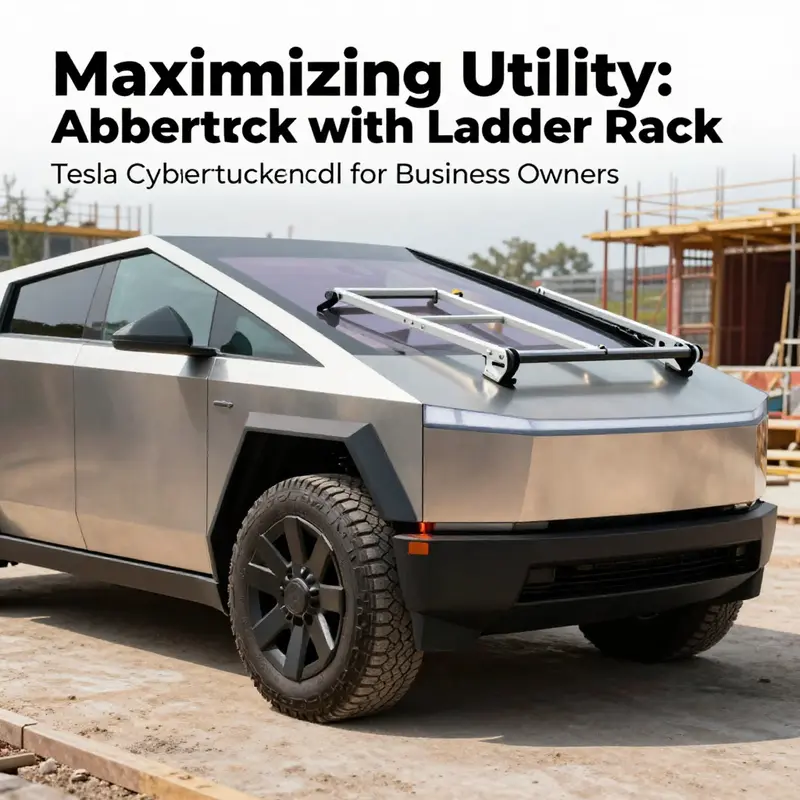

The Tesla Cybertruck, with its cutting-edge design and robust durability, stands out as a promising vehicle for business owners seeking utility and performance. The addition of a ladder rack enhances its functionality, allowing the transport of lengthy or bulky items, perfect for various trades like construction, maintenance, and delivery services. This article delves into the valuable aftermarket solutions available, critical installation considerations, payload capacities, and the aerodynamic implications of using a ladder rack with the Cybertruck. By understanding these facets, business owners can make informed decisions that leverage the Cybertruck’s capabilities to enhance their operational efficiency.

Rising Utility: Expanding the Cybertruck’s Reach with Aftermarket Ladder Racks

On a sun-worn jobsite where the day’s dust glitters like metal, a rugged pickup sits with a ladder secured along its profile. The scene captures a simple truth about modern utility vehicles: sometimes the tool you need isn’t only in the powertrain or the payload bed, but in how you extend that payload to the world. For owners who want to stretch the practical length of their workdays, aftermarket ladder racks offer a compelling route. The concept is straightforward enough: add a secure framework that spans the bed, giving long items a safe, stable home above the cargo area. Yet for a vehicle with a distinctive silhouette and a bed that measures roughly six and a half feet, the choice of rack is less about swapping a part and more about integrating a system that respects geometry, weight, and the rhythm of the vehicle’s performance. In this chapter, we’ll consider how these racks come to life in the real world, what matters most when selecting and installing one, and why, for some tasks, a truly integrated bed rack system can deliver a cleaner, more capable solution than a loose top-mounted carrier.

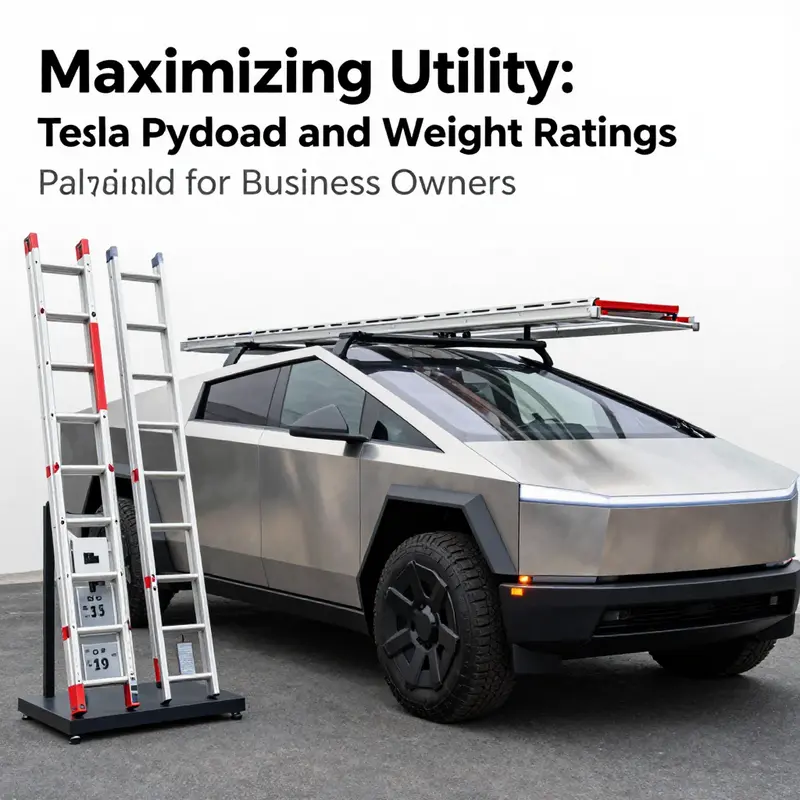

The absence of an official factory option for a ladder rack in this class of truck is not a signal that the vehicle cannot shoulder the job; rather, it nudges buyers toward a family of aftermarket solutions that are tailored to the vehicle’s distinctive frame and bed geometry. These are not off-the-shelf add-ons that pretend to fit every truck; they are purpose-built, engineered specifically for the frame and bed length, with mounting points and load paths designed to keep the rack from becoming a weeks-long project or a surprise to the vehicle’s center of gravity. Materials typically run toward aluminum or steel, chosen for balance between strength, weight, corrosion resistance, and the way they interact with a vehicle that prizes both form and function. The practical implications are immediate: a rack must be rated for the weight of the ladder or long pole it carries, and it must do so without compromising bed access, tailgate operation, or the vehicle’s handling characteristics on uneven terrain or gravel roads. When you’re hauling tall or bulky items, you want a system that behaves like a permanent part of the truck, not a temporary add-on that rattles loose at the first washboard.

Fitment begins long before a single bracket is bolted into place. The bed size, roughly six and a half feet, dictates how the rack sits relative to the cab and tailgate, how much space the ladder needs above the bed, and how the rack interacts with the sides and floor of the cargo area. The mounting philosophy typically centers on using the vehicle’s existing mounting points, or on brackets that anchor into the bed walls and floor with hardware designed to distribute load along strong channels rather than concentrating it at a single point. For some installations, minor drilling is required, or a use of factory-like mounting points that are present on the vehicle’s chassis. The installer’s goal is to preserve the integrity of the bed’s structure while creating a platform that can transfer the weight of a ladder into firm, predictable contact points. That means doing more than simply suspending a bar across the top; it means engineering a rack that ties into the vehicle’s geometry in a way that respects the axial forces that occur when you accelerate, brake, or crest a ridge at speed.

Materials are a balancing act. Aluminum racks deliver a lighter touch, often resisting corrosion with a natural sheen that coordinates with the vehicle’s metalwork without drawing attention to itself. Steel racks, while heavier, tend to offer a more robust look and feel and can be built with thicker tubing for additional rigidity. In either case, a well-designed rack uses brackets and cross-members shaped to resist flex under load, reducing the risk of ladder sway, rattle, or misalignment when traversing rough terrain. The choice between materials becomes a question of mission profile: if the vehicle regularly sees high-speed runs on highways with occasional off-road stretches, a stiffer, heavier rack may hold its alignment better over time; if the work involves shorter trips with careful handling, a lighter aluminum option can minimize the impact on overall weight and fuel economy. Regardless of material, the rack’s finish matters too. The best options employ corrosion-resistant coatings that hold up against road salt, water spray from wet backroads, and the occasional scrape from a low-hanging branch in a remote work area. A well-finished rack keeps its lines clean, which helps maintain the vehicle’s aesthetic and reduces the chance of hardware wearing prematurely.

Weight rating and load distribution are more than numbers on a spec sheet. They translate into real-world decisions about what you carry and how you carry it. A ladder rack must be able to bear the weight of a ladder, plus any ancillary items strapped alongside it, without transferring that load to the vehicle’s tailgate hinge or bed-mounted ancillary equipment. The load’s center of gravity is also a critical consideration. A tall, heavy ladder perched high on the rack can raise the vehicle’s center of gravity, affecting braking stability, cornering feel, and the way the suspension compresses when traversing a dune or a washboard. Designers and installers thus emphasize secure mounting points, rattle-free fittings, and hardware that remains tight through vibration and temperature swings. In this sense, the choice between a modular system that can hold multiple attachments—ladders, poles, or other bulky gear—and a more focused single-use rack becomes a question of how many tasks you expect the rack to manage at once. A modular rack provides adaptability but demands careful organization; a purpose-built ladder rack tends toward simplicity, reliability, and a cleaner silhouette.

From a user’s perspective, the installation experience can swing the decision toward one of two broad directions: a dedicated bed rack system that integrates with the bed’s original mounting framework, or a more traditional overlay rack that attaches to sidewalls or the floor via brackets and clamps. An integrated system tends to offer a more cohesive aesthetic and a more predictable interaction with the bed’s geometry. It can feature an integrated MOLLE-style attachment grid, which is a modular platform that enables flexible organization of accessories and gear. This approach creates not only a robust ladder-holding structure but also a versatile base for strapping down tools, recovery gear, or other long items that benefit from multiple tie-down points along the rack. The clean, factory-like appearance is part of the appeal, especially for owners who want utility without visually signaling a retrofit. In contrast, a traditional over-the-bed setup can be excellent for those who want to upgrade or swap configurations without committing to a single integrated system. It may be easier to remove seasonally or adapt to other vehicles but can look more conspicuous and risk misalignment if not carefully installed.

Access and aerodynamics are the quiet, ongoing concerns that often determine long-term satisfaction with any rack. A ladder or pole sitting high on a rack can catch wind at highway speeds, producing slightly more drag and a faint howl that annoys some drivers and amuses others. The practical consequence is prudence in selection and placement: keep the rack height proportional to the vehicle’s roofline and cab clearance, and verify that the ladder’s footprint does not obstruct the rear window, exhaust path, or any sensors that might be present on newer electronics-equipped trims. It’s also wise to consider how a rack affects the truck’s approach to off-road obstacles. On rough surfaces, increased wind resistance is the least concern; more important is the rack’s tendency to stay rigid and stable under torque, ensuring that ladders don’t shift or vibrate into the sidewalls during a climb or descent. Maintenance is straightforward but essential. Regular checks on mounting hardware, brackets, and cross-members help prevent loosening, while periodic lubrication of any sliding or rotating components reduces wear. A rack that remains quiet and steady over time tends to deliver greater peace of mind, especially when the job requires frequent stops and starts in remote locations.

Within this ecosystem of choices, a fully integrated bed rack system presents a compelling narrative for many owners. It promises a secure, robust platform with built-in attachment points for organization and quick access. The integrated approach can deliver a streamlined, cohesive look that feels like a natural extension of the vehicle rather than an aftermarket add-on. If the goal is to maximize utility while preserving a clean, purposeful profile, an integrated system—designed with precise fitment and a suite of compatible accessories—often becomes the preferred path. It’s not merely about carrying a ladder; it’s about embracing a modular, scalable framework that supports the full spectrum of overlanding gear and long items, from bicycles to tents, poles to skids. For those who occasionaly require additional cargo capacity, the system’s architecture can accommodate future upgrades without sacrificing the vehicle’s core geometry.

For readers who are exploring aftermarket ladder racks as a practical upgrade, there is a growing body of guidance that emphasizes careful measurement, realistic load calculations, and a preference for products engineered to integrate with the bed’s structural cues. The emphasis is on choosing a system whose mounting points align with existing structures and whose hardware distributes load evenly. The goal is a solution that remains dependable after miles of variable terrain and across changing weather. As you assess options, consider not only the rack’s ability to hold height but also its capacity to organize, protect, and secure tools. A thoughtfully designed ladder rack should help you stay organized, reduce the time spent loading and unloading, and minimize the risk of gear damage during transit.

To facilitate a deeper dive into the subject, readers can explore a dedicated guide that outlines how to evaluate and install a ladder rack for this particular platform. The guide walks through fitment considerations, mounting points, and the balance between weight, accessibility, and aerodynamics. It emphasizes the importance of choosing a system that aligns with your typical use case, whether you are tackling construction tasks, field service work, or off-grid adventures that demand reliable gear carriage. It also outlines practical steps for installation, including how to identify mounting locations, prepare the bed for brackets, and verify the rack’s alignment before loading heavy items. This resource, while focused on a specific rack family, provides principles that are broadly applicable to any aftermarket solution designed for a bed of this size and shape.

In addition to the core ladder-rack system, there are complementary accessories that can augment the overall utility without overpowering the design. A well-matched accessory can dramatically improve the vehicle’s versatility for long trips or backcountry work. For instance, a front-trunk cooler unit can be a practical complement, giving you a secure, weather-resistant storage option that keeps perishables and beverages cold during long drives or hikes. The aesthetic alignment with the vehicle’s angular, industrial character helps maintain a cohesive look while delivering real-world convenience. The combination of a sturdy ladder rack and a purpose-built cooler is a classic pairing for road trips and remote deployments, turning a simple ladder into part of a broader, well-organized toolkit.

The practical message here is not simply about mounting gear; it’s about designing a workflow. A ladder rack that integrates cleanly with the bed, and a modular storage approach that uses attachment grids and systematic tie-downs, can transform how you use the vehicle for work and adventure. It shifts garage-to-field routine into a single, well-orchestrated system. When you approach this choice with an eye toward geometry, load path, and future expansion, you arrive at a solution that feels like a natural extension of the truck—one that respects the vehicle’s distinctive design while expanding its practical capabilities.

For readers seeking actionable direction, a helpful step is to review a concise, vehicle-specific ladder-rack guide that discusses fitment, mounting, and load considerations. This internal resource provides a practical checklist you can apply as you compare options, ensuring that the final choice aligns with your operational needs and your vehicle’s structural realities. The link below points to a detailed discussion that can serve as a useful starting point for anyone prioritizing reliability, organization, and integration over time. cybertruck-ladder-rack. By grounding decisions in measured fit, robust construction, and thoughtful assembly, you can upgrade your truck’s utility without compromising safety, handling, or the clean lines that make the vehicle recognizable on the trail or the job site.

External resource: https://www.tesla.com/cybertruck/accessories/complete-bed-rack

null

null

null

null

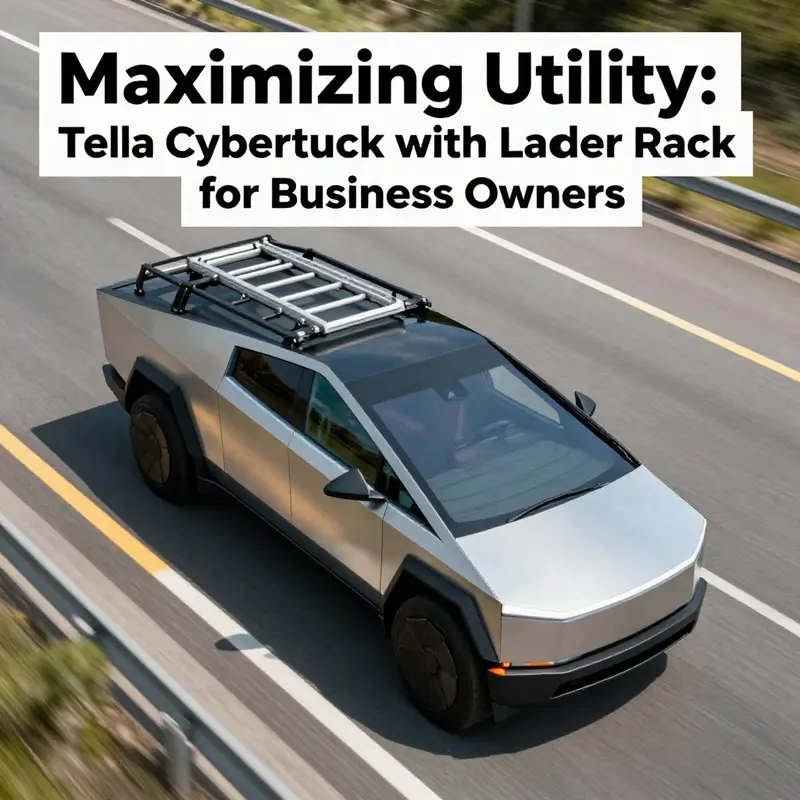

Raising the Rack, Reducing the Range: Aerodynamic Realities of a Cybertruck with a Ladder Rack

The cybertruck has a distinctive shape designed for predictable airflow at highway speeds. Its flat panels and sharp angles guide air along the sides toward the bed with the goal of minimizing drag and wake. The overall geometry helps keep the flow attached to the surface and reduces the power penalty that comes with more complex shapes. A careful balance exists between utility and efficiency in this design.

With a ladder rack added, the flow is disrupted by a new solid element that sits above the bed. The rack increases frontal area and can act as a flow deflector, causing earlier separation and a larger wake. The drag penalty grows with rack height and cross section, and the magnitude rises as speed increases. Even modest racks can produce noticeable energy costs at highway velocity, especially on long trips where the wind is persistent.

Beyond drag, the rack tends to generate a more energetic shear layer behind the vehicle which can contribute to cabin buffeting in certain wind conditions. The interaction with the Cybertruck cabin resonance is sometimes perceptible as a slight increase in wind noise when the rack is heavily loaded or when crosswinds are strong.

Mounting geometry matters. A low profile mounting that hugs the bed or roof can reduce disruption relative to a tall freestanding configuration. The closer the rack follows the vehicle silhouette, the less it stands off the body and the smaller the wake. Designers can mitigate drag with streamlined cross sections, rounded ends, and attachments that minimize sharp edges. However even well designed racks introduce some drag compared with the stock configuration.

The weight and placement of the rack also shift the center of gravity. A heavier rack that sits high increases the vertical load and can influence handling during cornering and on rough terrain. Secure mounting, balanced loading, and proper tie downs help keep dynamic loads from coupling with wind gusts and producing sway.

In practical terms the decision comes down to three linked ideas design alignment, mounting integrity, and adaptive usage. Design alignment means choosing a rack that closely matches the truck profile and uses crossbars and end caps that reduce flow separation. Mounting integrity means robust attachment with a low profile to minimize wind induced loads and keep the rack steady. Adaptive usage means loading ladders thoughtfully to preserve stability, securing items to prevent movement, and retracting or removing the rack when it is not needed.

From a planning perspective it helps to consider typical mission profiles and even to review simple wind tunnel or CFD results when available. The physics is clear a larger surface area and a more pronounced silhouette increase drag and wake and the practical effect is a trade off between utility and efficiency.

In closing a ladder rack on a Cybertruck is a classic case of utility versus efficiency. With careful selection mounting and loading discipline it can deliver important practical value while keeping aerodynamic penalties reasonable for the intended use. The rack becomes a deliberate design choice rather than an afterthought and a path to harmonize capability with the vehicle’s aerodynamic intent.

Final thoughts

Integrating a ladder rack into your Tesla Cybertruck can significantly enhance its utility for various business applications. With the right aftermarket solutions, careful installation, and an understanding of payload capacities and aerodynamic impacts, business owners can optimize their transport capabilities. Investing in a ladder rack ensures that your Cybertruck meets the demands of professional tasks while maintaining safety and functionality. Embracing this upgrade could streamline operations, making your business more efficient and adaptable in a competitive landscape.