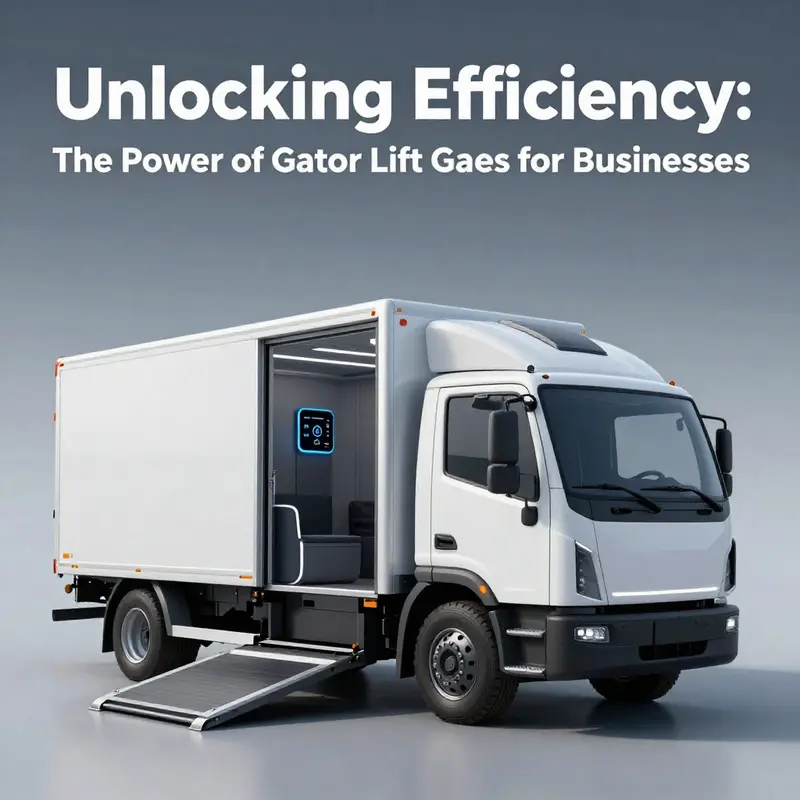

The gator lift gate is not just a convenience; it’s a game-changer for various industries ranging from logistics to construction. These specialized liftgate systems are essential for facilitating the smooth loading and unloading of heavy cargo, thus optimizing operational efficiency and minimizing workplace injuries. As businesses strive for effectiveness in their transport operations, understanding the functions, innovations, and economic impacts of gator lift gates becomes crucial. This article will guide you through the essential aspects of gator lift gates, including their technical advancements, economic benefits, compliance with safety standards, and future trends.

Unraveling the Gator Lift Gate: A Deep Dive into Liftgate Mechanics, Safety, and Industrial Reach

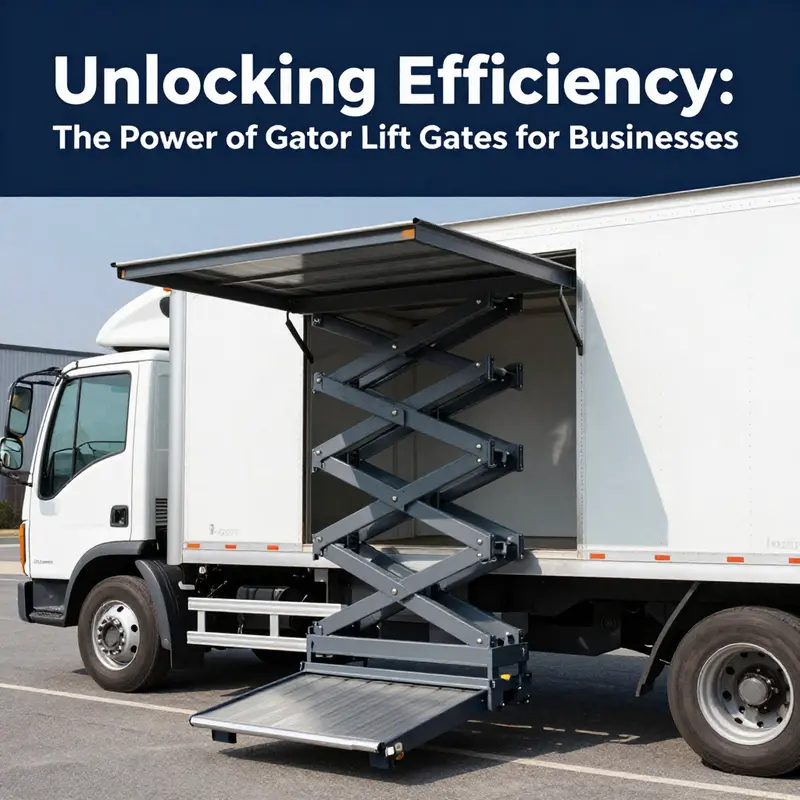

The term “gator lift gate” often emerges in conversations as a shorthand for a liftgate—yet in technical circles it is more accurately described as a rear-access lifting system designed to move heavy cargo from ground level to a raised cargo platform. The misnomer can blur the practical realities of what these mechanisms do and how fleets rely on them. What remains clear is that a liftgate—whether on a delivery van, a work truck, or a trailer—embeds a careful blend of physics, engineering, and safety into a compact, durable package. At its core, the liftgate is a platform that can descend to ground level and rise to the back of a vehicle, enabling cargo to be loaded or unloaded without forklifts or manual lifting for every item. For a deeper look into the practical aspects of liftgates, refer to the dedicated overview on liftgates that discusses how these systems integrate with cargo handling: liftgates. The liftgate’s value becomes especially evident when the items are heavy, awkward, or stored in locations without loading docks. In these situations, the liftgate becomes not just a convenience but a safety feature, reducing the risk of back injuries and the wear on workers who would otherwise lift, carry, or wheel items up stairs or onto a ramp. The technology behind the liftgate is pragmatic and purposeful, built to perform in environments that expose equipment to dust, moisture, and repeated use. The design emphasizes ruggedness and reliability, with attention paid to materials, mechanical movement, and control systems that must respond accurately every time the operator presses a button, slides a switch, or triggers a sensor. In many fleets, the liftgate operates as a critical node in a broader logistics network. Its performance ripples through delivery times, on-site safety protocols, and even fuel efficiency, since the driver can quickly move from loading to delivery without waiting for external equipment to arrive. The liftgate’s place in this ecosystem is not merely about moving weight; it is about enabling a smooth, predictable workflow that reduces downtime and accelerates throughput. In practice, liftgates are coupled with hydraulic or electric actuation, and the choice between those powertrains influences everything from maintenance schedules to energy consumption. Hydraulic systems excel in lifting heavy loads with robust hold-in-place strength, while electric or electric-hydraulic hybrids can offer quieter operation and simplified control through electronic interfaces. The decision often hinges on the expected load profile, the operating environment, and maintenance resources. An important design consideration is the platform’s height range. A versatile liftgate provides adjustable opening heights so operators can tailor the working height to the load and to the vehicle’s loading dock alignment. This memory-like feature reduces repetitive bending and reaching, making daily tasks less strenuous and more predictable. It also minimizes the risk of misalignment that could cause damage to cargo or to the vehicle itself. The platform’s dimension, weight rating, and surface texture are calibrated to secure various cargo types—from lumber and machinery to boxes and palletized goods. A non-slip surface, reinforced edges, and edge guards are common elements that help keep loads stable during ascent or descent. Liftgates also incorporate safety interlocks and sensor systems. Obstacle detection, soft-stop controls, and audible or visual alerts are standard in many designs to prevent accidental closure on an object or a person. When an obstruction is detected, the system can stop and reverse, giving the operator a clear signal to reposition items before proceeding. This automated safeguard contributes to a safer work environment and reduces the likelihood of costly damage to goods and equipment. The control logic behind liftgates balances ease of use with reliability. A typical setup includes a manual override for power loss, ensuring that cargo can still be loaded or unloaded in emergencies. Operators appreciate controls that are intuitive and accessible, whether through a handheld remote, a dashboard switch, or a foot pedal in certain configurations. The emphasis on human-centered design is not accidental; it reflects a broader industry trend toward intuitive interfaces that minimize training time and enhance operator confidence. In the context of commercial logistics, liftgates serve a practical function that complements other equipment in the fleet. A hydraulic or electric platform that lowers to ground level enables ships of various sizes to deliver to sites lacking loading docks. For Last-Tier deliveries, this capability can dramatically expand service coverage, as drivers can reach customers who would otherwise require additional handling steps or alternate equipment. The operational impact is measurable: drivers spend less time per drop, and teams can schedule more stops within a shift. This efficiency, in turn, supports competitive service levels and improves overall route planning. The materials chosen for liftgates reflect the demanding environments in which they operate. Heavy-gauge steel or aluminum alloys provide the rigidity and fatigue resistance necessary for repeated cycles and exposure to temperature swings, rain, or road salt. The platform, hinges, and main frame are engineered to resist wear and to survive the vibrations and jolts common in rural roads or urban delivery corridors. Yet this robustness must be balanced with weight considerations. Heavier liftgates impose greater vehicle tare, fuel consumption, and braking demands. Manufacturers and fleets therefore seek an optimal equilibrium between payload capacity, operating weight, and ease of use. Beyond the hardware, liftgates represent a convergence point for fleet technology and safety regulation. Standards and guidelines shape how a liftgate is designed, installed, and maintained. Regular inspections, calibration of sensors, and verification of load ratings help ensure ongoing safety. Training for operators is essential, covering proper loading procedures, weight distribution, and the correct sequence for deploying and stowing the platform. The evolution of liftgates traces a path from straightforward mechanical devices to integrated systems that accommodate modern logistics needs. Technological enhancements—such as height memory settings, more sensitive obstacle detection, and smarter control interfaces—have reduced operator effort and increased reliability. Some designs optimize energy use by prioritizing regenerative features in certain hydraulic cycles or by coordinating with the vehicle’s electrical system. This trend toward smarter, safer, and more efficient equipment aligns with a broader movement in vehicle design toward maximizing payload while minimizing injuries and downtime. It also dovetails with industry shifts toward data-driven fleet management, where liftgate activity can be logged and monitored as part of overall delivery performance. The labeling of the term “gator lift gate” without a standard definition underscores the importance of precise terminology in engineering and operations. While the phrase may circulate informally, the functional reality remains straightforward: a liftgate is a dedicated rear-access mechanism that can raise or lower a platform to bridge the gap between ground level and a vehicle’s cargo area. The emphasis on safety, reliability, and efficiency is consistent across the industry, regardless of the specific name applied to the device. As fleets continue to pursue ever-greater efficiency in loading and unloading, liftgates will likely evolve to integrate more advanced sensing, connectivity, and energy management features. Their role in reducing manual handling, protecting workers, and enabling flexible delivery strategies makes them a quiet workhorse of modern logistics. For readers who want a concise primer on liftgate concepts and how they fit into everyday vehicle design, the liftgates page provides accessible background and practical guidance on selection, installation, and use. That resource, linked above, offers a grounded starting point for understanding the mechanical essentials and the safety frameworks that keep these systems reliable on the road. As an ongoing conversation between equipment design and fleet practice, liftgates illustrate how a single component can ripple through operations, shaping how goods move from dock to destination. In future explorations, we can examine how sensor fusion, lightweight materials, and smarter hydraulic circuits might further enhance these platforms while preserving the core advantages that make them indispensable to loading and unloading at scale. External reading can broaden this view: The Free Dictionary entry on liftgate offers a concise, widely accessible definition that complements the technical detail discussed here.

Gator-Strength at the Rear: How Rugged Lift Gates Redefine Load Handling

Rear lift systems designed for heavy cargo act as quiet workhorses in modern fleets. In the world of transport and logistics, a gator-style lift gate stands out for ruggedness and reliability. These devices are not merely mechanical platforms; they are integrated pieces of a vehicle’s operational backbone. A gator-style lift gate combines a rear entry with a platform that can raise, lower, tilt, and, in some configurations, extend away from the vehicle to create a stable bridge to the ground. The term evokes strength and resilience, traits operators demand when every pallet, drum, or machine weighs into the workflow. The essential promise is straightforward: reduce manual lifting, speed up loading cycles, and keep workers safer as they move heavy loads from dock to deck. Yet behind that promise lies a complex balance of materials, actuation methods, control logic, and safety safeguards. The best designs do not rely on brute force alone; they optimize weight, rigidity, and control so that lift is predictable, repeatable, and resilient under daily use. This chapter looks at what makes a gator-style lift gate perform and how it fits into the broader ecosystem of transport and material handling.

Material choice matters as much as the mechanism that moves the gate. Heavy-duty lift gates typically use thick steel or aluminum alloys. Steel offers strength and fatigue resistance, while aluminum cuts weight and helps with corrosion in damp or winter environments. Many gates employ protective coatings—powder finishes, galvanization, or specialized paints—to withstand road salt and industrial grime. The platform itself must bear heavy axial loads but also resist bending and warping over time. The hinge lines require precision machining and robust pins or bushings to maintain alignment through thousands of cycles. To manage the vertical range, gates offer adjustable travel—an essential feature when the vehicle operates at docks with variable dock heights or when the gate must clear protrusions like curb edges or ramps. In practice, this translates to a gate that can be set to a higher or lower working height, improving ergonomics and reducing fatigue for the operator. The integration with the vehicle frame is not an afterthought; it defines how the gate affects the vehicle’s center of gravity, axle loading, and overall road handling. A well-designed gate uses reinforced mounting points, anti-sway brackets, and careful routing of hydraulic lines or electrical cables to minimize wear and accidental damage.

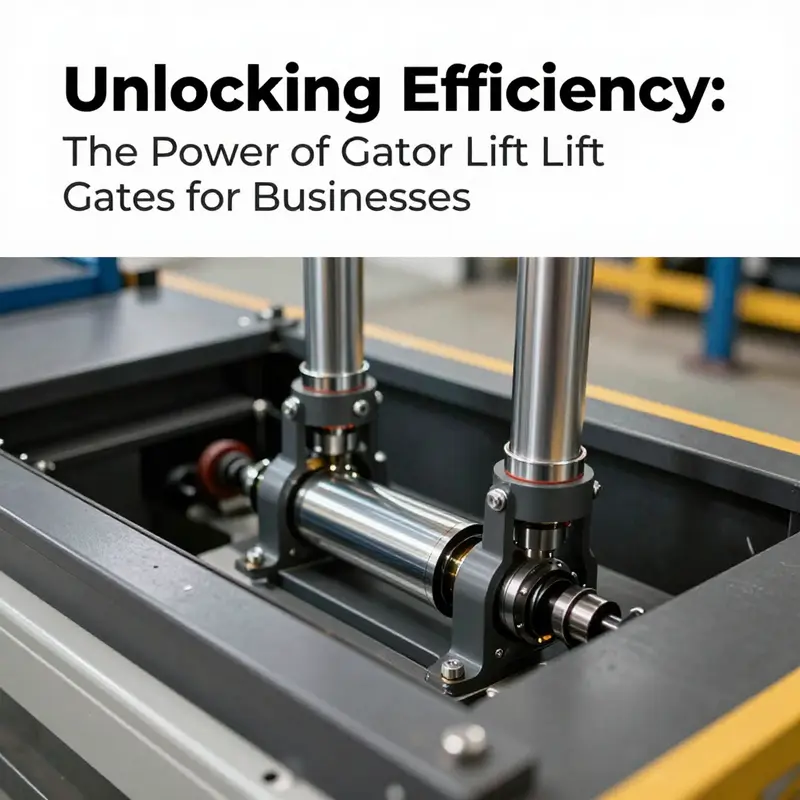

The heart of the lift is the actuation system. Hydraulic cylinders are common for their smooth, controllable motion and high load capacity. Electric-powered actuators are increasingly popular for simplicity, energy efficiency, and the possibility of precise electronic control. Some configurations blend both: hydraulics provide the initial lift, while an electric pump or motor fine-tunes the movement and holds the platform in position. The control logic can be straightforward—one-touch up and down with a safety interlock—or more advanced, featuring programmable limits, soft-start sequences, and automatic safety features that stop the motion if an obstacle is detected. Regardless of the drive method, the system must respond predictably to operator input and to the vehicle’s own dynamics. Safety interlocks safeguard workers during operation, while limit switches protect the mechanism from over-travel. The rise of remote operation adds flexibility, allowing a supervisor to initiate a lift from the cab or a ground position during dock work. At the same time, modern gates often incorporate anti-pinch guards and redundant safety stops to ensure fingers and toes are kept clear during the sequence. In essence, the actuation is the nerve system; it translates human intention into controlled movement while interacting with gravity, weight distribution, and mechanical clearances.

Function without safety is meaningless in a busy loading yard. A robust gator-style lift gate merges hardware with a suite of safeguards. A sturdy locking mechanism prevents unintended opening when the gate is stowed or during transit. Visual indicators and audible alerts inform the operator of the gate’s status, while mechanical bracing and touchdown supports provide a stable stance on uneven ground. Some designs include micro-switches or capacitive sensors that detect the platform’s position and confirm it has reached a safe height before loading proceeds. Surface textures on the platform, along with slip-resistant coatings, help prevent footing slips even in wet or icy conditions. When the gate is in use, a pair of stabilizer legs or legs that extend out to the sides can absorb the load and reduce sway. The goal is to create a predictable, repeatable cycle that reduces the chance of pinch points and dropped loads. This is where the harmonization of electrical systems, mechanical fit, and operator training becomes essential. Even routine maintenance, such as checking hydraulic fluid, inspecting pins, and ensuring bearings rotate freely, contributes to long-term reliability.

From a practical standpoint, the value of a rugged rear lift gate shows up most clearly in the field. In logistics, the gate translates into faster turn times and fewer injuries from manual lifting. In construction and industrial settings, it unlocks the ability to move heavy equipment and bulk materials without extra crane support or additional labor. In agricultural operations, gate systems can handle crates, feed sacks, or fencing material with less strain on workers who must navigate irregular loading zones. The result is a fleet that can adapt to different docks, terrains, and weather without sacrificing safety or efficiency. The technology also influences how fleets think about payload and fuel efficiency. A gate that adds excessive weight can offset the gains from improved loading practices, so designers strive for a balance: sturdy enough to handle the toughest loads, but light enough to avoid diminishing the vehicle’s total payload and fuel economy. The alignment between gate design and vehicle architecture matters here. The mounting approach, the door geometry, and the potential interaction with roll-up doors or loading dock equipment all feed into a coherent system rather than a collection of parts bolted on after the fact. For readers seeking a broader overview of liftgate configurations, see the liftgates page.

Beyond the gate itself, compatibility with the vehicle’s frame, electrical system, and braking matters. A properly tuned gate does not impose excessive drag on the vehicle’s powertrain or interfere with tail-light wiring. Service intervals for hydraulic fluids, seals, and bearing components ensure consistent performance. Operators learn to test the gate’s response in cold and heat, observe any lag in the control system, and check for abnormal noises that might signal wear. The best practices emphasize a culture of proactive maintenance, not reactive repairs. In addition to routine checks, staff receive training on safe operation, including the correct sequence for raising and lowering the platform, how to stabilize the load, and how to secure pallets effectively. The end result is a system that becomes almost invisible in daily work: it helps move items from dock to deck with routine rhythm, leaving human effort focused on planning and coordination rather than brute lifting.

Looking ahead, the evolution of rear lift systems is likely to be shaped by data and smart integration. Actuation components may benefit from sensing that predicts wear and triggers maintenance reminders before failures occur. Control interfaces could become more intuitive, with haptic feedback or guided sequences to reduce operator error. As regulatory frameworks evolve to emphasize safer vehicle adaptations, engineers will continue to refine attachment methods and safety interlocks to provide redundancy without creating bottlenecks in workflow. In this sense, a gator-style lift gate is less about a single gadget and more about an integrated approach to load handling that aligns with broader trends in fleet optimization, ergonomic design, and environmental responsibility. The result is a solution that remains relevant across fleets and industries, not because it is flashy, but because it quietly lowers risk, raises efficiency, and stands up to the relentless demands of daily use.

Interacting with the broader ecosystem of vehicle equipment, a gator-style lift gate resonates with the same philosophy that governs rugged transport tools: design for the worst case, plan for the next dock, and accept that the best outcomes arise from careful alignment between capability, safety, and usefulness. It sits at the junction where engineering meets everyday labor, translating force into controlled motion, and motion into productivity. The chapter’s thread is not about a single replacement part but about a system of pieces that must work in concert. The metal, the hydraulics, the electronics, the operator training, the maintenance routines—all contribute to a consistent, dependable cycle that saves time and reduces risk. As fleets evolve toward greater automation and modular customization, the role of the rear lift mechanism stays consistent: it is a gateway that transforms a static platform into a workhorse that can adapt to a range of goods, environments, and personnel. The gator-style lift gate, in its thoughtful integration of strength, control, and safety, stands as a practical expression of how modern logistics balance efficiency with human well-being.

null

null

Guarding the Gate: Safety Standards, Compliance, and Confidence for Heavy-Duty Lift Gates

Heavy-duty lift gates serve as vital links between a vehicle’s rear aperture and the load it carries. They are not mere appendages but active safety systems that hinge, fold, lift, and sometimes slide heavy cargo in and out of a trailer, van, or work truck. In the absence of a single, universal “gator lift gate” standard, the safety of these systems rests on a careful blend of general machinery safety principles, vehicle safety standards, and industry best practices. The goal is clear: design, install, and operate a gate that performs reliably while protecting people from injury and cargo from damage. That objective begins with a disciplined risk assessment conducted early in the design phase and carried through every stage of life, from procurement to maintenance. The guiding compass here is ISO 12100, a foundational standard that codifies the need to identify hazards, assess their severity and probability, and apply a hierarchy of controls to eliminate or reduce risk. In practice, that means engineers must consider pinch points, gravity-driven motion, sudden stops, abrupt reversals, and the potential for items to shift or fall during operation. Risk reduction is achieved not only through robust materials and geometry but also through control systems, sensing, and fail-safe design that anticipate a spectrum of real-world conditions—from cold weather and dust to cargo with unexpected movement and operator fatigue. This holistic approach to safety is why a lift gate isn’t merely a mechanical hinge; it is a carefully choreographed system that integrates hydraulics or electrics, structural integrity, and human factors in a single, auditable package. From the outset, the design must address one persistent hazard: entrapment. Any moving barrier—whether it be a tailgate, a roll-up door, or a foldable platform—needs a dependable mechanism to detect obstructions and stop or reverse motion. In North America and many other markets, this is reflected in core safety requirements derived from standards that govern automatic doors and access systems. The central aim is straightforward: when a person’s fingers, hand, or clothing encounter resistance, the system must respond quickly to prevent injury. While the specifics can vary by region, the underlying principle remains the same: safety features must be intrinsic to the system, not retrofitted after a tragedy. As a practical matter, lift gate designers integrate sensors, torque limits, and control logic that collectively form a protective envelope around the moving components. Limit switches and travel controls provide reliable known endpoints for open and closed positions, preventing the platform from exceeding its intended range. These devices act as guards in the sequence of operation, ensuring that the mechanism cannot slam shut or rise beyond its mechanical stops, which could compromise the structure or injure nearby workers. A critical element within this protection framework is the immediate halt and reversal reaction when an obstacle is detected. This is a core concept in entrapment protection and is codified in standards that govern automated web gates, industrial doors, and vehicle-mounted lifting devices. When implemented correctly, sensors and control systems create a safety net that remains vigilant even as the gate undergoes routine wear and tear. The emblem of responsible design, however, is redundancy. A well-engineered lift gate does not rely on a single sensor or a single actuator. Instead, it uses multiple, cross-checked inputs and fail-safe states so that if one component fails, another safeguards the operator. This redundancy extends to emergency stop devices, manual release options, and mechanical interlocks that keep the gate from moving while a maintenance procedure is underway. The manual release mechanism deserves particular attention. In the event of power loss or a system fault, there must be a safe, clearly described way to unlock and operate the gate without compromising the operator. Instructions should be visible, intuitive, and aligned with the broader operator training program. The risk calculus does not stop at the hardware. Installation, commissioning, and ongoing maintenance are equally critical to safety. A gate that was safe on the shop floor can become unsafe after rough handling in the field, exposure to corrosive environments, or improper calibration. Therefore, a comprehensive maintenance routine is essential. It should include regular inspection of structural welds and pins, verification of hydraulic or electric drive performance, testing of limit switches and sensors, lubrication of moving parts, and environmental checks for ice, dust, or moisture that could alter friction, grip, or effectiveness. Documentation of maintenance activities, including date stamps and technician initials, creates an auditable trail that regulators and customers can rely on. In many markets, this level of diligence also informs purchasing decisions. Organizations that rely on lift gates for routine material handling prefer equipment that demonstrates compliance with recognised standards and explicit design documentation. This preference is not merely about avoiding penalties; it is about reducing injury risk, improving uptime, and protecting the company’s reputation. The absence of a single global standard for “Gator Lift Gates” or any particular brand underscores the importance of harmonised safety expectations. Across regions, the most relevant framework is the collection of safety standards that cover general vehicle safety, machinery safety, and the specific needs of automated rear access systems. ISO 12100, as noted, guides the risk assessment and reduction process, while other standards specify the functional safety features that must be present and tested. In North America, a core reference point for protective features in automatic doors and gates is UL 325. This standard addresses entrainment protection, emergency stop, run-time safety, and reliable start/stop behavior. Although UL 325 is written for a broad class of door and gate systems, its principles are directly applicable to vehicle-mounted lift gates performing similar motion and containment tasks. The emphasis on rapid, assured responses to obstacles, the requirement for consistent performance across a system’s operating life, and the obligation to document compliance all inform how lift gates are specified, manufactured, and operated. Even when a vehicle is deployed in industrial settings with rugged workloads, these principles hold. The design philosophy embraces not only what the gate does but how it behaves under fault conditions. A gate must fail safely, and a maintenance window must not transform a simple service procedure into a risk event. The operator’s role in safety cannot be overstated. Training translates standards into action. Operators learn to recognize warning signs, understand the sequence of operation, and appreciate the importance of keeping guards and sensors unobstructed. They are taught to test the system’s stopping behavior, to ensure that manual releases are reachable but not easily activated by accident, and to report any irregular performance promptly. The human factor often determines whether a safety feature remains effective in day-to-day use. A robust safety program combines procedural training with clear signage, audible warnings, and color-coding that communicates status, such as open, closed, or in motion. The visual and audible cues help prevent misunderstandings between workers and the machine, especially in noisy environments where reflexive actions can create new hazards. The drive toward safety is not static. Standards evolve as new technologies arrive and as industries refine their risk profiles. Manufacturers are continually updating designs to incorporate more sensitive sensors, smarter control logic, and more durable materials that can withstand harsh weather, dust, and high-cycle use. The result is a dynamic safety ecosystem that balances performance with precaution while keeping compliance transparent. In practice, selecting a lift gate for any fleet means examining more than initial cost or peak load capacity. It means evaluating how a system is designed to protect users, how it will be tested and verified, and how it will be maintained over the life of the vehicle. It means reviewing the manufacturer’s documentation for compliance with ISO 12100 and, where relevant, UL 325 or region-specific standards. It also means looking at field performance data, warranty coverage, and the availability of service networks that can perform reliable upkeep. To connect readers with practical, real-world information about liftgates, consider exploring a comprehensive overview of liftgates such as the one available here: liftgates. This reference helps frame how the theoretical safety requirements translate into daily use, maintenance, and procurement decisions. While the exact standard names and numbers may vary by jurisdiction, the core message remains constant: safety cannot be an afterthought. It must be embedded in design, validated through testing, demonstrated in operation, and reinforced through training and ongoing maintenance. For practitioners seeking authoritative specifications, the primary external resource remains the UL Solutions guidance on doors, gates, and windows, which encapsulates proven safety practices for automated barrier systems. More details can be found at UL Solutions, including the central standard that informs entrapment protection, run-time safety, and stop/run control strategies: https://www.ul.com/solutions/door-gate-window. Embracing these standards is not merely a compliance exercise; it is a commitment to protecting workers, safeguarding assets, and ensuring that a heavy-duty lift gate remains a reliable, repeatable, and safe link in the logistics chain. By aligning design, installation, operation, and maintenance with established safety frameworks, fleets can achieve lower incident rates, higher uptime, and greater confidence in the performance of their rear access systems. The result is a safer workplace, a more predictable loading process, and a chain of practices that supports the broader goal of efficient, responsible material handling in demanding environments.

Raising Efficiency: The Next Wave of Gator Lift Gates Through Automation, Electrification, and Universal Design

Gator lift gates have become more than a practical rear loading solution; they are a doorway to safer, faster, and more predictable operations across fleets that move heavy cargo every day. As payloads grow and delivery windows tighten, the liftgate no longer serves as a single function machine. It acts as a versatile interface between people, goods, and vehicles, marrying mechanical strength with intelligent systems to reduce risk and friction in the loading process. The result is a shift in how we measure efficiency on the dock and on the road. Rather than simply counting pounds moved, operators and managers now track uptime, reliability, and the quality of the loading experience. In this broader context, the future of gator lift gates hinges on three intertwined trajectories: automation and smart technologies, electrification of the powertrain, and universal usability that fits a wide range of vehicle platforms. Together, these forces redefine the liftgate as a modular, connected component that supports leaner, safer, and more economical operations across industries that rely on this technology every day.

Automation and smart technologies are rapidly transforming what a liftgate can do and how it behaves under load. Remote operation is no longer a luxury feature but a standard tool that expands the operator’s range of control. A liftgate can be commanded from a distance when space is tight or when personnel must stay clear of a potentially hazardous area. Load sensing adds a layer of precision, providing real-time feedback on remaining mass and helping to prevent overloading or unstable starts. Real-time diagnostics monitor hydraulic pressure, motor temperature, and battery health, signaling maintenance needs before a component fails. This constellation of capabilities reduces downtime and shifts maintenance from a reactive to a proactive discipline. Operators benefit from more predictable cycles, fewer injuries, and fewer delays that ripple through the supply chain. The trend toward connected liftgates also invites integration with broader fleet data ecosystems, enabling smarter scheduling and route planning. For a deeper look at liftgates, see the dedicated resource liftgates.

Electrification is accelerating the compatibility between liftgates and modern, low-emission fleets. Electric-powered liftgates align with the economics and environmental goals of fleets that are transitioning away from internal combustion power. Quiet operation is a relief in urban routes and residential pickups, where noise reduction contributes to a better neighbor experience and fewer disturbances on early morning or late-night shifts. Lower maintenance costs stem from fewer moving parts sensitive to fuel or oil changes, and the use of electric drive energy can simplify energy budgeting at the fleet level. When liftgates draw power from the same battery system that powers the vehicle, the overall energy footprint becomes more predictable, allowing operators to balance charging schedules with peak delivery windows. The result is longer duty cycles, faster turnaround times, and improved compatibility with electric commercial fleets that define today’s sustainable logistics landscape. This electrification trend also invites a closer look at how liftgates participate in vehicle telematics and predictive maintenance programs, reinforcing the value of data-driven decision making in daily operations.

A third, equally important trend is universal compatibility and ease of use. The most practical liftgates in today’s market emphasize quick deployment and adaptability across diverse truck models and body configurations. A lightweight, universal design reduces installation time and inventory complexity, supporting rapid scaling of fleets or temporary use on rental or contractor vehicles. In last‑mile delivery, where drivers may interchange between different vehicle types, a flexible liftgate becomes a critical capability rather than a luxury. The design emphasis extends beyond the gate itself to mounting hardware, interface compatibility, and detents that ensure stable, predictable operation in a wide range of environmental conditions. By prioritizing universal usability, manufacturers enable a broader ecosystem of accessories and telematics that work in concert with the liftgate to create a seamless, scalable solution for fleets that aim to stay agile as demands shift. This shift toward universal design is one reason many operators view liftgates not as a one‑off tool but as a reusable, upgradeable module that travels with the vehicle as fleets evolve.

In the broader market context, the momentum behind gator lift gates is reinforced by strong demand signals from logistics, delivery, and commercial vehicle sectors. Market analyses project a global power liftgate market value of approximately 3.86 billion USD by 2032, with a compound annual growth rate around 9.6 percent from 2026 to 2032. This growth is driven by the accelerating pace of e commerce, expanding regional trade networks, and the need for last‑mile infrastructure that can sustain higher throughput with consistent safety outcomes. Regions with dense distribution networks and high dock activity are adopting liftgates more rapidly, not only for the immediate benefits of easier unloading but for the broader operational resilience they enable. In this context, the liftgate emerges as a strategic node in the fleet technology stack, linked to maintenance planning, energy management, and fleet utilization. As technology matures, the integration of liftgates with vehicle electrical systems, telematics, and diagnostics will deepen, turning a simple loading platform into a smart gateway that contributes to safer work practices and smoother, more reliable deliveries.

The road ahead is not without challenges. Compatibility across a spectrum of vehicle frames and hydraulics requires thoughtful engineering, modular mounting solutions, and standardized electrical interfaces. Training remains essential for operators and maintenance teams as features multiply and become more integrated with vehicle data streams. While electrification delivers quiet operation and energy savings, it also concentrates on effective energy budgeting and battery management, so liftgate designers must account for the vehicle’s power profile and charging opportunities. The most successful deployments occur when equipment suppliers, fleet operators, and service networks collaborate to ensure predictable service intervals, readily available spare parts, and clear upgrade paths as new automation capabilities come online. In short, the liftgate of the near future is judged not solely by raw lifting capacity but by how well it fits into the daily cadence of the workforce, from the dock to the loading zone to the customer’s doorway.

Taken together, the evolving gator lift gate landscape points toward a future where heavy lifting is increasingly embedded in a connected, intelligent workflow. The promise goes beyond higher payloads or faster cycle times. It encompasses safer workplaces, reduced downtime, and lower environmental impact through smarter energy use and proactive maintenance. As fleets embrace connected devices and electric drives, the liftgate stands as a microcosm of the broader transformation in commercial transportation: a modular, adaptable interface that empowers people to move goods with greater confidence and less fatigue. The narrative here is not about a single device but about a cohesive ecosystem in which the liftgate, its mounting, and its data signals work in concert with the vehicle and the operator to deliver consistency, safety, and efficiency across routes and seasons.

External perspectives and further reading: For a detailed market outlook, see the Global Power Lift Gate Market Analysis and Forecast 2026-2032 on Market Research Future. https://www.marketresearchfuture.com/reports/power-lift-gate-market-1487

Final thoughts

Gator lift gates represent a vital investment for businesses reliant on efficient cargo handling and safety compliance. They not only streamline the loading and unloading processes but also mitigate risks associated with heavy lifting. As advancements in technology continue to shape the future of these systems, businesses that embrace gator lift gates will undoubtedly position themselves for greater operational success. By understanding and leveraging the benefits of gator lift gates, companies can ensure they are at the forefront of efficiency and safety in transportation.