clamps and fasteners remain tight after initial use and after periods of heavy driving. Regular inspection helps catch minor signs of wear before they become more serious issues, which is especially important given the rough environments many owners encounter. Careful loading, smart weight distribution, and secure tie-down practices all contribute to a safe, dependable cargo solution that remains faithful to the Cybertruck’s ethos of capability without compromising structural integrity.

In the end, the ladder rack is best understood as a targeted enhancement—one that echoes the truck’s own emphasis on robustness and practicality. It offers a clear set of advantages: a high, accessible platform for long items; a lightweight, corrosion-resistant material profile; a locking and quick-release system that makes loading and unloading efficient; and the flexibility provided by integrated T-slots for accessories. Yet it also carries clear boundaries: a defined 200-pound load limit on the rack itself, and the understanding that the vehicle’s powerful towing capacity operates in a different domain. Owners who approach the rack with this mindset will find a well-balanced, dependable companion for everyday use and weekend adventures alike. The real utility of the Cybertruck ladder rack lies not in its ability to haul the heaviest loads, but in its capacity to enable easy access to gear, to neatly organize items for transport, and to do so in a way that respects the vehicle’s core design language and engineering philosophy.

For those seeking a broader context on how these factory-integrated cargo solutions fit into the wider ecosystem of roof-mounted storage and accessory options, a look at related applications can be enlightening. See the Roof Racks guide for a broader perspective on how cargo systems integrate with factory mounting points and the Cybertruck’s geometry, which echoes the same design principles that govern the ladder rack’s installation and use. Roof Racks

External reference: For official specifications and manufacturer guidance, consult the external resource: https://www.tesla.com/support/cybertruck-accessories/ladder-rack

Tall, Tidy, and Trusted: Navigating Ladder Rack Compatibility Within the L-Track System of a Modern All‑Electric Pickup

The ability to carry long, awkward loads—ladders, sheets of insulation, long pipes, or bulky tools—without sacrificing payload integrity has become a maker’s dream for any modern pickup. The ladder rack that integrates with the vehicle’s cargo area does more than provide space; it transforms the way a user interacts with the truck’s core purpose: moving gear from point A to point B with confidence. In this chapter, we explore how such a system negotiates the practical realities of real-world use, how the L‑Track platform supports modularity without permanent modification, and what that means for owners who want a single, adaptable solution that stays true to the vehicle’s geometry and safety margins. The narrative here threads together design intent, mounting philosophy, and the operational realities of weekend projects, pro jobs, and everything in between. It is a story of how a minimal, well‑engineered interface can unlock a broad range of configurations while preserving the truck’s original character and structural integrity.

The foundation of any credible ladder rack solution on a modern all‑electric pickup rests on a simple premise: you want a secure platform that attaches where the vehicle already provides structure, without drilling or compromising the body. The system achieves this by leveraging integrated L‑Track rails that run along the roof and the bed rails. L‑Tracks are standardized, modular, and designed to accept a spectrum of clamps or brackets that slide or hook into place. This arrangement delivers a few core benefits. First, it preserves the factory mounting points and avoids permanent alterations, a consideration that matters not only for warranty and resale value but also for durability in the face of vibration, temperature swings, and road debris. Second, it enables a modular approach to gear—ladders, toolboxes, or other long items can be tethered with adjustable hardware that moves along the track to balance weight and keep center of gravity predictable. Third, the system honors the truck’s angular, industrial aesthetic by providing a rugged, low-profile profile when loads are not in use, rather than a bulky, obstructive add‑on that draws attention away from the vehicle’s design language.

At the heart of the compatibility conversation lies two questions: which ladder racks can work with the L‑Track system, and what does “works” really mean in practice? The first question hinges on whether an accessory is designed to mate with the Cybertruck’s (or, more broadly, the target truck’s) L‑Track hardware. Compatibility is not a guarantee simply by being labeled as a “ladder rack.” It requires that the accessory ships with clamps or mounting hardware that are explicitly rated to engage with the L‑Track rails and the rails’ mounting geometry. Without those clamps, brackets, and sliders, a rack may bolt in theory but fail in use, especially under load and during dynamic maneuvers on rough roads. The second question—what constitutes functional compatibility—extends beyond fit. It encompasses load distribution, ease of adjustment, weather resistance, and the ability to accommodate multiple configurations. A modular system is most valuable when it can be reconfigured to carry a ladder on one trip, then a toolbox and a roof rack assembly on the next, all without reengineering the mounting approach.

From a materials perspective, the most common and reliable ladders rack systems for these platforms are built from durable metals with protective finishes. Aluminum is a frequent choice due to its light weight, corrosion resistance, and sufficient strength for typical ladder lengths and tools. A powder-coated finish further extends life by resisting chipping and oxidation, which is essential for outdoor exposure. The load rating is a practical guidepost. A well‑designed system often targets around 200 pounds (approximately 90 kilograms) for the rack itself, which covers the ladder plus the inevitable tools and brackets that accompany it. This rating is not just a number; it translates into a real-world behavior: a ladder rack that remains stable during acceleration, braking, and terrain undulations. It also hints at the safety headroom engineers built in for dynamic loads when the vehicle is at speed or navigating uneven surfaces. A 200‑lb rating gives a practical envelope for most common ladder and long-item configurations while leaving a margin for misalignment or unexpected gusts, which is especially important for owners who frequently operate in remote or rough environments.

But even with the right materials and a solid load rating, compatibility demands attention to mounting hardware. Here, the L‑Track system shines because it standardizes attachment points and provides a framework within which different brands can operate. The rack must arrive with clamps or brackets specifically designed to engage with the track’s geometry. Substituting generic hardware or using misfit fasteners invites clatter, shifting loads, and, in the worst case, structural damage to the rails or bed. A thoughtful installation approach includes verifying that every clamp seats cleanly in the track channels, that the attachment points align with the rail positions, and that fasteners are rated for expected loads. When properly matched, clamps and brackets translate the track’s modular promise into a secure, rock-solid mounting plane. The result is a rack that behaves as an extension of the truck, not as an add‑on that fights the vehicle’s balance with every turn.

The practical upshot for users is straightforward: if you plan to carry ladders or long gear regularly, you want a system that can be arranged quickly, adjusted without tools, and secured with confidence. This is where the synergy between the rack and the track becomes evident. A T‑slotted interface, which is common in L‑Track implementations, can accept a range of accessories with minimal fuss. It means you can slide a mounting block into the track, lock it with a simple clip or screw, and then attach a ladder cradle or a crossbar with compatible hardware. If you approach the problem with a modular mindset, you can keep the bed free when you don’t need the rack, while still having a clear, repeatable method for converting the space in minutes rather than hours.

Another layer of consideration centers on how the rack integrates with the vehicle’s geometry and the cargo ecosystem. The all‑electric pickup’s chassis and suspension contribute to a certain ride height and stiffness profile. A rack solution needs to respect this framework and avoid introducing a noticeable jog in wind noise or drag that could reduce efficiency or aerodynamics, especially on highway runs with a loaded ladder. A well‑engineered rack stays low and compact when not in use, and when loaded, it distributes weight across the system rather than creating a single point of stress. The angular aesthetic that defines the truck’s look can be preserved by rails and crossbars that tuck into the lines of the bed and roof, rather than sitting on top with a bulky silhouette. In other words, the rack should feel like a natural extension of the vehicle’s design rather than a clumsy afterthought. This matters not only for aesthetics but for the long‑term durability of the mounting hardware and its integration with high‑duty track rails.

Choosing a compatible ladder rack is not merely about the fit. It is about the broader philosophy of modularity and upgradeability. Some systems offer expanded flexibility by providing additional adapters that allow you to put the ladder across the bed rails or across the roof rails, or to switch from a ladder cradle to a long‑load carrier bracket. When evaluating options, it is essential to consider how the system handles multiple configurations across different trips. Can you quickly move from a single ladder to a dual‑ladder setup, or to a different gear ensemble entirely, without sacrificing security or needing specialized tools? The best solutions deliver that flexibility with consistent clamp engagement and reliable locking mechanisms, so the user can reconfigure with confidence and speed.

For readers seeking a deeper dive into related mounting solutions and how they relate to the broader cargo‑carrying ecosystem, a practical reference exists in the Roof Racks guide. This resource explores the support framework, common mounting patterns, and the flexibility offered by a rail‑based system that prioritizes secure engagement and ease of use. You can explore that overview here: Roof Racks.

Beyond the basics of fit and finish is the reality of third‑party offerings in the ladder rack space. It is common for multiple manufacturers to design their products to integrate with the L‑Track rails, but not all options are created equal. The critical step is ensuring that any ladder rack you consider includes clamps or mounting hardware that are explicitly approved for use with the truck’s track system. Some third‑party designs may claim compatibility but rely on generic fasteners that do not ride correctly in the tracks, risking loosening under load or during sharp maneuvers. A responsible selection process asks for documentation that demonstrates track engagement, load distribution tests, and a mounting method that won’t degrade the rails over time. This due diligence helps maintain the integrity of the track system and the safety of the cargo being carried.

In this ecosystem of compatibility, the practical path forward is simple: start with an assessment of the rack’s intended load, verify the hardware is track‑specific, and confirm the assembly can be configured for both bed and roof use without requiring any invasive modifications. If possible, choose hardware that allows for straightforward reconfiguration, so a single system remains valuable across different cargo scenarios. Remember that the goal is not a parade of gadgets but a coherent, adaptable platform that unlocks the vehicle’s potential while preserving its core integrity. The L‑Track system is the connective tissue that makes this possible, binding the rack, the gear, and the vehicle into a single, predictable solution rather than a collection of incompatible parts. Within that framework, the ladder rack becomes more than a means of transport; it becomes a durable partner in work and play, ready to deploy when needed and to stow neatly away when not.

If you’re curious about how this philosophy translates into real‑world setups, consider the practical workflow of preparing a truck for a multi‑stop day. Imagine loading a long ladder across the bed’s rails and using the track’s clamps to secure it at two or three contact points along its length. The load sits firmly, with minimal movement even as the truck slows, accelerates, or traverses uneven pavement. When the ladder is no longer needed, those same clamps slide away along the track, and the rack system retracts into a sleek, low‑profile configuration that preserves bed space for smaller items. This is the essence of a well‑integrated, L‑Track‑based ladder rack: a universal, repeatable solution that respects the vehicle’s built‑in architecture, supports diverse cargo, and remains reliable month after month, season after season.

External resource for further exploration includes detailed sheets and mounting options that illuminate the specifics of clamp design and bracket compatibility. Access the external reference here: https://www.xprite.com/products/cybertruck-roof-bed-rack

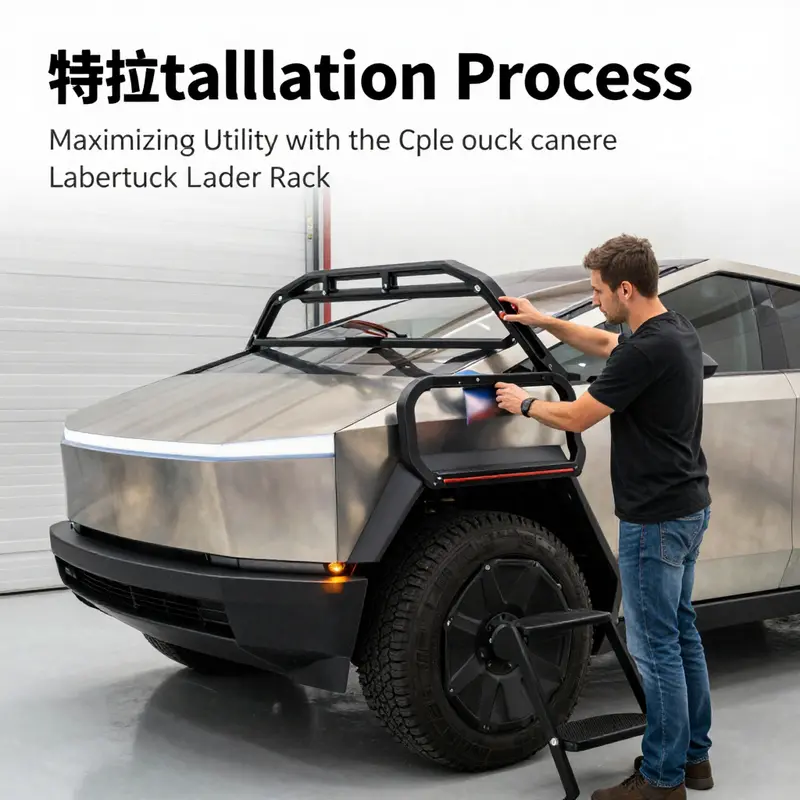

Bolt-On Brilliance: Seamless, Torque-Smart Installation of the Cargo Ladder Rack on an Angular Electric Pickup

A ladder rack that clamps to a truck’s roof rails represents more than a simple add-on. It’s a deliberate extension of the vehicle’s utility, a piece designed to keep long items secure without altering the truck’s lines or its warranty. The objective when installing such a system is not merely to attach a piece of metal; it is to create a stable, well-distributed platform that respects the vehicle’s weight limits and its geometry. In the real-world rhythm of work and adventure, the rack must integrate with the truck’s factory mounting points, rely on a bolt-on approach, and deliver a predictable, repeatable performance. This is the kind of accessory that turns a bare cargo bed into a modular backdrop for ladders, bikes, or long, awkward loads, all while preserving the vehicle’s signature silhouette and resale value. The emphasis from the outset is on a clean, bolt-on experience that requires no drilling or permanent modifications, a detail that matters to many owners who want to protect their factory warranty while expanding their payload capabilities.

Preparation begins long before the first bolt is touched. Gather the hardware provided with the rack, a socket wrench with a comfortable range, a torque wrench, and a helper who can assist with precise alignment. The goal is not brute force but measured accuracy. The rack frame is designed to sit across the vehicle’s roof rails, leveraging the existing points of attachment to create a balanced base. This is where the engineering mindset shines: alignment must be exact to ensure even load distribution across the rail interface. A misaligned rack can introduce subtle stresses that, over time, translate into looseness, creak, or, in the worst case, stress concentrations in the roof structure. The preparation phase, therefore, becomes a practical ritual—checking the rails for debris, confirming that the rail ends are unobstructed, and verifying that the rack’s mounting holes align with the vehicle’s mounting points. The steps are simple, but their impact is real: a precise start reduces the chance of cross-threading, uneven torque application, or later re-tightening that disrupts driver comfort or passenger safety.

The alignment stage is where the rack begins to reveal its design intent. With a helper holding the frame in place, gradually bring the four corners into position so the rack sits level and square to the vehicle. The goal is an even gap around the frame where it meets the rails and a consistent contact area along the length of each rail. This careful positioning is not cosmetic; it’s structural. The load path travels from the rack through the mounting hardware into the rail, then into the vehicle’s structural elements. Any deviation can create a point of leverage that complicates tightening or, worse, introduces flex during dynamic driving conditions. The alignment phase also invites a practical consideration: weight distribution. A ladder or long item, when secured, should rest across the rack so its weight sits squarely between the rail mounting points. Visual checks are complemented by light hand pressure on the rack’s corners to ensure there is no twist or wobble once the bolts are fastened. The process blends the tactile feel of hardware with the spatial awareness of a builder who understands how every component shares the same purpose: stability under load, minimal vibration, and long-term reliability.

Securing the rack with the provided bolts is the core of the installation. The manual is your compass here. It specifies torque values that should guide every fastener, ensuring that each attachment achieves the intended clamping force without overloading the material. Torque control is not a luxury; it is part of the chain that links the rack to the vehicle’s structural capacity. The bolts themselves are chosen to create a robust interface with the factory mounting points while leaving the roof rails untouched and the surface free of permanent modification. A healthy habit is to start each bolt by hand to find the thread and confirm smooth engagement before switching to the torque wrench. Working in a diagonal sequence—tightening opposite corners in a crisscross fashion—helps to seat the frame evenly and reduces the risk of warping the mounting points as you progress. A helper’s role becomes especially valuable here, offering a second set of eyes to verify that no corner lifts or shifts as the clamps draw tight.

One of the most important promises of this bolt-on approach is the absence of any drilling or permanent modifications. That constraint honors the vehicle’s factory warranties and keeps the vehicle’s original structure intact. It also makes retrofitting or relocating the system easier should ownership change hands or if the vehicle is pressed into different service in the future. The no-modification philosophy does not, however, cheapen the setup. It demands careful measurement, disciplined torque application, and a respect for the way a rugged, aluminum framework interacts with a modern truck’s structural rails. The rack’s aluminum construction, finished with a durable powder coat, is designed to resist the kind of road grit, spray, and weather cycles that urban and off-road drivers alike encounter. The finish isn’t just cosmetic; it reduces surface wear that could otherwise transfer to the rail and hardware over time, helping to maintain a clean, maintenance-friendly interface.

Final checks are the moment of truth. After all bolts are torqued to spec, the rack needs to be tested against dynamic loads and checked for any signs of movement at highway speeds or on rough surfaces. A quick method is to test the rack’s stiffness by applying a firm, controlled push to each corner and listening for any creaks or the sensation of looseness. The rack should remain inert under light hand pressure, and there should be no visible gaps between the rack and the rails. The helper can aid by gently bouncing the vehicle at low speed and again at higher speed to expose any subtle flex. If a torque wrench indicates that a bolt has loosened, re-torque promptly and confirm that the sequence remains true. A final step—without loading the rack with items yet—might include a brief post-test walkaround: check the rail ends, inspect for interference with weather stripping, and confirm that the gasket seals remain intact so water intrusion is not a concern. All these checks collectively ensure the installation’s integrity and give a sense of security that the rack will perform under real-world conditions.

Beyond the mechanical how-to, there is a broader design philosophy at work. The rack system is crafted from aluminum with a powder-coated finish, balancing strength with lightness and corrosion resistance. This choice of materials matters when the rack is expected to endure a mix of sun, rain, road salt, and off-road exposure. The combination of a robust load rating—capable of handling up to 200 pounds (about 90 kilograms)—and the versatility of integrated T-slots opens a spectrum of attachment options. The T-slots are more than a convenience; they are a deliberate invitation to customize the rack for the job at hand. A toolbox, a small roof-mounted cargo carrier, or an off-road appendage can be slid into the slot and secured with standard hardware, transforming the rack from a simple ladder support into a modular system for work or play. This modularity aligns with the broader idea of a utility-focused vehicle platform—a vehicle design that anticipates the diverse demands of trades, contractors, campers, and weekend enthusiasts.

In practice, the rack’s utility is evident across a range of use cases. For someone transporting ladders to a job site, the rack provides a dedicated, high-visibility pathway for a long item that would otherwise dominate interior space or risk damage if lashed haphazardly inside a vehicle with a limited loading footprint. The same architecture supports keeping bikes or oversized gear aligned with the vehicle’s center of gravity, reducing the likelihood of sway or contact with passengers or roof contours. Because the rack sits atop factory points and does not require drilling, owners gain confidence in adding or removing loads without markups to the bodywork or the roof itself. This is not simply about capacity; it is about predictable behavior. When you drive with a ladder secured on a rack designed for the purpose, you experience steadier handling and fewer vibrations transmitted through the cargo bed, particularly on longer highway stretches or gravel paths where loose items can begin to shift and create noise.

The practical integration with a broader ecosystem of gear is where the rack shines. The T-slots invite a handful of compatible add-ons, such as toolbox enclosures that can be fastened to the rail, lightweight awnings for shade during on-site days, or extra storage pods that complement the ladder without crowding the interior space. The design language—angular, robust, and utilitarian—echoes the vehicle’s own aesthetic while giving engineers a reliable channel to route accessories along the roofline. In this sense, the rack becomes a bridge between function and form: it respects the vehicle’s distinctive geometry while reinforcing its practical capabilities. For readers exploring a wider spectrum of truck accessories, the Trucksdiy hub offers a curated guide to related components and modular options that pair well with this kind of bolt-on system. Trucksdiy accessories hub

Maintenance concerns, though often understated, deserve attention. Aluminum surfaces with powder coating require occasional cleaning to remove road grime that can trap moisture and precipitate corrosion in hidden channels. A soft brush and mild detergent are usually enough to preserve the finish, followed by a thorough rinse and a gentle dry. Because the rack relies on a bolt-on interface, periodic re-tightening may be necessary after the first few hundred miles of driving, especially after long highway treks or off-road runs that expose the system to temperature swings and vibrations. The goal is not to chase every potential issue but to maintain a stable baseline of torque and alignment. With proper care, the system remains a faithful ally for passing tall ladder-rack demands or hauling long, bulky items that would otherwise require compromises elsewhere in the vehicle’s payload strategy.

The installation experience, at its core, embodies a simple truth: you gain more utility without surrendering the vehicle’s original character. By anchoring the rack to the existing roof rails and using a bolt-on approach, the process respects both the engineering and the identity of the truck. It invites owners to think of the cargo bed as a dynamic workspace—one that can adapt to a ladder, a bike, a long piece of lumber, or a roof-mounted toolbox—without turning the truck into a different vehicle. This is the essence of a well-executed accessory system: it should enhance capability, preserve warranty, and preserve the vehicle’s essential design language. As you move from installation to daily use, the rack’s capabilities become clearer. It is not just a platform; it is a configurator for how you tilt the balance of space, weight, and access to gear. The result is a more capable vehicle that remains true to its original intent: a practical platform that meets the demands of work, travel, and everyday exploration.

External reference for deeper technical alignment and fitment specifics can be found in the official fitment guides. This material provides precise measurements, torque targets, and the exact sequencing recommended by the guide authors. While this chapter has focused on the practicalities of a bolt-on installation, consulting the fitment guides ensures you are aligned with the latest recommendations for your exact vehicle configuration and any updated hardware that might be introduced in newer production batches. External resource: https://www.tesla.com/support/fitment-guides

Final thoughts

The Tesla Cybertruck Ladder Rack represents an invaluable addition for business owners looking to enhance their operational efficiency. Through its thoughtful design, impressive load capacity, and seamless integration with a variety of accessories, the ladder rack is not just an enhancement—it’s a necessity. The straightforward installation process ensures that you can easily equip your Cybertruck for everyday tasks or adventures. By implementing this sturdy accessory, businesses can maximize their transport capabilities and streamline their operations, leading to improved productivity and satisfaction.