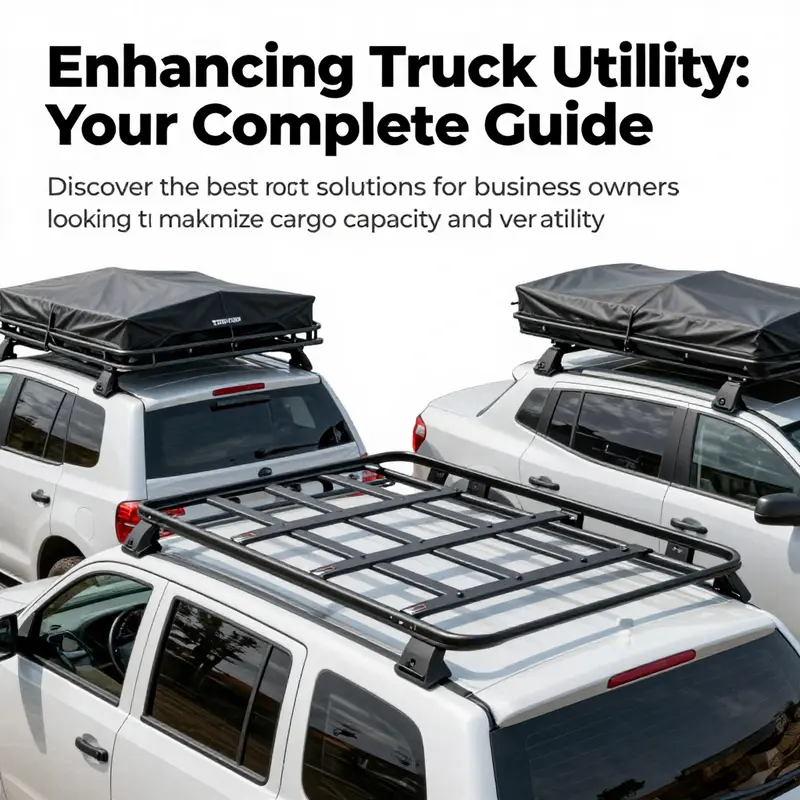

For business owners navigating the diverse demands of their industries, roof racks for trucks serve as essential tools to enhance efficiency and utility. From transporting seasonal sports gear to accommodating work-related equipment, the right roof rack can make a significant difference in operation and logistics. This guide will explore specialized ski and snowboard racks, versatile soft-shell canopies, and robust heavy-duty steel roof racks—outlining their unique benefits and considerations for various business needs. By understanding these options, you can select the best solution that boosts your truck’s versatility and performance.

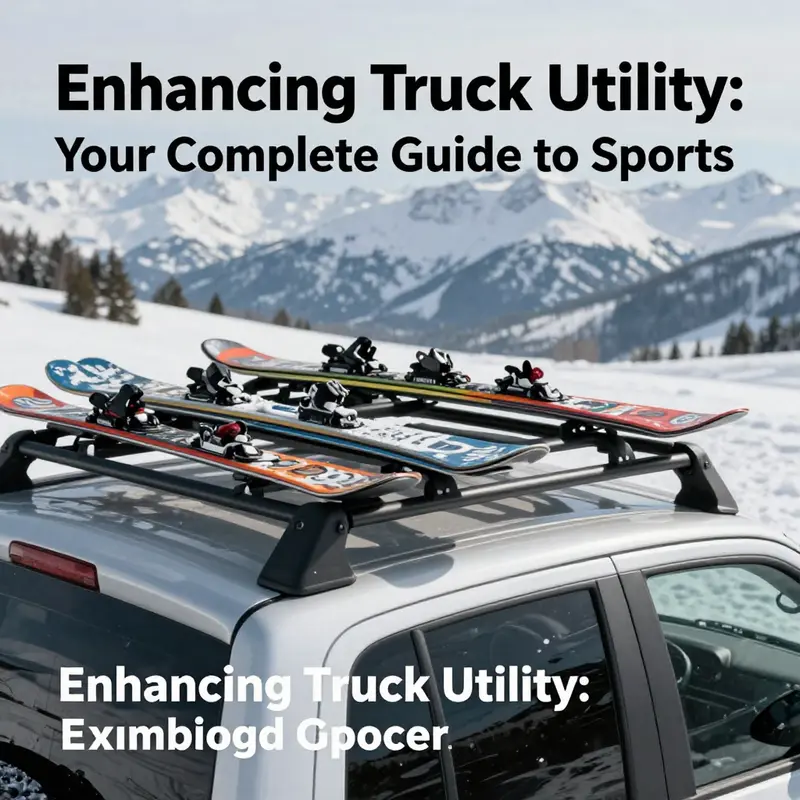

Carrying the Slopes: How Ski and Snowboard Racks Unlock Winter-Travel Utility for Trucks

The first snowfall is never just a weather event; it is a signal that plans move from the back burner to the driver’s seat. When you own a pickup and a passion for winter sports, the question shifts from whether to go to the mountain to how to get there efficiently with gear in tow. A well-chosen roof rack is not merely an accessory; it is a critical extension of the vehicle’s carrying capacity, a system designed to protect equipment from the bumps and jolts of road travel, and a means to preserve precious interior space for passengers, groceries, or camping gear. For winter trips, the right rack becomes a quiet partner in transit, one that minimizes drag, reduces wind noise, and keeps skis and boards secure at highway speeds. The concept is simple on the surface—create a dedicated cradle for long, delicate gear—but the execution is nuanced. The rack must be tailored to the vehicle’s geometry, the rack’s engagement with the vehicle’s existing crossbars, and the kind of gear most often transported. In this sense, a good ski and snowboard rack is less a one-size-fits-all solution and more a thoughtfully matched system that respects weight, leverage, and access. The design intent guides every decision—from materials and mounting to padding and locking mechanisms. A robust system protects gear from scratches and impacts while managing the stress that comes with high-speed travel and dynamic road conditions. It should also be quick to install and straightforward to remove when seasons change or when the truck serves another purpose. To achieve this balance, modern racks integrate several core features: compatibility with a range of bed configurations, protective padding to guard delicate edges, and ease of operation that lets a user switch from everyday cargo to winter gear in minutes rather than hours. A universal challenge in this space is locating a system that respects both the bed’s footprint and the vehicle’s aerodynamics. When a rack projects above the roof line, it becomes a small airfoil, and every square inch of exposed surface interacts with the wind. Aerodynamic covers and streamlined shapes are not about vanity; they are about reducing wind resistance and minimizing the whooshing and whistling that can tire drivers on long drives. The interplay between form and function is most evident in crossbar integration. A rack that clamps securely to the roof bars without drilling offers convenience and preserves the truck’s original structure. Yet the true test of a good system is how reliably it holds heavy, uneven loads in varying conditions. Snow, ice, and road salt can all take a toll on hardware, so corrosion resistance, UV stability, and robust strap systems become non-negotiable considerations. In this context, the notion of a “durable” rack goes beyond a sturdy frame. It encompasses every element: the clamps, the padding that prevents scratches on skis and snowboards, the straps that stay tight without slippage, and the protective covers that shield both gear and metal from the elements. For a winter setup, the rack must also accommodate seasonal gear with minimal retrofitting. Skis and snowboards have specific shapes and lengths, so the cradle geometry should cradle long, narrow surfaces with even pressure and without concentrating force on any single point. A well-designed rack uses soft, cushioned clamps or padded saddles to prevent edge damage while employing secure tie-downs that can be tightened with minimal effort. The combination of secure hold and quick release is essential. Drivers want to be confident that their gear will stay put through a gust on the highway and over rough back roads alike, yet still be accessible when it is time to unload at the lodge or rental shop. Within this framework, several practical realities emerge. First, the rack must fit the truck’s bed and roof configuration. Trucks differ in roof height, width, and the spacing of crossbars, and not all racks are compatible with every model. Some systems are designed to attach to existing crossbars without any drilling, a feature that adds significant value for owners who want to preserve the integrity of their factory roof and who might rotate this rack onto a separate vehicle for short trips. The ease of installation translates directly into the user’s willingness to embark on spontaneous trips when winter conditions drift toward favorable forecast windows. Second, the rack must balance capacity with safety. It is tempting to push a rack to its stated maximum load, but the combined weight of gear and rack imposes limits on how far the vehicle can travel before performance and braking are affected. In practical terms, this means distributing weight evenly and avoiding stacking items beyond the rack’s designed capacity. Long, narrow gear like skis and snowboards sit best when distributed with even lateral support along the cradle. Third, the rack should offer protection without compromising gear. UV exposure and weathering can degrade plastics and padding, so UV-resistant materials that tolerate prolonged sun and snow exposure are critical. Marine-grade polymers and weatherproof fabrics are common selections because they provide durability in a harsh winter environment while remaining relatively lightweight. In this balance of protection and practicality, the rack serves as a workshop on the move, defending edges and bindings from abrasion while offering quick, tool-free access when loading and unloading becomes part of the ritual of a mountain weekend. The best configurations also address noise and drag. Aerodynamic covers or tapered profiles reduce the wind you feel against your ears at speed, particularly important on long mountain corridors where hours behind the wheel can wear on a driver. A rack that sings with wind is not just an irritant; it can subtly alter fuel economy, cabin comfort, and even the vehicle’s stability. The design language here is restraint and efficiency: form follows function, with every curve and feature chosen to preserve highway safety while supporting the rack’s essential task of carrying bulky, awkward items with care. An important virtue of a well-conceived ski and snowboard rack is adaptability. Families or weekend explorers may trade a set of boards for a set of poles, a roof-box, or a rooftop tent, depending on the season or trip. A modular approach—cradles that accommodate skis in one configuration and boards in another, or crossbars that swap between a dedicated rack and a multi-use platform—offers the flexibility to pivot without discarding the investment. Beyond technical specifics, a critical dimension of winter transport is maintenance. Seasonal duty cycles demand attention to wear, corrosion, and the tension of straps. In salty air or slushy roads, hardware can seize or loosen if not checked regularly. A routine before and after trips—wipe down surfaces, inspect pads for cracking, test strap tension, and confirm that quick-release mechanisms function smoothly—extends the life of the rack and preserves the gear’s condition. The value proposition here is clear: a thoughtfully chosen rack not only facilitates safe, efficient transport but also preserves the life of skis, boards, and bindings by keeping them free from dents, scratches, and flexing stresses that accumulate during jarring road segments. The narrative of a winter rack is thus a narrative of fit, protection, and ease. It is about choosing a configuration that respects the vehicle’s architecture while acknowledging the seasonal nature of the gear it carries. It is about selecting materials that resist UV burn and salt exposure, and about designing contact points that cushion delicate equipment while resisting creep and slip under load. It is about recognizing that the gear itself deserves attention—edges and bases protected by padding, edges kept clear of sharp contact, bindings shielded from impact when the vehicle hits a pothole or a speed bump. To the reader seeking guidance, the practical implication is straightforward: invest in a system aligned with your vehicle’s footprint, your typical winter trips, and your tolerance for installation and removal. If you frequently drive for weekend ski getaways, a no-drill or minimally invasive mounting approach saves time and avoids altering the vehicle’s structure. If you use your truck for a broader set of tasks, including construction or fieldwork in winter, a robust, heavy-duty rack with enhanced clamps and wide compatibility may be more appropriate. The idea of a range of options helps to frame the decision-making process. You may find yourself choosing between a rigid, purpose-built ski and snowboard rack and a flexible, DIY-friendly approach that can be tailored to precise bed dimensions and mounting preferences. The DIY path—whether you frame it in wood, aluminum, or repurposed materials—can yield a cost-effective solution tailored to your exact measurements. It can also teach you about load distribution, hardware compatibility, and safe anchorage. For those who want a balance of reliability and customization, a hybrid approach often works best: start with a commercially designed cradle system that provides a solid, tested mounting interface, then add a carefully crafted DIY insert or extension that matches your truck’s bed shape and your gear’s geometry. In turning this attention to the reader’s practical needs, consider how you transport your winter equipment across a spectrum of trips. A compact weekend against a mid-winter melt or freeze cycle may favor a smaller, lighter rack that prioritizes ease of use and speed, while longer trips, multiple days, or expedition-style journeys may demand greater rigidity, corrosion resistance, and capacity. Regardless of the scenario, the reliability of the fastening system remains paramount. Straps should hold securely without slippage, buckles should function without jamming, and padding should keep your gear free from surface damage. A well-chosen rack also respects the other occupants of the vehicle. It should not intrude on seating comfort, and it should preserve visibility for the driver. The geometry of the rack must not obscure the sun or create blind spots. These considerations remind us that the best rack is not the one with the boldest design but the one that integrates most harmoniously with the truck and with the winter rituals it enables. As the season cycles from fall to winter, the rack’s role evolves from a mere carrier to a partner in planning. The moment you know a ski trip is on the calendar, the rack becomes a cue for preparation: secure the bindings, protect delicate bases with soft wraps, and ensure that the gear is distributed so it does not strain one corner of the vehicle. When you arrive at the lodge, the rack should facilitate a quick, clean unload, returning interior space to its intended use in minutes rather than hours. The practical realities of real-world use—road salt, slush, and storage for multiple days—shape how people think about the rack’s maintenance and replacement cycle. While a well-made rack can endure years of use, any component showing wear should be replaced promptly to avoid a sudden failure on a highway ramp or a windy highway shoulder. The durable, UV-stable materials commonly chosen for serious winter racks are designed to withstand repeated sun exposure and moisture without losing their shape or grip. In sum, a ski and snowboard rack for a truck is a convergence of engineering and lifestyle. It is a small but decisive part of the winter travel system, helping to maximize utility while keeping gear secure, accessible, and protected against the elements. The best racks make the mountain drive feel less like a logistical hurdle and more like a seamless extension of the outdoors you intend to enjoy. For readers seeking broader context on rack configurations and fit considerations, a deeper dive into roof-mounted options can be found here: Roof racks. This internal reference offers a practical framework for comparing crossbar systems, clamping methods, and compatibility with varying truck bed silhouettes, ensuring that you select a setup that aligns with both your truck’s architecture and your winter itinerary. While the commercial landscape for ski and snowboard racks remains diverse, the underlying principles stay constant: protect the gear, respect the vehicle, and optimize for speed, safety, and survivability in challenging weather. With the right approach, the winter road becomes not a barrier but a bridge to the slopes, where every mile of travel adds to the anticipation of fresh powder and the gratification of well-managed gear. DIY enthusiasts will find a complementary path in which careful fabrication and thoughtful mounting yield a rack that fits precisely, reduces the need for permanent alterations, and invites experimentation within safe design boundaries. Those who embrace this path should engage with reliable tutorials and community knowledge, ultimately shaping a solution that both serves and inspires. For those curious about purely do-it-yourself instructions, a widely used resource outlines practical steps for constructing a truck bed ski and snowboard rack, offering a blueprint that emphasizes safety, stability, and craft: https://www.instructables.com/DIY-Truck-Bed-Ski-Rack/. External reference: https://www.instructables.com/DIY-Truck-Bed-Ski-Rack/.

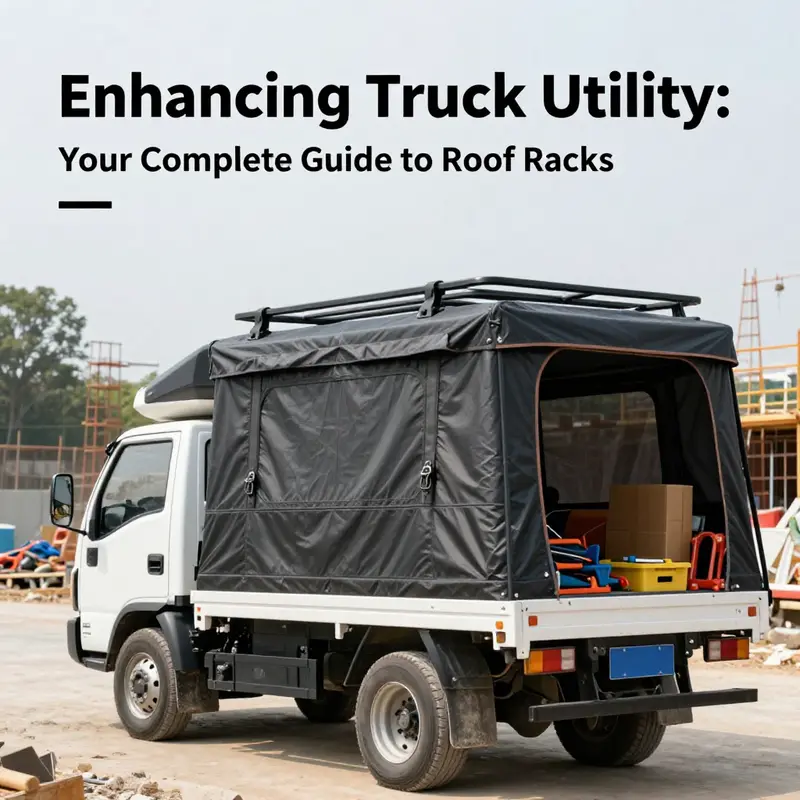

Soft-Shell Canopies on Trucks: Flexible Shelter, Weather-Resistant Accessory for a Roof-Rack World

The bed of a pickup is the hinge between wilderness and work, a space that benefits from being both protected and accessible. Soft-shell canopies for trucks reimagine how that space is guarded and grown, turning the back of the vehicle into a sheltered, adaptable zone without sacrificing the open practicality that makes a pickup truck so versatile. They are not a hard, static box but a foldable shelter that rides with the truck, ready to shield gear, shelter crew, or simply provide a dry, organized workspace. This approach sits at the intersection of utility and portability, a design philosophy that aligns with the overall idea of roof racks for trucks: extend capacity without turning the vehicle into a rigid cargo hull. Soft-shell canopies, by their nature, embrace a different balance. They emphasize quick deployment, weather resistance, and flexibility, which makes them attractive to outdoor enthusiasts, construction workers, and daily commuters who frequently carry equipment of varying shapes and volumes.

Material choice anchors the canopy’s performance. Durable, weather-resistant fabrics like heavy-duty canvas or modern polyester blends with a PVC rainfly supply the first line of defense against rain, dust, and sun. The fabric’s weave, the strength of seams, and the way the rainfly overhangs the sides together determine how well the canopy keeps gear dry during sudden downpours or as it blocks UV rays that can degrade equipment and fastenings. A well-sewn canopy resists abrasion where it contacts crossbars and clamps, and the PVC rainfly adds a dependable outer layer that sheds water while maintaining breathability inside. Practically, the material choices influence not only protection but also weight and ease of handling. Heavy fabric can resist wear longer, but it adds to the overall heft of the setup, influencing how easily the canopy can be folded, carried, and reattached after a trip. Lighter fabrics with robust coatings offer a different set of tradeoffs: easier handling with adequate weather protection for most typical conditions, but with a careful eye toward seam integrity and closure system resilience over time.

Beyond raw fabric, the canopy’s design emphasizes the relationship between shelter and access. Unlike rigid, fixed toppers, soft-shell canopies fold down into compact, stowable units. This compactness matters in several ways. It allows quick transitions between sleeping-in-gear mode and regular cargo use. It makes urban parking easier by reducing overall height, a practical advantage when entering garages or overhanging structures. And it preserves the truck’s bed access for loading and unloading without the cumbersome step of removing a bulkier rigid top. The compact profile also supports a broader fleet-wide practicality: vehicles used daily for work can still be ready for a weekend escape without a long cooldown period between trips. When deployed, the canopy provides a sheltered space that can be used for gear staging, protection against rain during a rest stop, or a quick, weatherproof workspace for planning routes, repairing equipment, or organizing tools. The seamless integration of canopy fabric and frame typically relies on a lightweight but rigid frame that can flex under wind loads yet hold its shape when staked or secured with tension straps. The result is a shelter that remains relatively rigid in gusts but folds away without the need for specialized tools or extensive labor.

In the broader ecosystem of roof-rack configurations, soft-shell canopies complement the crossbar systems and clamps that hold them in place. They are designed to work with a variety of crossbar widths and mounting footprints, enabling a flexible installation that respects the vehicle’s existing rails and roof structure. This compatibility is a crucial part of their appeal. For users who want to keep options open—whether they plan to travel light on a weekday or haul ladders or long equipment on weekends—the canopy provides a dependable, non-permanent shelter that can be added or removed without a heavy commitment to permanent alterations. For those who want a concise path to more storage or shelter capacity, a soft-shell canopy becomes part of a broader strategy rather than a standalone gadget. A canopy can be paired with other roof-mounted accessories, such as additional gear bags, modular tool boxes, or ladder racks, creating a versatile system that can adapt to changing needs and seasons. See how this approach aligns with the broader topic of roof racks in practical terms by exploring the main roof-rack resources available, which offer a deeper dive into crossbar configurations and mounting options: Roof Racks.

When it comes to practical applications, soft-shell canopies prove especially appealing to outdoor enthusiasts who value both functionality and portability. A canopied truck bed can become a ready-made field office, a shelter for gear, or a staging area for group expeditions. In bad weather, the canopy protects tents, sleeping bags, backpacks, and cooking gear from rain while keeping them organized in a single space. In dry conditions, it serves as a versatile workspace that can house a camping stove, a repair bench, or a table setup for organizing maps and gear lists. The ability to fold the canopy into a compact footprint means it can travel with the vehicle even when the truck bed is fully utilized, such as during a camping trip where the bed carries a mountain bike, a kayak, or a crates of hardware for a remotely located job site. Its weather-resistance ensures precious gear remains dry and ready, reducing prep time and increasing efficiency on the road. The canopy’s adaptability is also a boon for those who alternate between long road journeys and short day trips, providing a flexible, reliable shelter that doesn’t demand a permanent installation.

For contractors, landscapers, and tradespeople, the soft-shell canopy adds a layer of protection for tools and materials without tying up the truck’s interior. The fabric exterior acts as a shield against light rain and dust storms, while the exterior rainfly helps to keep materials dry and secure during travel. The ability to set up shelter near a worksite accelerates workflows: a laptop can stay dry while a crew consults plans, tools can be kept on a dry surface, and a portable workbench can be organized under the canopy’s shelter. The foldaway design makes it feasible to reposition the shelter as jobs progress or as weather patterns shift. Because these canopies typically rely on tension straps or inflatable foam supports rather than drilling into the roof, installation remains quick, reversible, and non-destructive. This no-drill approach is particularly appealing on rental fleets or vehicles that are used for multiple functions, where permanence would complicate scheduling or limit access to the truck bed.

A defining advantage of soft-shell canopies is their freedom from the rigidity of hard tops. A rigid top can optimize aerodynamics and provide an airy, weatherproof interior, but it often imposes a fixed footprint and a heavier, more complex installation. Canopies with flexible fabric can respond to a wider range of gear shapes and sizes, accommodating oddly sized items—think fishing nets, climbing ropes, long racking sections, or oversized suitcases—that would otherwise require repacking or a second trip. The fabric’s pliability also translates into easier handling in tight spaces. You can bend it toward the bed, fold it down across the tailgate, and still keep the rest of your system accessible. Yet, this flexibility comes with caveats. While the shelter is protective, it typically does not offer the same absolute weather sealing as a hard shell in extreme conditions. Storm winds, hail, or prolonged exposure to driving rain can test any shelter. The tradeoff, then, is a lighter, more adaptable solution that thrives under a mix of reasonable weather rather than a high-wind, heavy-rain scenario. For many owners, this is a practical compromise between accessibility, cost, and performance.

No discussion of soft-shell canopies would be complete without addressing installation realities. A fundamental strength is the availability of no-drill mounting options that exploit existing roof rails or bed-corner points. The clamp-based systems that secure the canopy harness the roof’s profile without permanent alteration, a feature that resonates with people who are cautious about vehicle modification or who rotate vehicles for business and leisure. The clamps and tensioning systems must distribute load evenly across the roof to avoid concentrate stress points on the metal or paint. In practice, this means evenly spaced clamps, robust fabric tie-downs, and thoughtfully placed anchor points that minimize movement in transit. The canopy’s framing usually includes reinforcements at stress points where fabric folds occur, reducing wear during repeated deployments. Maintenance then becomes straightforward: inspect seams for signs of wear, refresh waterproofing where needed, and ensure zippers or closures operate smoothly after exposure to dust and moisture. Drying, in particular, matters for prolonged canopy life; letting the fabric dry completely before folding prevents mold and keeps the color and texture from degrading over time.

Careful packing and storage also extend the canopy’s life. When not in use, it should be stored in a dry, shaded location to prevent UV degradation that can harden fabric or fade color. Anti-mold treatments or breathable storage sacks can help; however, the practical rule is simple: a dry canopy lasts longer. The fabric’s surface should be kept clean—dust and dirt can abrade seams and zippers over time, especially during out-of-town trips where rough roads invite more debris. A light cleaning with a soft brush and mild soap, followed by thorough drying, preserves the canopy’s integrity. Since the canopy folds, it’s important to practice how it folds to avoid creasing fabric excessively. A consistent folding pattern reduces wear along the same lines and helps keep the fabric’s flexibility for years of use. When used in combination with a roof-rack system, the canopy’s care extends to the crossbars as well. Regularly inspecting clamps for loosening, cleaning contact surfaces, and ensuring rubber gaskets or padding are intact protects both the canopy and the vehicle’s finishing.

The end result, for many owners, is a shelter-and-storage solution that travels with the truck between jobs, trips, and daily duties. It allows a portable, weather-resistant zone that can be set up to host a small worktable, a gear drop-off point, or a quiet corner for planning routes on a road trip. The versatility is a natural partner to the broader concept of roof racks for trucks, where the aim is not only to haul weight but to support dynamic, seasonal needs. The canopy and its accompanying crossbar system therefore become part of a larger ecosystem of modular, adaptable gear. It is this ecosystem that makes a soft-shell canopy a compelling choice for those who want to keep a vehicle ready for anything—whether the next morning brings a rainstorm, a dry weekend for camping, or a construction assignment that requires protection from the elements.

From a design perspective, soft-shell canopies embody a balance between rugged durability and user-friendly operation. The materials are chosen for their resilience and weather resistance, yet the assembly emphasizes ease of use and rapid readiness. For the user, this translates into fewer hours spent fiddling with hardware and more time enjoying the cargo and the road. The canopy becomes a small, protective room that travels with the vehicle, a flexible space that expands the truck’s capabilities without obstructing daily driving or the use of the bed. The canopy is not a destination in itself; it is an enabling accessory that unlocks new ways to approach travel, work, and recreation. That is the core appeal: a canopy that folds away when it is not needed, yet appears when a shelter, a work area, or a dry staging space is required.

In the context of a broader search for roof-rack solutions, soft-shell canopies illustrate the value of modular design. They invite users to think beyond a single function and toward a layered approach to capabilities. A truck with a soft-shell canopy can handle a range of tasks—from transporting sensitive equipment to staging a field kitchen, all while preserving the ability to access the bed quickly. This integration of shelter and storage, wrapped in a featherweight, no-drill package, aligns with the modern demand for flexible, multi-use vehicles. It also resonates with a growing awareness that gear and vehicle performance benefit when systems are designed to work in concert rather than as separate add-ons. For readers seeking to place this chapter within a larger conversation about how to choose, configure, and use roof racks for trucks, the following link points to a broader overview of roof-rack options and considerations: Roof Racks.

For readers exploring the material depth behind these choices, the soft-shell canopy is more than fabric and straps. It represents a philosophy of pragmatic protection—one that weighs weather exposure against the need for swift access and adaptability. The fabric, the seams, the frame, the tensioning system, and the rainfly all contribute to a cohesive whole that can respond to changing conditions. A canopy that folds into a compact unit when not in use is a tangible asset in daily life. It reduces the friction of transitioning from work mode to adventure mode, cutting down setup time so people can get to the task at hand, whether that is loading equipment for a climbing trip, setting up a dry camp after a long drive, or simply protecting a ladder and power tools on a remote job site.

In sum, soft-shell canopies present a compelling blend of protection, portability, and practicality. They are designed to complement, not replace, the broader roof-rack system that supports them. They don’t attempt to seal every corner of the weather out, but they protect the gear and people within a portable shelter that moves with the vehicle and folds away when not needed. They invite a mindset of flexible storage and adaptable shelter, allowing truck owners to tailor their rigs to the patchwork of tasks life throws at them. If you’re weighing options for your next truck upgrade, consider how a soft-shell canopy could fit into your existing roof-rack setup, how easily you can deploy it, and how well it protects the gear that matters most during your journeys. And as you plan, you might find it helpful to explore the wider landscape of roof-rack configurations and accessories, to ensure you’re building a system that is cohesive, scalable, and future-ready.

External resources that shed light on the broader materials and design considerations can be found here for deeper reading: https://www.outdoorgearlab.com/rooftop-tent-materials-and-features/.

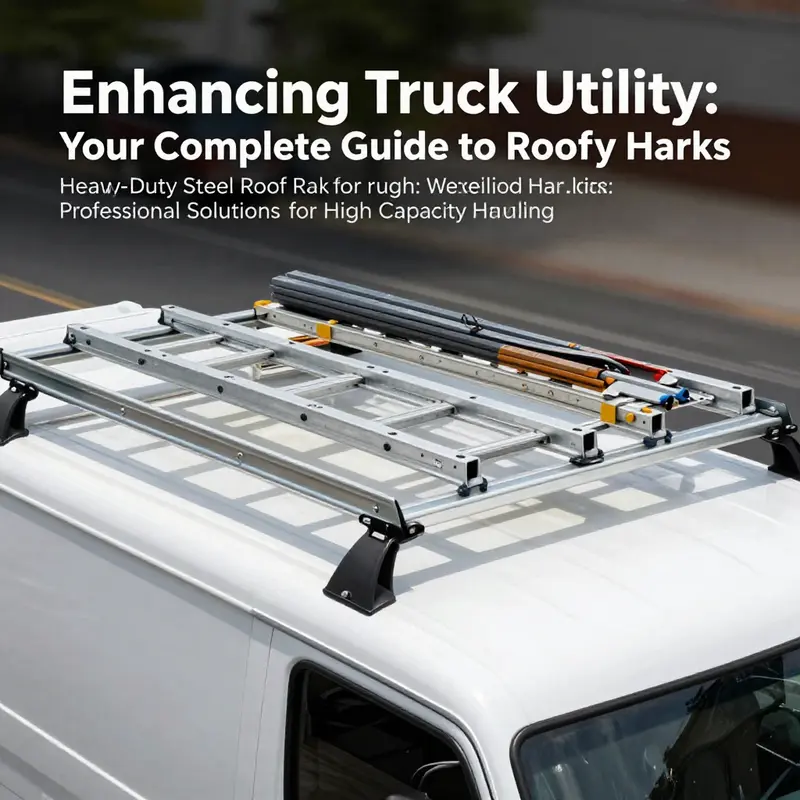

Heavy-Duty Steel Roof Racks for Trucks: Professional Solutions for High-Capacity Hauling

Heavy-duty steel roof racks for trucks stand as purpose-built solutions that meet the demanding needs of professionals who rely on every mile to count. In construction yards, on fleet operations, and across rugged outdoor work sites, these racks extend a vehicle’s cargo envelope far beyond what a standard bed can hold. They are not mere add-ons; they are integral components of a well-planned logistics chain. The steel framework delivers enduring strength, resistance to the harsh realities of job sites, and the kind of reliability that translates into fewer delays and more consistent schedules. When a crew needs to move planks, ladders, heavy tools, or even large-scale equipment, the right rack system can transform a truck into a versatile mobile shop. The emphasis here is on capacity, but capacity without control is a hazard. Steel racks designed for professional use balance high load limits with secure mounting, weather tolerance, and thoughtful geometry that keeps a vehicle’s center of gravity within safe bounds. In the long run, this harmony reduces maintenance costs, minimizes downtime, and improves overall safety for both drivers and crews. The result is a system that does more work with less fuss, letting teams focus on their tasks rather than wrestling with their transport method.

From a design perspective, heavy-duty steel roof racks are engineered to weather the realities of varying climates and relentless use. Steel, when properly treated, offers a combination of tensile strength and fatigue resistance that lightweight alloys can struggle to match in the same price bracket. A rack built from high-strength steel typically features a reinforced frame, with cross members that distribute load evenly across the roof and down into the attachment points. A weather-resistant finish—whether galvanized, powder-coated, or coated with a protective polymer—helps defend against corrosion, surface wear, and the inevitable contact with weather, road salt, and industrial dust. The ability to resist moisture and temperature swings is not merely about longevity; it also preserves the integrity of the cargo itself. Structural stiffness matters as well. Racks that maintain minimal flex under load keep cargo aligned and reduce the risk of gear shifting or rubbing against critical vehicle components at highway speeds. For operators who regularly rack up long hauls, this rigidity translates into smoother travel, lower wind-induced fatigue on components, and a calmer ride for the driver.

Load capacity is the cornerstone of any serious discussion about steel roof racks. While consumer-grade racks emphasize convenience, professional-grade systems focus on dependable performance under substantial weight. In practical terms, a robust steel rack can comfortably handle loads that exceed one thousand kilograms in total mass, depending on the vehicle’s roof structure, mounting hardware, and the crossbar configuration. This capability opens up a wide array of applications: bulky camping gear, stacked tool boxes, long lengths of lumber or piping, and large insulation or equipment materials can find a secure home above the cab. The higher the load ceiling, the more attention must be paid to load distribution. A well-designed system uses a combination of reinforced side rails, crossbars, and anchor points that work together to maintain stability during acceleration, braking, and cornering. Some configurations even incorporate modular or foldable elements to maximize space utilization without compromising safety. For instance, spaces can be allocated for rigid tools on one side and softer, more delicate items on the other, with dividers locking into place to prevent shifting during transit. While the capacity numbers speak loudly, the practical takeaway is that high-capacity hauling demands a holistic approach: accurate weight assessment, even distribution across the rack, and a conservative planning mindset to account for dynamic forces acting on a moving vehicle.

Installation and mounting methods are another critical axis along which steel racks are differentiated. A professional setup often favors mounting schemes that avoid permanent alterations to the vehicle’s structure while delivering dependable security. Many heavy-duty steel racks are designed to clamp onto roof rails or integrate with rain gutters, allowing for installation without drilling. This no-drill approach reduces the risk of water intrusion and preserves the vehicle’s resale value, while still providing industrial-strength holding power. In more complex configurations, a rack may bolt to reinforced roof structures or base rails that spread the load across multiple load points. The choices matter: the right mounting method protects the roof’s protective coatings, reduces flex, and minimizes the likelihood that vibrations will loosen fasteners on rough roads. The engineering challenge is to ensure that attachment points remain accessible for maintenance checks without creating snag points that can catch branches or equipment in off-road applications. In practice, operators learn to verify that every clamp, buckle, and anchor has been tightened to the manufacturer’s recommended torque after the first few miles and then checked at regular intervals on long trips.

Alongside structural resilience and mounting practicality, safety and cargo security are inseparable from the identity of a professional steel rack. A system designed for high-capacity hauling must integrate robust tie-down options, corrosion-resistant hardware, and protective features that shield both gear and vehicle. Tie-down points, when properly utilized, convert loose piles of equipment into a controlled load, reducing the risk of shifting, scuffing, or loss on the highway. Protective elements such as mesh panels or framework guards can help prevent items from sliding into the edges of the vehicle or against painted surfaces. A carefully engineered rack also minimizes wind noise and drag. Aerodynamics may not be the first concern in a work context, yet even modest improvements in wind resistance can yield meaningful fuel savings and quieter operation on lengthy journeys. In practical terms, this means selecting a rack system with thoughtfully contoured crossbars and streamlined edge profiles, rather than a flat, aggressively angular silhouette. The combination of secure anchors, protective design, and aerodynamic refinement results in a product that serves as a reliable platform for daily tasks rather than a high-maintenance complication on the road.

For professionals, the right steel rack is more than a single feature set; it is a versatile platform that adapts to the changing demands of a project. A typical week might see a truck used for transporting bulk materials one day and delicate, high-value tools the next. A modular approach—where add-ons can be swapped or reconfigured—enables this fluidity without requiring multiple vehicles or brittle, one-size-fits-all solutions. In a warehouse or fleet setting, racks may be designed to stack or nest with other units, enabling efficient storage when trucks are parked and not in use. The ability to stack or slot components in a way that preserves air flow and reduces clutter is a genuinely practical advantage. The emphasis here is on efficiency, not extravagance. A well-chosen steel rack helps teams optimize their loading plans, minimize trips, and shorten the window between arrival and deployment of equipment on a job site. This is where steel’s legendary durability translates directly into real-world productivity, turning transportation into a dependable part of the workflow rather than a bottleneck.

From a standards and compliance perspective, professional-grade steel roof racks are often designed to meet strict environmental and safety criteria. Environmentally responsible practices are increasingly embedded in the manufacturing and packaging of equipment meant for widespread industrial use. For example, some tool-storage systems carried on truck racks are developed with packaging and end-of-life considerations aligned to European packaging directives, signaling a broader commitment to sustainable production and responsible disposal. For buyers, these standards translate into greater confidence that the system can endure years of exposure to sun, rain, and road grime without succumbing to premature wear. The reality is that the most durable racks are not simply rugged by accident; they are the result of deliberate material choices, protective coatings, and assembly practices that emphasize long-term performance and safety. This awareness is especially important for fleet managers who must balance upfront purchase costs with lifetime maintenance, depreciation, and downtime.

In terms of procurement, organizations typically look for steel racks that offer clear load specifications, robust warranty terms, and verifiable supply-chain transparency. A reputable supplier will provide detailed mechanical data, including load distribution coefficients, mounting guidelines, and inspection intervals. The best systems also come with clear documentation about corrosion protection, heat resistance, and how the rack behaves under dynamic loads in real-world conditions. When evaluating options, many teams opt for sources that offer warranties of sufficient length to cover potential field use. They also seek assurance that the products have been tested under standards that reflect their industry’s realities, such as vibrations from uneven road surfaces or the impact of sudden braking. For those who require cross-border and cross-market compatibility, packaging and regulatory compliance can be decisive factors—ensuring that the system meets the expectations of international logistics and has been designed to support global operations.

Purchasing considerations for heavy-duty steel roof racks extend into the practicalities of sourcing and support. In a competitive market, the availability of verified suppliers, transparent specifications, and accessible customer service matters as much as raw capacity. Buyers should seek out options that provide manufacturing detail and post-sale support, including easy replacement parts, readily available fasteners, and serviceable clamps. A prudent approach is to compare multiple configurations that share a common structural philosophy—steel frames with reinforced joints, corrosion protection, and well-calibrated load paths—without becoming locked into a single, rigid system. This flexibility matters when a fleet expands or when a business pivots to accommodate different kinds of projects. It is also wise to consider how a rack integrates with existing crossbar systems and whether it supports future upgrades, such as additional modular compartments or weatherproof storage pockets. To practitioners, the value lies in predictable performance, predictable maintenance needs, and the assurance that the rack will perform as intended across a broad range of job site conditions, from desert heat to snowy mountain passes. Throughout the decision-making process, the emphasis remains on matching the right level of strength to the task at hand while ensuring safe, efficient, and compliant operation on every voyage.

For professionals seeking a complete picture of how steel roof racks fit into a holistic vehicle configuration, the topic is rarely isolated to raw strength alone. Integration with crossbars, roof rails, and accessorial equipment shapes the overall utility of the setup. A well-chosen rack is designed to complement a vehicle’s aerodynamics rather than fight against them. It works in concert with ladder racks, tool carriers, and even soft-shell canopies in some configurations, creating a modular ecosystem that can be tailored to the user’s workflow. In practice, this means choosing a system whose dimensions, mounting footprint, and attachment hardware align with the truck’s roof profile and the expected load profile. It also means thinking ahead about how cargo will be secured and accessed; a rack that makes loading and unloading cumbersome will soon become a bottleneck rather than a strategic asset. When professionals consider all of these factors together, they can achieve a balanced solution that maximizes payload, minimizes maintenance, and keeps operators safer on the job.

To connect these ideas with practical, on-site experience, readers may explore our broader discussion of roof racks and their role in vehicle utility. In that broader guide, the emphasis is on how a rack system integrates with a truck’s existing architecture and how the user can optimize both storage and access. See the Roof Racks guide for a concise overview of crossbar systems, weather considerations, and mounting options that complement the steel rack philosophy described here. This interlinking reinforces a unified understanding of how high-capacity hauling fits into everyday work routines and long-term asset management. Roof Racks

In sum, heavy-duty steel roof racks for trucks represent a strategic investment for professionals who rely on consistent, high-capacity hauling. They merge strength and resilience with intelligent design to deliver a platform that can adapt to diverse tasks, environments, and work tempos. The best choices respect the realities of dynamic loads, weather exposure, and the need for rapid, safe access to gear. They acknowledge that capacity is only valuable when it is matched by stability, ease of use, and predictable performance over time. For fleets and field teams alike, the payoff is measured not merely in kilograms carried, but in the reduced risk, improved uptime, and enhanced reliability that follow a well-chosen, professionally engineered rack system. External references and supplier options can further illuminate the landscape for buyers who want a robust, future-facing solution that scales with their operations. As with any asset that travels with a vehicle, the true test is whether the rack endures beyond the first season and continues to deliver on the promise of high-capacity hauling with minimal fuss. For those seeking broader supplier perspectives and practical specifications, an example listing exists on a major industrial marketplace that aggregates verified suppliers, detailed specs, and warranty terms to support informed purchasing decisions.

External reference: https://www.alibaba.com/product-detail/Heavy-Duty-Steel-Roof-Rack-for-Truck1600739882573.html?spm=a2700.productlist.0.0.7a3f7c4dJZjYqX

Final thoughts

Selecting the right roof rack is a crucial step for business owners looking to enhance the functionality of their trucks. Whether you need specialized racks for seasonal gear like skis and snowboards, versatile soft-shell canopies for weather resistance, or robust heavy-duty solutions for demanding hauling tasks, each option offers unique advantages tailored to your operational needs. By understanding these different roof racks, you can make informed decisions that bolster your business’s efficiency and adapt to various demands seamlessly.